Have you ever found yourself marveling at the endless possibilities 3D printing holds for the future of design and manufacturing? It’s as if we’re living in a world where your imagination is the only limit—except, as it turns out, materials can often be the real boundaries. However, what if I told you that new developments in material science are pushing those boundaries, transforming what we once thought was impossible into reality? These advancements, particularly in 3D printing filaments, are not just a flash in the pan; they are revolutionizing the field, turning futuristic dreams into today’s possibilities.

The Transformative Power of 3D Printing

3D printing has been like the cool kid on the block—everyone wants to know what it’s up to next. Distilled down to its essence, 3D printing, or additive manufacturing, is where you take something digital and turn it into a physical object layer by layer. Think of it as digital origami but with plastics or even metals. It’s been the darling of prototypers, hobbyists, and engineers who see this as more than just a neat trick, but as a gateway to efficiency and customization we never thought possible.

The beauty of 3D printing is that it gives you the power to create complex, intricate designs that would be impossible or prohibitively expensive using traditional manufacturing processes. But while we’ve seen countless innovations thanks to 3D printing’s versatility, the full potential was still bogged down by the constraints of the materials we have had available—until now.

Material Science: The Game Changer

Here is where material science enters the picture like a deus ex machina, shifting the entire scene. In the world of 3D printing, the filament you choose is your canvas. From strong yet static plastics to flexible, rubber-like materials, these are the building blocks of the objects you print. But recent breakthroughs in filament materials are transforming what can be created. These aren’t just nuanced improvements—they are providing drastically new capabilities from increased flexibility to unparalleled strength.

What Makes a Filament Special?

It’s not mere hype to say that the quality of a filament makes or breaks the integrity of a printed object. In the early days, we only had basic options like PLA and ABS. PLA, derived from cornstarch, allows for ease of use and bio-compatibility. ABS, on the other hand, offers more durability and heat resistance. But both have limitations that left designers wanting more. The shortcomings of these materials sparked the imaginations of scientists who started dreaming up innovative new compounds that could unlock greater potential in 3D printed works.

Components and Comparisons

Here’s a table breaking down some of the more traditional filaments alongside some of our new shining stars:

| Filament Type | Composition | Properties | Ideal Uses |

|---|---|---|---|

| PLA | Polylactic Acid | Biodegradable, easy to print, low melting point | Prototypes, models |

| ABS | Acrylonitrile Butadiene Styrene | Durable, high resistance to heat, more challenging to print | Automotive parts, tools |

| PETG | Polyethylene Terephthalate Glycol-modified | Tough, chemical resistant, requires careful handling | Food containers, industrial applications |

| Carbon Fiber | Composite of carbon filaments | High strength-to-weight ratio, stiffness, dimensional stability | Aerospace, high-performance automotive |

| Wood Fill | Blend of PLA and wood fibers | Aesthetic similarity to wood, not stronger or easier to handle | Decorative pieces, art installations |

| Metal Fill | Alloy composite | Conducts electricity, enhances rigidity, but requires expertise | Custom electronics, jewelry |

The Uprising of New Filaments

Superpower-Infused Filaments

Let’s get into the whole new roster of superpower-infused materials entering the 3D printing market. Change is always around the corner, and some innovations are making this list feel as though we’re now operating with a technological cape draped over our shoulders.

Conductive PLA

Conductive PLA is, quite frankly, a nerd’s dream come true. By blending PLA with conductive materials such as carbon or graphene, you get a filament that can be used for low-voltage electrical applications. Imagine printing your own circuit boards! Alright, so maybe I’m not rewiring my house yet, but it offers engineers the opportunity for some nifty prototyping without needing a separate assembly of wiring.

Graphene Enhanced Filaments

Speaking of graphene, have you ever wanted to feel like you’re on the cutting edge of a scientific breakthrough? Because working with graphene might just do it for you. Lighter than air and stronger than steel, introducing graphene flakes into various filament materials has created compounds with incredible durability and flexibility. Graphene composites may very well change the face of industries like aerospace, all while lightening their load.

The Rise of Biodegradable Elegance

Sustainability is something that feels almost obligatory in today’s narrative, and thank goodness for that. Clearly, Mother Earth could use a win these days. Filaments created from biodegradable materials are rolling in like a breath of fresh air—or perhaps more appropriately, like that delightful scent of rain after a long drought.

Plant-Based Filaments

For those itching for green options, plant-based filaments are turning heads. These filaments combine traditional printability with eco-friendly materials, such as bio-built plastics from algae or other renewable resources, providing a more sustainable option. The idea here isn’t just a novel pathway for hobbyists but real industrial applications looking for greener building blocks.

True Industrial Powerhouses

Filaments developed for industry-level applications are no less transforming. Consider polycarbonate blends that offer shatter-resistant properties or soluble support materials that dissolve away for highly complex geometries.

Ultem and PEEK

Ultem and PEEK enter the fray as renowned for their incredible strength and thermal resistance. Capable of creating parts with the robustness usually reserved for metal, these filaments open up avenues for innovation in fields such as aviation, automotive, and beyond. Imagine crafting machinery parts without sacrificing any required integrity.

Flexible Filaments for Dynamic Applications

Ever wanted to print something squishy or resistant to impact? Thermoplastic elastomers (TPE), SambaFlex, and other similar filaments can give your projects elasticity and tactile qualities you can’t get from more rigid filaments.

Overcoming Challenges with New Materials

Despite these new avenues, it’s not a walk in the park. Each filament comes with its idiosyncrasies. Whether it involves high-temperatures to mitigate warping or solving brittleness with tweaks in composition, the journey to material mastery isn’t always straightforward. But the spirit of innovation often thrives in overcoming challenges.

The Dance of Technology and Science

Let’s not forget, the dance of technology and science often tangoes its way to unexpected stumbles, yet recovery and resilience meet these innovations stride for stride. The fact that a lab mistake can lead to an unpredicted filament property providing unforeseen uses isn’t uncommon. Trial, error, and discovery dance together quite well.

Real-World Applications: Seeing is Believing

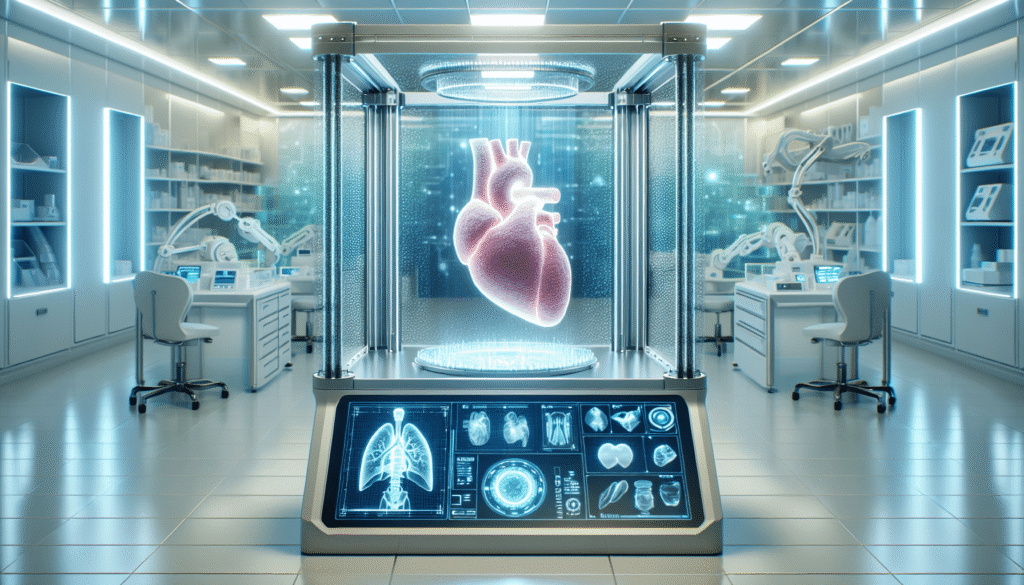

Medical Innovations

Remember when I spoke about flexibility earlier? In the medical field, 3D printing with bio-compatible elastomers is transforming prosthetics. We’re talking customized, patient-specific designs enhancing comfort and functionality, changing lives without the traditional aesthetic or functional compromises.

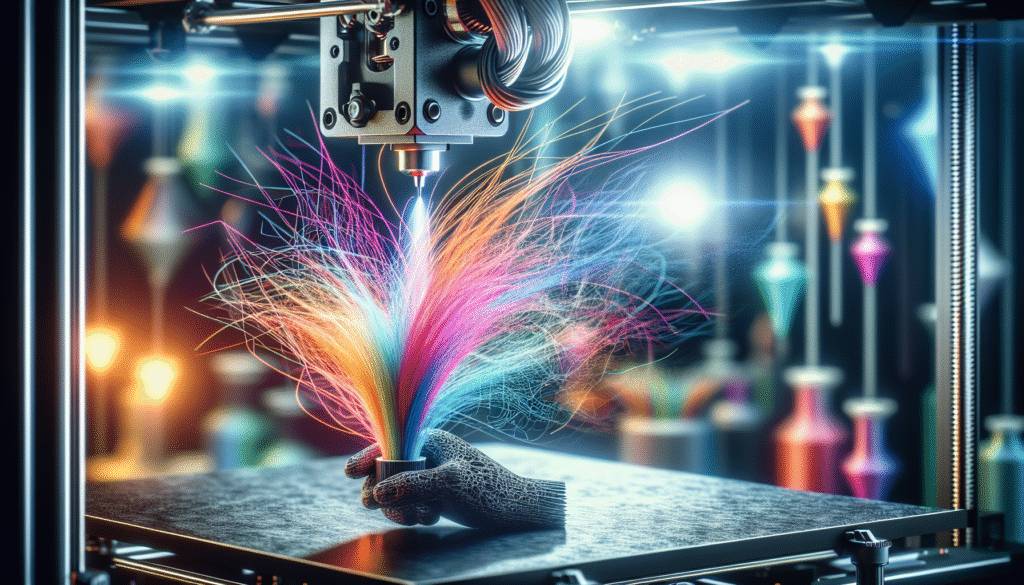

Art and Fashion: Creative Freedom

These future-forward materials are like an artist’s palette expanded a hundred-fold, birthing avant-garde sculptures and bespoke fashion pieces. Picture shoes tailored to your comfort through personalized designs, all without sacrificing the flair of a catwalk-worthy ensemble!

Automotive and Aerospace Frontiers

Aerospace advancements rest heavily on weight reductions and increased strength ratios. Lighter, stronger materials allow for less fuel consumption, translating to fewer emissions. Who knew your next filament choice might just affect the environment in such a meaningful way?

The Road Ahead with These Breakthroughs

It’s plain to see that material science is far from finished in the innovation sector. Creating less costly, more sustainable, and efficient filament compositions remains on the docket. While there are both success and setbacks along the corridors of innovation, it’s undeniable that these waves of change are going to be consequential. The surge in filament possibilities ignites a thrilling, yet challenging, manifestation of creativity and practical industry solutions alike, and I find myself excited to witness what’s next.

In the world of 3D printing, material science not only extends an artist’s canvas but also a scientist’s toolkit, redefining what we thought we could 3D print. These material innovations are changemakers, touching everything from art to airplane parts and beyond. It leaves me wondering, just what will we build tomorrow?