Have you ever wondered what sets dye-sublimation apart from direct-to-garment printing? We often find ourselves choosing between these two methods when it comes to printing vivid designs on fabric. Both processes have their unique strengths and weaknesses, and understanding these can help us make informed decisions tailored to our creative and business needs. So let’s gather around and chat, in a friendly and informative way, about the ins and outs of dye-sublimation and direct-to-garment (DTG) printing.

What is Dye-Sublimation Printing?

Dye-sublimation printing is like a magic trick for textiles. We start with a specially coated paper and solid dye. Under the influence of heat and pressure, this dye turns into a gas and bonds with polyester fabric at the molecular level. Imagine all those mornings when we’re trying to turn ourselves into morning people. Sometimes, all it takes is a little heat.

The magic of dye-sublimation lies in the way it integrates into the fabric itself, which stands apart from merely sitting on top of it. This results in images that are durable, vibrant, and resistant to fading, even after repeated washings. However, our mannequin doesn’t come without its own set of quirks, which we’ll explore further.

The Parent Trap of Polyester

While the results are stunning, dye-sublimation has an enduring love affair with polyester. It’s where it works best. Those of us who love the feel of cotton may feel a tad left out. Hence, while polyester blends can sometimes accommodate us, it’s pure polyester that really sizzles in dye-sublimation.

A Rainbow of Possibilities

This printing method brightens our lives with an impressive color range and vibrancy. Dyes blend seamlessly, producing gradients and bright colors that can make us the envy at the office party.

What is Direct-to-Garment (DTG) Printing?

In direct-to-garment printing, a digital inkjet printer applies ink directly to the fibers of the fabric, much like inviting a guest to sit and chat rather than wave from a distance. DTG is ideal for customizing apparel, especially when we yearn to experiment with various colors and intricate designs.

The Fiber Whisperer

Unlike the polyester-specific nature of dye-sublimation, DTG is the fiber’s confidant. We can print on cotton, bamboo, hemp, and other natural fibers, providing a home for all fabric types. Whether we’re t-shirt enthusiasts or hoodie lovers, there’s versatility in our wardrobe with DTG.

The Color Conversation

When it comes to colors, DTG manages a decent discussion. The print quality is detailed enough to capture our imagination, allowing nuances and subtlety in every nook and cranny.

Pros & Cons: Dye-Sublimation vs Direct-to-Garment Printing

Since both methods have their share of fans, let’s sit down and chat about what we love and what we could do without.

Dye-Sublimation Pros

- Durability: The colors won’t fade or crack over time, promising us long-lasting friendships with our apparel.

- Vibrancy & Clarity: Designs are crisp and colors are vibrant, putting a little pep in our sartorial step.

- All-over Printing: Can provide seamless designs over the entire fabric.

Dye-Sublimation Cons

- Limited Fabric Types: Primarily works with polyester, leaving other fabrics out of the conversation.

- Initial Cost: Setting up for sublimation can dig a bit into our wallets, especially when we’re just starting out.

DTG Pros

- Fabric Versatility: Cotton, silk, polyester — there’s room for any fabric friend here.

- Detailed Designs: Finely detailed prints with a good enough resolution to show off our creative side.

- Low Setup Cost: Ideal for small runs and startups, giving us a chance to experiment without intimidating costs.

DTG Cons

- Less Durability: Though detailed, designs may fade with multiple washes, like a fleeting summer romance.

- Speed: For larger orders, DTG may not keep up with our ambitious timelines.

Here’s a comparative table that lays it out clearly for us:

| Feature | Dye-Sublimation | Direct-to-Garment (DTG) |

|---|---|---|

| Durability | High | Moderate |

| Vibrancy | Very High | Moderate to High |

| Fabric Compatibility | Polyester Only | Multiple Fabric Types |

| Setup Cost | Higher | Lower |

| Detail | Moderate to High | Very High |

| Speed | Fast for Large Runs | Slower for Large Runs |

Breaking Down the Costs

When it comes to breaking our piggy banks, it’s essential to consider both setup and operational costs.

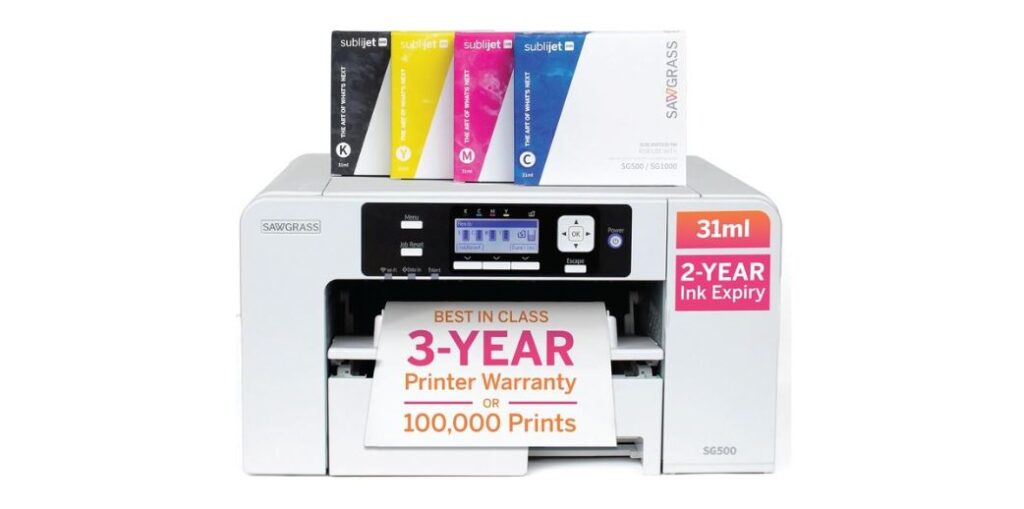

Dye-Sublimation Costs

Starting with dye-sublimation, the initial investment in equipment can be higher. We’d need sublimation printers, heat presses, sublimation paper, and suitable inks. The magic of molecular-level printing comes with its price tag, but we must remember: pay the fiddler to hear the tune.

DTG Costs

On the flip side, DTG has a lower initial cost, making it the kind of guest who brings their delightful company without expecting a surcharge. While inks and maintenance costs vary depending on volume and complexity, the approachable entry barrier makes it a captivating choice for small businesses and personal projects.

Production Scale and Speed

Depending on whether our brains are wired for fast-paced dynamics or say, artisanal storytelling, we will want to consider speed and order size capability.

Dye-Sublimation Efficiency

For large batches, dye-sublimation rides the highway of efficiency, hitting top speeds and leaving no room to dawdle. Quick heat transfers equip it for bulk orders, ensuring we stay ahead of our business calendars.

Navigating DTG’s Pace

In contrast, DTG takes a more intimate and detailed approach, allowing for lower quantity runs but at a sometimes leisurely pace. It appreciates the art of what it calls ‘slow customizing’, perfect for those special one-off creations or very small batches.

Sustainability: Our Responsibility

In these enlightened times, the ethical responsibility to our planet is almost as trendy as the outfits we print. Both processes speak to our conscience but walk slightly different paths in doing so.

Dye-Sublimation and the Environment

This method, bound closely with synthetic fabrics, dances on the sustainability tightrope. Polyester garments, if not recycled, add to environmental concerns. Yet, with a long vest, a durable garment may need fewer replacements.

DTG’s Eco Credentials

DTG, often using water-based inks, claims a more eco-friendly position and, if combined with organic or recycled materials, earns a green badge for its efforts. Still, energy use is something we must always weigh.

Which To Choose?

So how do we decide? Standing at this meandering crossroad, a multitude of factors come into play — cost, intended project scale, fabric compatibility, or perhaps the environmental footprint we wish to leave behind.

Tailoring to Our Needs

Assessing our specific needs becomes paramount. Are we looking for durability and vibrancy, or does our creativity lean towards intricate designs and fabric flexibility? Are we dreaming of large collections, or are we focused on custom bespoke pieces?

Conclusion

The delightful dances of dye-sublimation and direct-to-garment printing bring unique advantages and challenges. As we venture forth, informed choices can lead us down the path that suits our passion projects or business endeavors best. Crafting with color, creativity, and conscience ensures our printed narratives make a bold statement, whether nestled in polyester’s embrace or the cozy folds of cotton. Whatever we choose, let’s hold it dear and print out a story that’s authentically ours.