Do you ever wonder how far we’ve come from the days of dot matrix printers and floral wallpaper? I do, and in this tale of transformation, we’re venturing into the thrilling world of ultra-fast 3D printing technologies. Once the stuff of science fiction, 3D printing is now tearing down the gates of conventional production with the gusto of a bulldozer at a tea party.

A Quick Primer: What is 3D Printing?

To set the scene, let’s start with the basics. 3D printing, technically known as additive manufacturing, is the process of creating three-dimensional objects by layering materials based on a digital model. It’s like making a sandwich, but less edible and much more intricate. Whether it’s plastic, metal, or some other space-age material, these layers coalesce into an item as if conjured by magic.

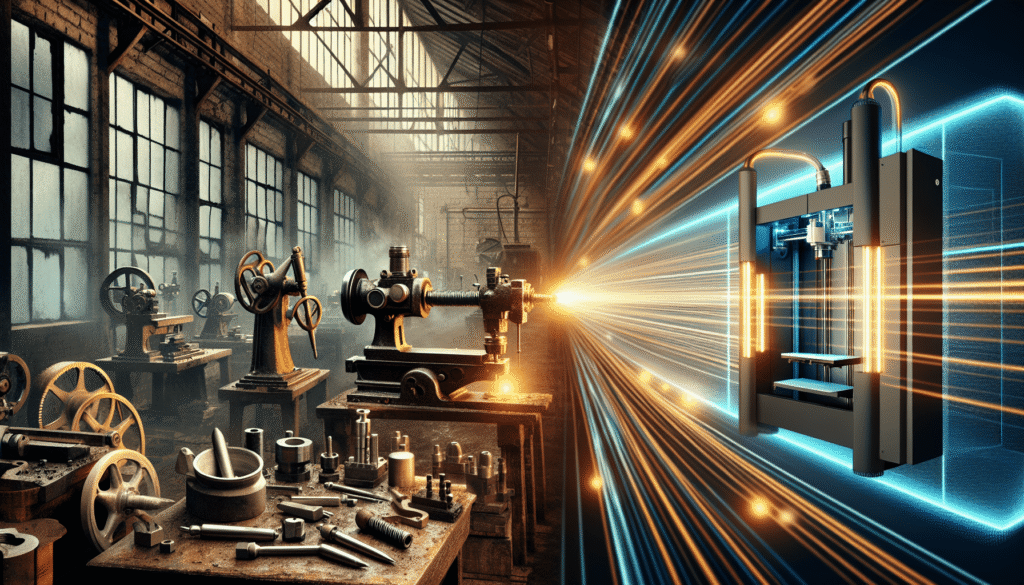

The Evolutionary Journey

3D printing is not a new kid on the block. Its beginnings whisper tales from the 1980s, promising wonders that seemed too futuristic for the average Jane or John. Early versions trundled along at the pace of a tired tortoise, but technological advancements have propelled them into the fast lane, making high-speed production not just possible but commonplace.

The Need for Speed: Why Fast Printing Matters

Think about those tense moments when you’re waiting for toast in the morning—seemingly endless. Now imagine that scale of impatience applied to industrial production. Speed in 3D printing isn’t just a convenience; it’s a revolution.

Benefits of Speedy Printing

-

Reduced Production Time: The most obvious perk is a drastic cut in the time taken to manufacture goods. Products that once took days or weeks to make can now be ready in hours.

-

Cost Efficiency: Faster print times mean less labor and reduced overhead costs. Time is money, after all.

-

Increased Flexibility: With faster production times, businesses can swiftly adapt to changes in demand or design tweaks, offering personal customization to customers without lengthy delays.

-

Environmentally Friendly: For the green hearts among us, quicker printing processes also tend to minimize waste, consuming less energy in the production process.

Meet the Game-Changers: Ultra-Fast 3D Printing Technologies

With the scene sufficiently set, let’s introduce the stars of the show: the high-speed 3D printing technologies that are causing traditional manufacturing norms to flip their hats in utter astonishment.

Continuous Liquid Interface Production (CLIP)

Instead of building structures layer by layer, CLIP uses a pool of liquid resin and a meticulous dance of light and oxygen to craft objects continuously, like sculpting an ice block with a heat lamp. This method dramatically increases speed and surface quality, offering a finish as smooth as a bedtime story.

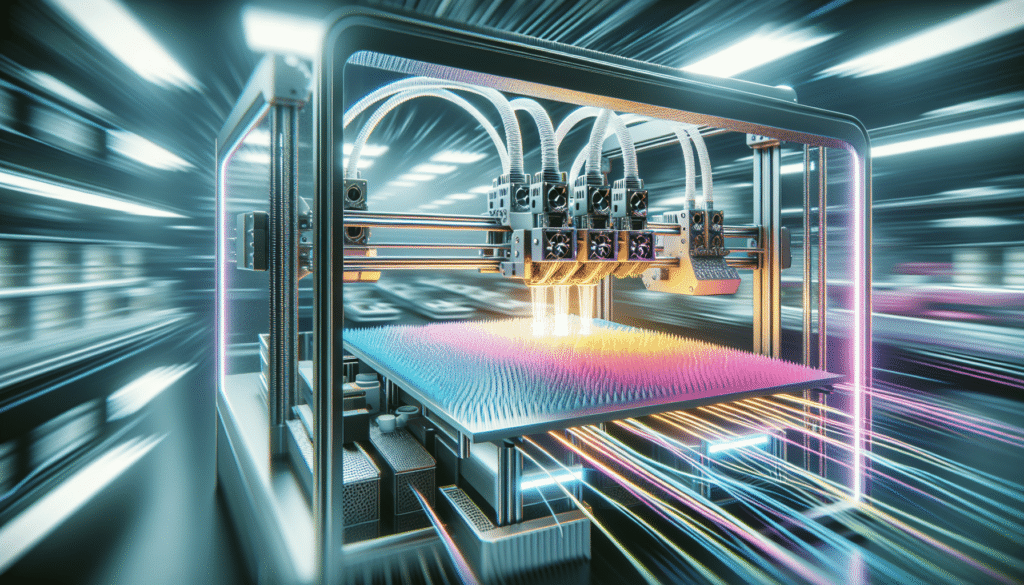

Multi Jet Fusion (MJF)

MJF is akin to a street magician that wows you with its quick-sleight of hand. It involves laying down fine layers of powder, which are then fused together using fusing agents and detailing agents. Once exposed to heat, these powders transform into solid objects. Think of it as a high-speed gritty paint-by-numbers activity, except the end result is more functional than fridge art.

High-Speed Sintering (HSS)

Closely related to MJF, HSS involves the use of infrared lamps to sinter— a fancy word for fuse—powder particles together. This method stands out for its capability to handle high production volumes without compromising detail or finish.

Speedy Sheet Lamination

For those who think layer by layer is so yesterday, sheet lamination takes thin layers of material and binds them together using adhesive and pressure. It’s a papercraft of industrial proportions, offering rapid production speeds for larger parts with mixed materials.

The Industries and Their Stories: Transformations Through Speed

Speedy 3D printing technologies are not just twiddling their thumbs in solitude; they’re stirring up revolutions across various industries.

Automotive

The automotive sector is letting loose to the tune of accelerated part production and rapid prototyping. From personalizing car interiors to designing complex engine components, faster printing helps meet demanding timelines and innovative designs without breaking a sweat.

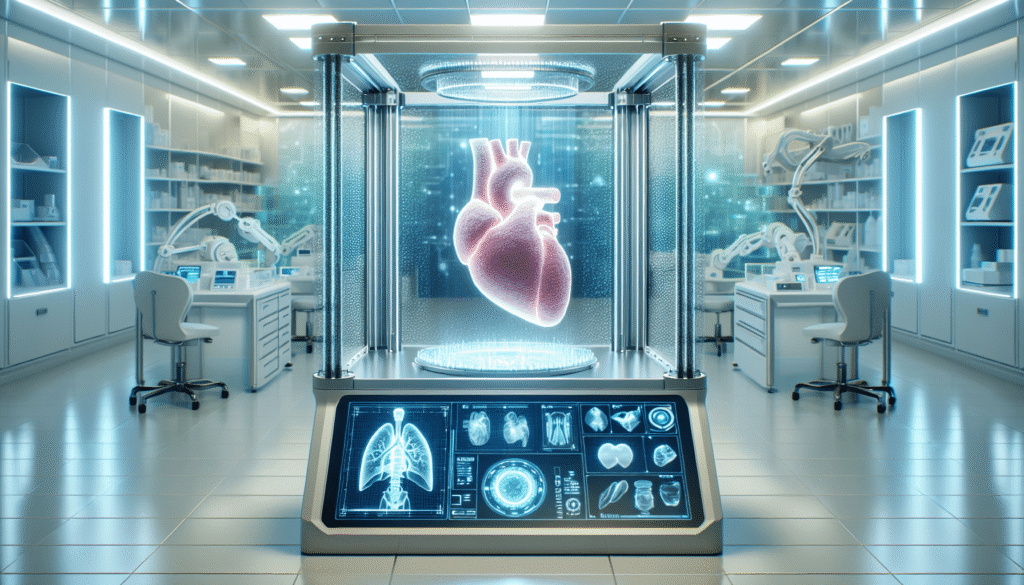

Healthcare

Imagine a future where bespoke medical devices are printed at speeds fast enough to match patient needs. Custom prosthetics and even bio-printed tissues are not mere dreams anymore. Speedy 3D printing is easing the aches of production logjams, offering solutions as rapid and specialized as a tailor-made suit.

Aerospace

Space may be infinite, but time isn’t. The aerospace industry is taking full advantage of rapid 3D printing to produce parts that are not only lightweight and complex but also assembled in record time. The sky isn’t the limit; it’s just the beginning.

Consumer Goods

From dazzling jewelry to the latest gadgets, the consumer market thrives on variety and novelty. Speedy printing enables quick market testing and customization, delivering products as fast as the public can dream them up.

Challenges on the Fast Lane: Overcoming Speed Bumps

You didn’t think everything would go off without a hitch, did you? Like a car with overly enthusiastic suspension, rapid 3D printing brings its own set of challenges.

Quality Control

Producing at high speeds doesn’t always equate to superior quality. Maintaining precision and consistency is a constant battle, balancing the desire for speed with the requirement for quality.

Material Limitations

While the technology races ahead, available materials sometimes lag behind, with limited options that can handle rapid production times without losing integrity or finishing.

Initial Investment

It can cost a king’s ransom (or rather, a company’s budget) to invest in the newest, bleeding-edge machinery. For smaller enterprises, these initial costs can be prohibitive.

Skill Requirements

As much as we’d like these devices to come with an “Easy” button, operating them requires a unique skill set. The workforce must adapt and learn, scaling the learning curve swiftly.

The Future Unfolds: What Lies Ahead?

As my proverbial hat tilts to the horizon, let’s peer into what may come in the world of ultra-fast 3D printing. The evolution is unlikely to stop or even slow down. Instead, innovations point towards even faster processes, smarter systems, and wider material availability.

Intelligent Automation

Automation of the entire production process ensures that human errors are minimized. Picture a factory where printers communicate with each other and adjust parameters in real-time to optimize each task, reducing wastage and errors.

Expanded Material Range

The horizon promises the development of new materials suitable for high-speed printing. From biodegradable plastics to stronger alloys, the potential product range will expand, leading to innovations across sectors.

Integration with AI

Artificial intelligence is stepping in to analyze conditions and predict failures before they occur, ensuring seamless operation. Think of it as having your personal oracle, guiding production with foresight.

Conclusion

In a world that demands immediacy, the speed revolution in 3D printing is more than just an advancement; it’s a transformation of how we will view production forever. As we embrace these fast-paced methodologies, industries across the globe will find themselves not just keeping pace, but setting it. As I pen down these thoughts, I can’t help but imagine the endless possibilities and scenarios, where productivity feels like the rush of wind on a perfect driving day – a rush that’s set to continue for miles and miles on the road ahead.