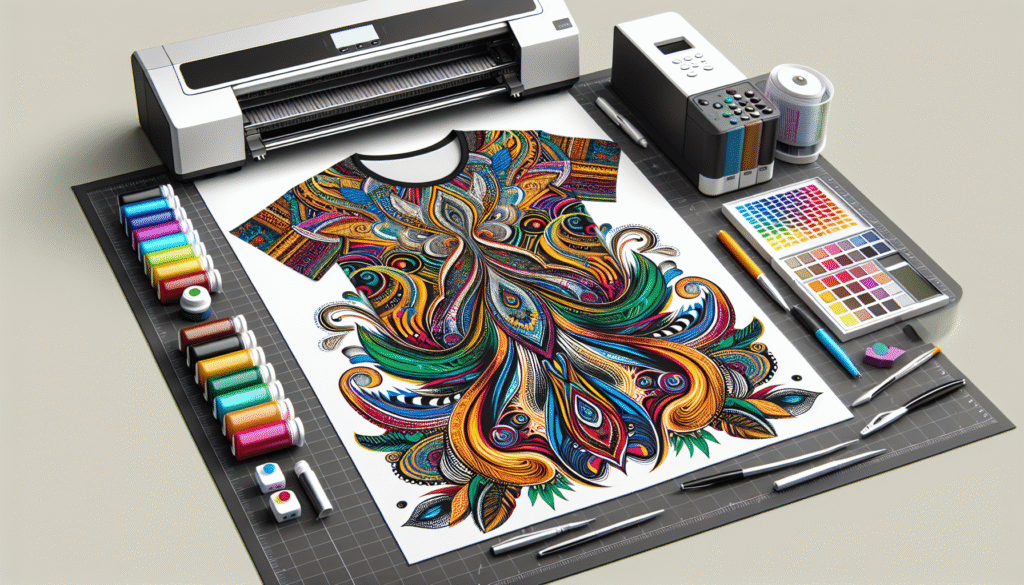

Have you ever found yourself staring at a plain white t-shirt, imagining the limitless design possibilities that could bring it to life? We often find ourselves pondering over the magic that turns a blank shirt into a work of art. This magic, as we discover, is sublimation printing. The world of apparel design has seen numerous innovations, but the crisp, vibrant prints achieved through sublimation stand apart. Today, let us journey together into the realm of the best sublimation printers that can transform your t-shirt ideas into reality.

Understanding Sublimation Printing

Before we jump into the specifics of the best printers, it’s essential to understand the basics of sublimation printing. Sublimation is a printing process where heat is used to transfer dye onto materials such as fabric. We appreciate this method because it allows for full-color designs across the entire surface of the material. Unlike traditional printing, the dye embeds itself into the fabric, resulting in a vivid, durable image that doesn’t peel or crack over time.

Why Choose Sublimation for T-Shirts?

T-shirts are a staple in our wardrobes, and getting the design right is crucial. Sublimation printing offers several benefits that make it ideal for apparel:

- Vibrant Colors and Detailed Prints: The process allows for bright colors and detailed images.

- Durability: Designs do not fade even after multiple washes.

- No Texture: The images are embedded into the fabric, so there is no additional texture.

- All-Over Prints: You can print all over the garment without any seams disrupting the design.

Choosing the Right Sublimation Printer

Selecting the right printer can feel overwhelming. Trust us, we’ve been there. With so many options available, it’s critical to understand your specific needs and the features each machine offers.

Key Features to Consider

When choosing a sublimation printer for t-shirt design, consider the following features:

- Print Width and Media Size: Ensure the printer can accommodate the size of prints you wish to create.

- Print Speed: Faster print speeds can increase productivity, especially if you’re printing in bulk.

- Resolution and Quality: Higher DPI (dots per inch) translates to better quality prints.

- Ink Type and Capacity: Look for high-capacity ink systems to reduce the frequency of refills.

- Software Compatibility: Make sure the printer is compatible with your design software.

Comparing Popular Models

To simplify the decision, we’ve put together a table comparing some of the leading sublimation printers available in the market today.

| Printer Model | Print Width | Resolution | Speed | Average Price |

|---|---|---|---|---|

| Epson SureColor F570 | 24 inches | 2400 x 1200 DPI | Fast | $2,500 |

| Sawgrass Virtuoso SG500 | 8.5 inches | 4880 x 1200 DPI | Medium | $549 |

| Epson EcoTank ET-15000 | 13 inches | 4800 x 1200 DPI | Moderate | $650 |

| Ricoh Ri 100 | 8.3 inches | 1200 x 1200 DPI | Slow | $1,799 |

| Canon ImagePROGRAF PRO-1000 | 17 inches | 2400 x 1200 DPI | Fast | $1,300 |

Detailed Look at Top Sublimation Printers

Let’s explore these models a bit further to see how they stack up individually.

Epson SureColor F570

The Epson SureColor F570 is one of our favorites for numerous reasons. Its wide-format capabilities are ideal for larger projects, and the impressive print resolution ensures high-quality designs. The ease-of-use and efficiency make it a strong contender for both beginners and seasoned professionals alike.

Sawgrass Virtuoso SG500

The Sawgrass Virtuoso SG500 is a staple for those just starting with sublimation printing. Its compact size is perfect for small spaces, and it provides excellent print quality with superb color consistency. We love how user-friendly it is, making it less intimidating for newcomers.

Epson EcoTank ET-15000

We know the importance of cost-efficiency in the printing business, and the Epson EcoTank ET-15000 provides just that. With its high-capacity ink tanks, it reduces the need for constant refills, making it economical in the long run. Its versatile printing size also adds to its appeal.

Ricoh Ri 100

While the Ricoh Ri 100 might be slower than its counterparts, it excels in simplicity and user-friendly design. It’s perfect for setting up a mini-printing station at home.

Canon ImagePROGRAF PRO-1000

For those of us who demand nothing but the best, the Canon ImagePROGRAF PRO-1000 offers exceptional quality. It’s suitable for artists and designers who want their prints to reflect the highest quality possible. The large print area also allows for bigger, more ambitious designs.

Advantages of Using Sublimation Printers in Apparel Design

It’s not just about technical specifications; understanding why sublimation printing thrives in apparel design is vital.

The Art of Vivid Designs

The tech behind sublimation ensures colors remain vibrant and fresh. Bright hues don’t just pop on the surface; they become part of the fabric, leaving wearers with a seamless, professional look that’s hard to achieve with other methods.

Durability: The Test of Time

Nothing frustrates us more than a gorgeous print that fades after a couple of washes. Sublimation prints boast incredible durability. They’re resistant to water, fading from sunlight, and general wear and tear, which means that designs stay looking new for far longer.

Simple Process for Complex Results

Despite the complexity and quality of the results, the process itself is straightforward. This accessibility allows even beginners to create professional-grade apparel. With the right equipment and materials, what we can achieve is indeed boundless.

Our Pro Tips for Successful Sublimation Printing

While the sublimation process can be easy to grasp, there are some tricks up our sleeve that ensure every print is a success.

Prepping Your Design

Make sure our design is suited for sublimation. High-resolution images (at least 300 DPI) work best, particularly for detailed or photo-quality designs. We also recommend leaving ample spacing within designs to avoid any overlap or cut-off areas during printing.

Choosing the Right Fabric

Polyester fabrics, blends with at least 65% polyester, and specially coated substrates are ideal for sublimation. While synthetic materials work beautifully, we should steer clear of cotton as it doesn’t bond well with sublimation inks.

Keeping Equipment in Check

Maintaining our printer and heat press is crucial. Regular cleaning and servicing ensure the machinery runs smoothly, preventing print errors. Also, performing nozzle checks frequently can help us avoid any surprises mid-project.

Using Heat Press Effectively

Achieving the perfect time, temperature, and pressure balance with our heat press can make or break the print outcome. Typical settings hover around 400°F for about 45-60 seconds, but we experimented and adjusted to find the sweet spot for our specific setup.

Challenges and Solutions in Sublimation Printing

Even with a stellar setup, challenges can arise. Here’s how we handle some common hurdles:

Ghosting

Ghosting happens when a design shifts during sublimation, causing blurry or shadowed prints. Investing in quality heat-resistant tape helps anchor designs in place, reducing movement during the pressing process.

Color Mismatch

Occasionally, final prints differ from software previews. Using an ICC profile tailored for sublimation can improve color accuracy, ensuring printed designs match what’s seen on the screen.

Printer Clogs

Printers, like us, can have a bad day. Regular printing, even if it’s just a simple color test, keeps the ink moving and prevents nozzle clogs—especially if the printer isn’t used daily.

Future-Proofing Your Sublimation Printing Setup

As technology advances, so should your printing setup. Keeping abreast of industry trends and staying open to new techniques and accessories will ensure we remain at the forefront of the apparel design industry.

Exploring New Materials

Keep an eye on emerging fabrics and transfer materials compatible with sublimation. Experimenting with advanced materials can set our designs apart and keep us ahead in the very competitive market.

Upgrading Equipment

While new equipment represents an investment, it can enhance quality and efficiency. Watch for deals and consider slowly integrating new machines that offer better specifications or additional capabilities.

Networking and Learning

Finally, staying connected with other designers and sublimation enthusiasts can provide valuable insights and support. Sharing experiences and learning from others’ trials and triumphs enriches our processes and expands our creative toolbox.

Conclusion

In our quest to create the perfect t-shirt design, finding the right sublimation printer becomes a pivotal step. The choices we make here influence the quality and longevity of our creations, bringing to life the vibrant, durable prints we’ve always dreamed of. By arming ourselves with knowledge about the best sublimation printers, their features, and the nuances of the printing process, we equip ourselves to make informed decisions. Whether we’re just starting or are seasoned professionals aiming to upgrade our setup, understanding the essentials empowers us to produce extraordinary apparel designs.