Have you ever stopped to think about the incredible things we can create using 3D printers these days? I mean, it’s not just about tiny figurines or spare parts anymore. We’re talking about massive structures, custom furniture, and even houses! As someone who’s been fascinated by how technology shapes our lives, I’ve noticed that large format 3D printing seems to be getting an upgrade, making these big builds more accessible to everyone. It’s as if the tech is waving a friendly hand and saying, “Come on in, the print dimensions are fine!”

A Brief Look Back: The Evolution of 3D Printing

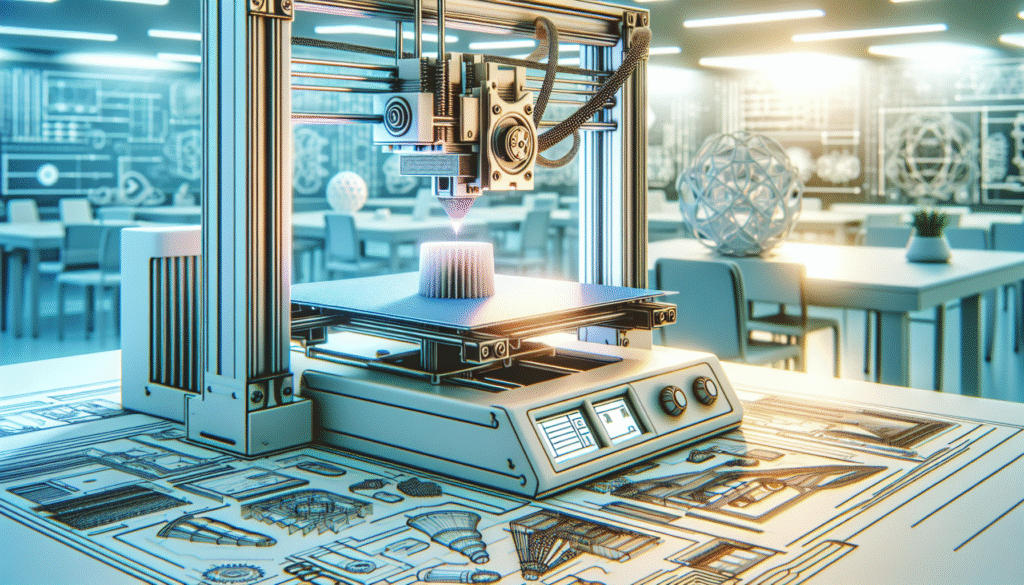

Before we dive into the big stuff, let’s take a nostalgic stroll down memory lane and see how far 3D printing has come. Initially, it was a niche technology used mainly by industrial designers and engineers for prototyping. Imagine a small, exclusive club where everyone is discussing layer resolutions and nozzle diameters over coffee. But as time marched on, the technology became more user-friendly and affordable.

Milestones in 3D Printing History

To put things into perspective, I’ve jotted down some key moments.

| Year | Milestone |

|---|---|

| 1986 | The first patent for stereolithography filed |

| 1992 | The first stereolithographic apparatus built |

| 2009 | Expiration of key patents, opening the doors for consumer-grade printers |

| 2013 | NASA 3D prints a rocket engine component |

| 2020 | COVID-19 spurs innovations in 3D printing PPE |

Now, we’re at a point where nearly anyone can join the conversation, and the focus has shifted from small gears and gizmos to large, sweeping structures that can change industries.

What is Large Format 3D Printing?

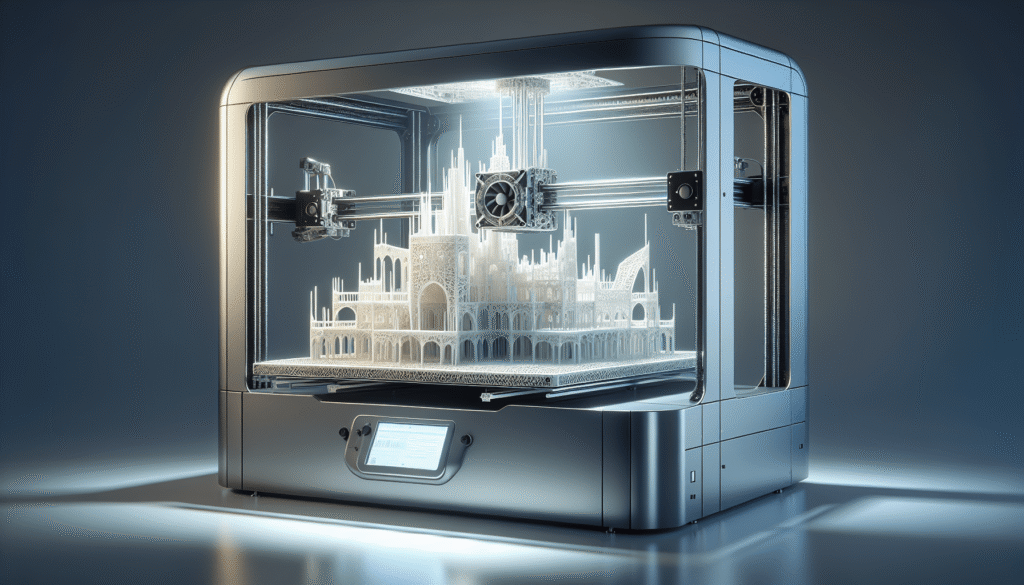

When we speak of large format 3D printing, we’re not just increasing the scale by a few centimeters. We are talking about printers that have bed sizes measured in meters, and capabilities to create objects that rival those dinosaur skeletons in museum halls. It’s not just a big step; it’s a giant leap forward in capability and imagination.

Benefits of Large Format 3D Printing

Creating large objects with 3D printing technology offers several intriguing advantages:

- Scalability: Larger build volumes make it possible to print big objects in one go rather than assembling smaller parts.

- Innovation: Opens avenues for designing complex structures that are often impossible with traditional methods.

- Cost-Effectiveness: Reduces labor and material waste by creating objects directly from a digital model.

Having detailed these benefits, let’s now consider how this trend is becoming increasingly available to different sectors—and not just the elite tech wizards in lab coats.

Industries Embracing Large Format 3D Printing

Shall we take a tour of the industries that are welcoming large format 3D printing with open arms? Spoiler alert: it’s not just about making quirky, oversized gadgets for tech expos.

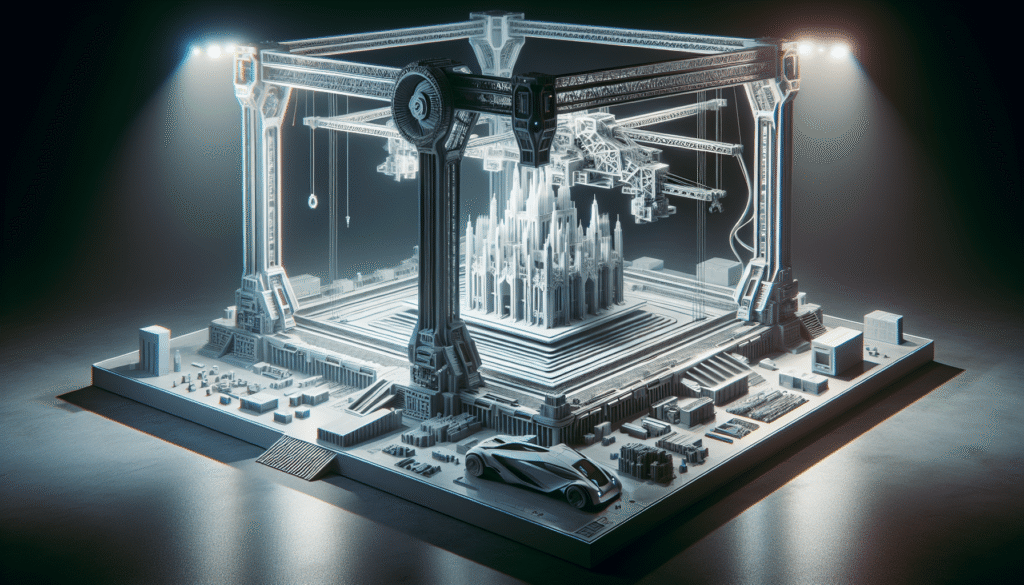

Architecture and Construction

You might think of architects sitting at draft tables, but these desks are now becoming digital screens, complemented by the hum of 3D printers. From creating customized homes to intricate bridges, these technologies are being woven into the very fabric of the building process.

Automotive and Aerospace

The marriage between 3D printing and vehicle manufacturing is one for the ages. Large format printing allows for the production of entire car bodies and significant aircraft components in ways and efficiencies never before thought possible. Talk about taking a Sunday spin in a completely bespoke vehicle.

Art and Design

The art world’s relationship with 3D printing has always been like watching someone fall in love—a bit shocking but ultimately beautiful. Artists now wield large format printers to craft monumental sculptures, each a testament to what happens when creativity meets technology.

Film and Entertainment

Ever marvel at those intricate movie sets that look like you could just step into another world? Many such marvels are now being brought to life with the help of large format 3D printing, revolutionizing set design and prop production.

Technological Advancements Making This Possible

So, how did we get here? How are these magnificent, room-sized printers rolling out seamlessly constructed marvels? It feels like we’ve unearthed a secret technology, a mythical tool from a future world that’s been working all along while we were busy decoding gadgets the size of our palms.

Materials

The advances in materials have been nothing short of revolutionary. Where printing was once limited to plastics, we now have metals, concrete, and composite materials making their way into the 3D printing lexicon. Remember when choosing a salad dressing was the hardest choice of the day? Now, it’s about selecting the exact composite for load-bearing architecture.

Software

The sheer intelligence backing 3D printing software today is astounding. Easier interfaces, richer libraries, and smarter error-checking algorithms make the process less akin to solving a Rubik’s cube and more like a free-flowing river of creativity.

Hardware

Printers themselves have made striking advances. They’re faster, more precise, and capable of working with a wider range of materials. If they were actors, this stage-right entrance would surely earn a solid standing ovation.

Overcoming Challenges in Large Format 3D Printing

No technology comes without its set of challenges. But what’s a hero’s story without a few hurdles, right? Whether it’s dealing with the skepticism of adopting new methods or wrestling with logistical puzzles, there are challenges to be tackled.

Efficiency and Speed

One of the significant hurdles is the speed of production. Although large format printing is more cost-effective in some ways, it still lacks the pace at which traditional manufacturing operates. It’s a bit like watching a timeless old movie that runs a tad slower than current flicks—but infinitely more rewarding.

Cost

While the cost of 3D printing technology is decreasing, the initial investment for large format printers is still substantial. This places some limitations on who can engage fully with the technology, often sidelining smaller enterprises, like a party you wish you could join but didn’t receive an invite for.

Quality Assurance

Ensuring consistent quality on such a large scale can be like balancing on a tightrope while juggling. Flaws need to be caught early to avoid costly errors, requiring meticulous attention to detail.

Environmental Impact

As more industries pivot towards large format 3D printing, questions about sustainability arise. Balancing this promising technology with eco-friendly practices is a hurdle that needs overcoming to keep those green-minded folks from wagging their fingers.

The Path Forward: Making Big Builds More Accessible

So, how do we make these exciting trends more accessible to the masses? The future of large format 3D printing is not locked behind an inaccessible door but rather unfolding each day in labs and workshops worldwide.

Reducing Costs

What makes my heart sing is seeing the downward trend in costs for both printers and materials. This means more creativity unfurling from previously hidden corners. Think less exorbitant price tags and more people-enabled creativity.

Education and Training

Education plays a big role here. If more people are skilled in using 3D printing technologies, the barriers to entry will lower significantly. Schools and training programs focusing on these new technologies prepare generations to step confidently into this expansive digital era.

Collaborative Efforts

Industry, education, and government collaborations can create an ecosystem where large format 3D printing thrives not just in pockets but as a fabric of society. It’s a community effort, much like potlucks where each participant has something valuable to add.

Future Predictions: What Lies Ahead?

As we gaze into the crystal ball, what does the future hold for large format 3D printing? It’s as though we’re on an exhilarating marathon, and each year brings us a bit closer to the unimaginable.

Mainstream Integration

I see a future where the boundary between design and manufacturing blurs, where ideas originate from a morning thought over coffee and manifest by dusk. The ease and reach of 3D printing make it a staple in industries once light-years away.

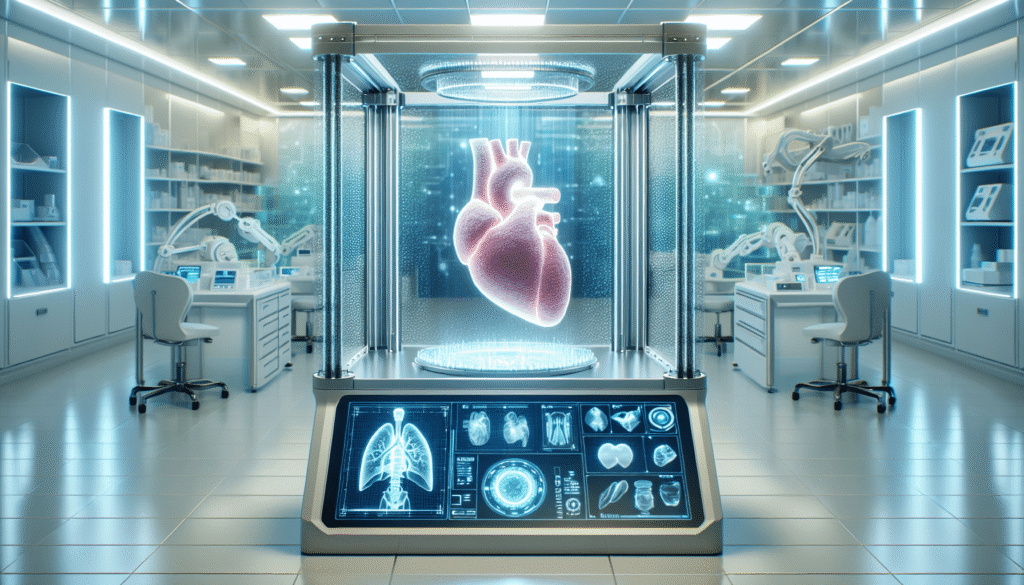

New Industries Adopting the Technology

Expect new sectors to dip their toes into the 3D sea. Whether it’s new-age fashion houses crafting unique apparel or medical facilities printing prosthetics on demand, the field is wide open.

Proliferation of Open-Source Models

With enough individuals contributing to open-source designs, the pool of shared knowledge will only expand. Imagine the open-source model as a library where each book contains the potential to alter reality.

Conclusion: A World of Possibilities

The sphere of large format 3D printing brims with potential, innovation, and an unstoppable momentum. It’s not just about larger build volumes or new materials, but how these developments are democratizing creation itself. This technology is acting as a baton, handed to anyone poised to sculpt the future. And it’s about time we all stopped and marveled at what our combined human creativity can forge when limitations fade away. Wouldn’t you agree?