Have you ever wondered what our future will look like if we keep up with our current levels of consumption and waste? Well, I’ve been pondering the same thing, especially when it comes to the ever-evolving realm of 3D printing. As we edge closer to 2025, the drive toward sustainability in 3D printing becomes increasingly vital. Drawing from my own curiosity, I’ve embarked on a journey to uncover what’s happening with sustainable 3D printing materials. Stick around to hear about the eco-friendly innovations that are leading the charge.

The Rise of 3D Printing

A good place to start is understanding why 3D printing has captured our attention in the first place. 3D printing, or additive manufacturing, has rapidly grown in popularity due to its ability to produce complex designs with relative ease. It adds layer upon layer, building products from the ground up. This capability not only allows for customizability but minimizes waste compared to traditional manufacturing methods.

Why Opt for 3D Printing?

In traditional manufacturing, subtractive processes often remove material, meaning excess and waste. With 3D printing, there’s an almost artistic edge to the process—think of it as sculpting an object one thin layer at a time. This efficiency alone makes it a favorite choice across industries, from automotive to healthcare. But for it to be a truly sustainable choice, the materials used must also be eco-friendly. That’s the piece of the puzzle we’ll be focusing on.

What Makes a Material Sustainable?

Now you might be asking, “What exactly makes a material sustainable?” That’s a fair question. It’s all about the lifecycle of the material—right from sourcing to disposal. Sustainable materials often come from renewable resources, have lower carbon footprints, and don’t negatively impact the environment after their life cycle ends.

Criteria for Sustainable Materials

- Source of Materials: Ideally, materials should be sourced responsibly, with environmental impacts minimized from the start.

- Energy Consumption: The material should require minimal energy throughout its processing.

- End-of-Life Impact: The material should be recyclable or biodegradable.

- Toxicity: Non-toxic materials are preferable to prevent harm to both the environment and human health.

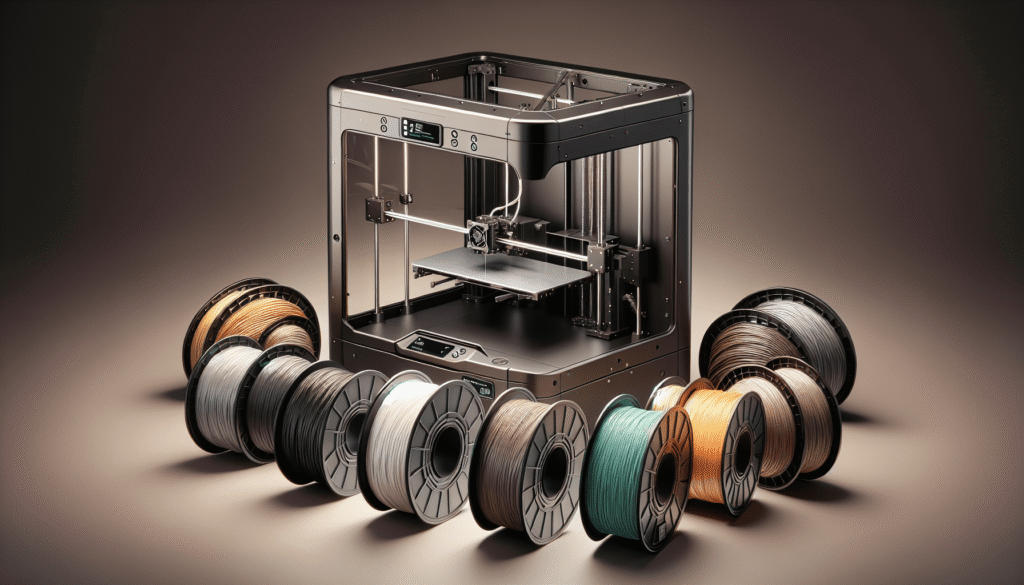

Sustainable Material Innovations in 3D Printing

In the face of growing environmental concerns, many industries are embracing change—and 3D printing is no exception. Thinking beyond petroleum-based plastics, there’s a slew of sustainable materials that are reshaping the industry.

Bioplastics

Picture plastics, but friendlier. I’m talking about polylactic acid (PLA) derived from cornstarch. PLA is biodegradable, compostable, and fits snugly into the pre-existing 3D printing framework. It easily degrades into harmless natural compounds, merging back with the environment. Isn’t it fascinating to imagine that a cornfield might one day supply the raw materials for your next 3D-printed gadget?

Recycled Plastics

Rather than seeing waste as the end of the road, recycled plastics offer a fresh start. Materials like recycled PET (Polyethylene Terephthalate) essentially breathe new life into discarded bottles and containers. It’s a small pivot with a big impact, turning trash into treasure and drastically cutting the demand for virgin plastic.

Bio-inks

Now, this is where things get a bit sci-fi. Bio-inks are used primarily for bioprinting—creating structures similar to living tissues. Made from natural polymers, bio-inks herald exciting possibilities for the medical field, promising personalized healthcare solutions and genuine tissue regeneration. Imagine a world where organs can be printed on demand for transplants.

Hemp and Other Natural Fibers

The use of hemp and other fibers, like bamboo, revolutionizes the field—showcasing not just sustainability but enhanced material properties. They help fortify biodegradable plastics, adding strength without compromising the environment. Natural fibers like hemp absorb CO2 while growing, sequestering carbon as part of their lifecycle.

Case Studies: Innovations Leading to 2025

We can talk theory all day, but nothing drives the point home quite like a tangible example. Let’s zoom into the real-world trailblazers who are setting the course for what lies ahead.

Example 1: The Automotive Industry

Several automotive companies, recognizing the need for change, are turning to 3D printing using lightweight materials. Imagine a world where car parts are printed bespoke, reducing waste and energy costs. Giants like BMW and Ford are making strides here, showing us what a sustainable vehicle manufacturing transformation could entail.

Example 2: Sustainable Fashion

In the world of fashion, sustainability might just be the new black. Designers are testing materials like algae-derived polymers and recycled filament to craft innovative, eco-friendly apparel. Who would’ve thought fashion and sustainability could waltz so gracefully?

Example 3: Advancements in Healthcare

Returning to bio-inks, I’m awed by companies leveraging 3D printing for personalized medicine. Imagine being custom-prescribed medication designed to fit your genetic makeup or bioprinted organs available for transplants. The convergence of customization, health, and sustainability is not just science fiction—it’s a reality within reach.

Challenges on the Path to Sustainability

Yet, it’s not all sunshine and rainbows. There are notable roadblocks slowing our progress toward sustainable materials in 3D printing.

Production Costs

As with any cutting-edge technology, the cost can be inhibitive. Sustainable materials often require more refined processes, which can increase the overall cost. Over time, economies of scale and technological advancements might ease this burden, but cost remains a significant hurdle today.

Scalability

If we’re to transform global industries, scalable solutions are imperative. While the thought of a sustainable future is an alluring prospect, the truth is, not all eco-friendly materials can yet be produced at the required scales.

Material Properties

Balancing sustainability with practicality can be a daunting task. Some sustainable materials may lack the mechanical properties needed for certain uses, limiting their applicability. Ongoing research focuses on addressing these gaps, but the balance is delicate.

Looking Ahead: The Future of Sustainable 3D Printing

If there’s one thing I’ve learned from observing the sustainable 3D printing movement, it’s that optimism drives innovation. We’ve planted the seeds for a greener future, and anticipation surrounds watching them grow.

The Role of Policy and Advocacy

As rewarding as grassroots innovations can be, significant advances often need the push of policy changes. Governments and regulatory bodies have a crucial role in encouraging the adoption of sustainable practices. Incentives for research and development, alongside policies favoring the use of eco-friendly materials, could accelerate change.

Academic and Research Contributions

Universities and research institutions are constantly driving exploration across various themes. From discovering novel materials to improving existing processes, academia plays a pivotal role in sustaining momentum. Collaborative innovation means pooling resources and knowledge, ultimately yielding breakthroughs to fuel further development.

Taking Individual Steps

Finally, the role of individuals cannot be underestimated. Supporting companies that prioritize sustainability and opting for eco-friendly products shape demand. It turns out one small choice, multiplied across millions, could subtly steer us toward the sustainable future we seek.

Table: Comparison of Common Sustainable 3D Printing Materials

| Material | Source | Biodegradability | Uses | Challenges |

|---|---|---|---|---|

| PLA | Cornstarch | Yes | Consumer goods, prototypes | Brittle, lower heat resistance |

| Recycled PET | Recycled plastics | Limited | Filaments, textiles | Limited recycling loops |

| Bio-inks | Natural polymers | Yes | Medical, bioprinting | Complex to produce |

| Hemp fibers | Hemp plants | Yes | Composites, construction materials | Limited availability |

| Algae polymers | Algae | Yes | Textiles, packaging | Cultivation challenges |

In conclusion, delving into sustainable 3D printing materials reminds me that change starts with curiosity, which fuels progress. As we look ahead to 2025, these innovations promise an era of thoughtful technology woven seamlessly with environmental consciousness. It’s a journey I’m thrilled to witness, one curious layer at a time.