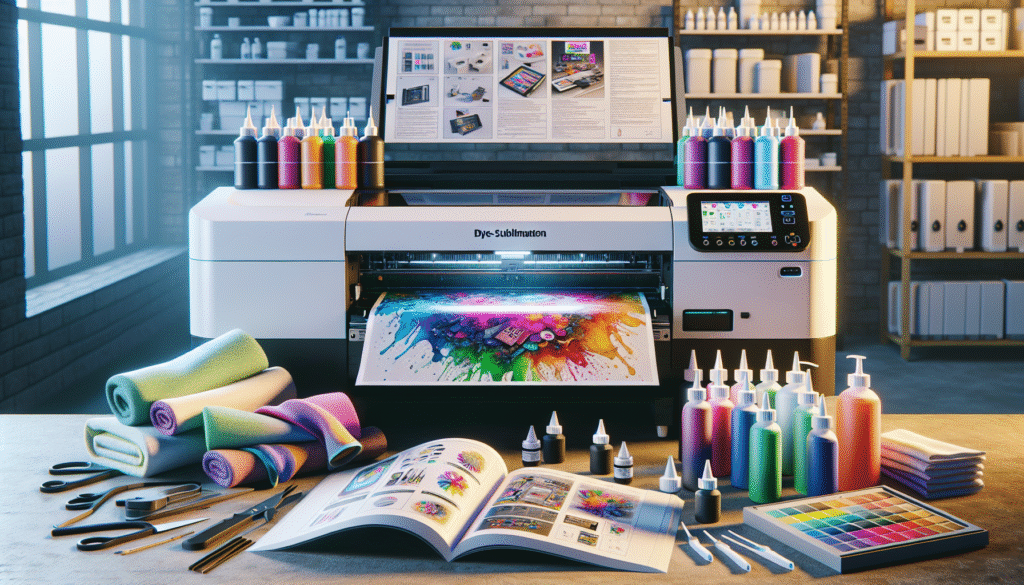

Have you ever found yourself wondering how we can ensure the longevity and performance of our dye-sublimation printer? If you’ve been on this invigorating journey with such technology, you aren’t a stranger to this query. We’re embarking on an exploration of sorts, a delightful expedition through the nuances of keeping our dye-sublimation printers in tip-top shape—like seasoned pros, of course. With a friendly touch, let’s unravel the mysteries of maintenance that could keep our equipment smiling and productive for as long as possible.

Understanding Your Dye-Sublimation Printer

Before we delve into maintenance, it is crucial to grasp what makes a dye-sublimation printer tick and why it is such a treasured gadget. These printers, which work by transferring dye onto materials such as fabric, plastic, or paper, offer vibrant and durable color printing. Unlike other printers, they create continuous tones without pixels, making them ideal for high-quality image reproduction.

The Mechanics Behind Dye-Sublimation

The process is fascinating—dye is heated, transforming from a solid to a gas without passing through a liquid state. This gas then permeates the printing surface, resulting in rich and vibrant prints that are resistant to fading. Understanding this process helps us appreciate why maintenance is vital; subtle changes can disrupt the transfer quality, affecting the final output.

The Importance of Routine Maintenance

Routine maintenance isn’t just something we do grudgingly. Think of it as nurturing a relationship. The better we care for our dye-sublimation printer, the more reliable and efficient it becomes. A well-maintained printer means fewer surprises, like unexpected downtime or unsightly print errors.

Avoiding Costly Repairs

One of the major advantages of regular maintenance is preventing expensive repairs down the line. By catching potential problems early, we save both money and time. This proactive approach means we’re more likely to avoid the heartbreak of dealing with extensive damage or having to replace parts unnecessarily.

Cleaning Your Dye-Sublimation Printer

Cleaning is the cornerstone of printer maintenance. It might not be glamorous, but it’s a necessity that can significantly extend the life of our equipment.

Cleaning Supplies Checklist

Let’s look at a list of cleaning supplies that can come in handy for the task. We wouldn’t want to be waist-deep in our cleaning adventure only to find we’re missing a vital tool!

| Cleaning Supplies | Purpose |

|---|---|

| Lint-free cloths | Dust and debris removal from surfaces |

| Isopropyl alcohol | Cleaning delicate parts without leaving residue |

| Compressed air | Dust removal from hard-to-reach areas |

| Rubber gloves | Protect hands during cleaning |

| Cotton swabs | Accessing tight spots |

Cleaning the Exterior

The exterior might not directly influence the print quality, but keeping it clean ensures the inner workings remain free from dust and grime. Wipe down the casing regularly with a damp lint-free cloth and keep the surrounding area tidy.

Delicate Interior Cleaning

Nurturing the inside of our printer is a delicate task. Gently clean the print heads and other components using isopropyl alcohol and cotton swabs. Being careful will prevent unintentional harm to the sensitive parts and ensure they function smoothly.

When to Seek Professional Help

Not all tasks are DIY friendly, and we must recognize when to call in the pros. For parts beyond our scope, professional service can offer detailed cleaning and spot issues we might miss. It’s all about knowing our limits to avoid accidents.

Regular Software Updates

Just as the hardware needs care, so does the software. Keeping our printer’s software updated ensures compatibility with various devices and improves functionality.

Updating Printer Drivers

Driver updates often introduce new features, enhanced security, and bug fixes. Check the manufacturer’s website periodically for new driver releases. This simple step can keep our printer running seamlessly.

Calibration Software

Many dye-sublimation printers come with calibration software designed to optimize color output and printing precision. Running these updates when they become available guarantees we’re always operating at maximum efficiency.

Managing Printer Consumables

Consumables like inks and paper play a crucial role in the printing process, and managing them properly can prevent numerous printing issues.

Ideal Storage Conditions

Store inks in a cool, dry place, away from direct sunlight. Exposure to heat or light can affect their quality, leading to subpar print results. Similarly, storing paper in a controlled environment prevents moisture absorption, which can lead to printer jams and uneven printing.

Keeping Track of Supply Levels

Keeping an eye on ink and paper levels helps avoid last-minute scrambles during critical print jobs. Promptly replacing and restocking prevents any interruptions due to depleted supplies.

Troubleshooting Common Issues

Understanding common issues and solutions not only helps us when problems arise but also builds our knowledge of what to look out for in the future.

Common Print Defects

Print defects are more common than we might hope. Banding, color mismatches, and missing lines are just a few examples. Familiarize yourself with these issues to quickly pinpoint the need for adjustments or cleaning.

Quick Fixes and Solutions

Here are some straightforward solutions to typical problems:

- Banding: Clean the print head and check ink levels.

- Color Mismatch: Calibrate the printer and adjust the color settings.

- Paper Jams: Make sure the paper is loaded correctly and isn’t curled or damp.

A little knowledge goes a long way in managing these hiccups before they evolve into major hiccup monsters.

Preparing for Long-Term Storage

Sometimes, we might need to store our printers, perhaps during off-peak seasons. Proper preparation is key to ensuring the printer is ready for action afterward.

Steps to Prepare Printer for Storage

- Empty Tanks: Remove all ink cartridges and clean the print heads.

- Cover the Printer: Use a dust cover to shield the printer from moisture and dust.

- Store in a Stable Environment: Ensure the storage area has consistent temperature and humidity levels.

Restarting After Storage

When bringing the printer back from storage, inspect for any dust build-up and perform a test print. This will identify any issues that might have developed during its slumber.

Best Practices for Optimal Performance

By now, we’re familiar with the nitty-gritty of maintenance, but let’s polish off our knowledge with some best practices to optimize performance and ensure our dye-sublimation printer stays in excellent condition.

Scheduled Maintenance Routine

Create a maintenance schedule that includes routine cleaning, software updates, and checking consumables. Consistency is our best friend in maintenance, helping us catch potential issues before they escalate.

Training and Knowledge Sharing

Sharing knowledge is empowering. By learning how to manage our equipment effectively, we expand our skill set and give ourselves the best chance of avoiding hiccups. If multiple people use the printer, ensure everyone knows the basic maintenance steps and the importance of handling the printer with care.

Staying Informed About Latest Trends

Technology doesn’t stand still, and neither should we! Stay informed about advancements in print technology and best practices. New strategies or tools may simplify maintenance or even improve print quality, keeping us a step ahead.

Conclusion

The quest to maintain our dye-sublimation printer like a pro is ongoing but undoubtedly rewarding. By nurturing our equipment with regular maintenance and informed care, we prolong its life and enhance the quality of our prints. Whether it’s understanding the nuances of cleaning, managing software updates, or preparing for seasonal lulls, each step we take reinforces our role as vigilant caretakers of technology. Together, we can ensure our dye-sublimation savvy lives on, print after beautiful print.