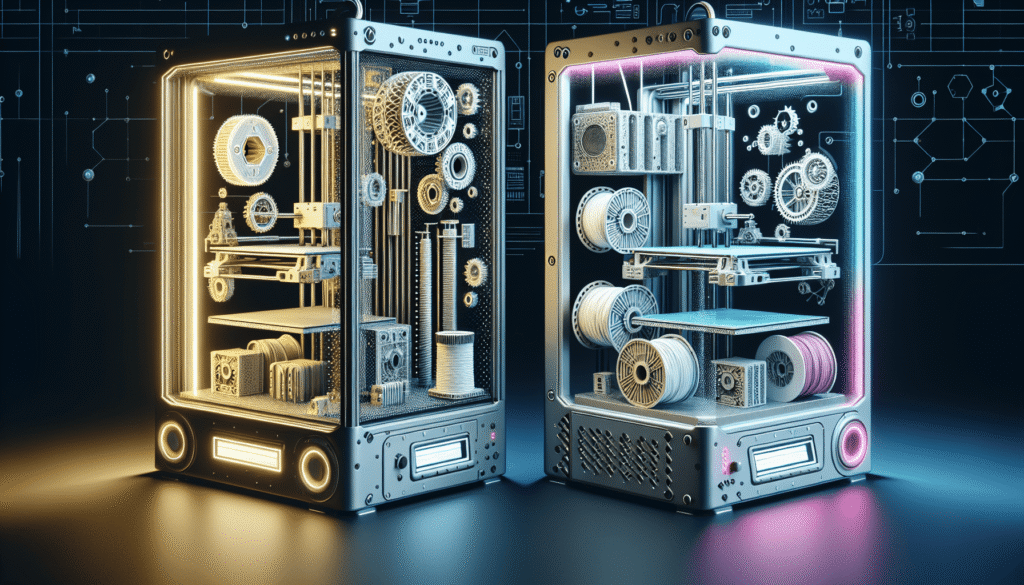

Isn’t it fascinating how far 3D printing technology has come, and can you imagine what the world of 3D printing might look like by 2025? The clash between Resin and FDM (Fused Deposition Modeling) 3D printing methods is indeed an exciting narrative that’s reshaping the industry. Let’s take a closer look at how these two technologies compare and what might lie ahead for both.

The Basics of 3D Printing: Understanding Resin and FDM

Before diving into the future landscape, it’s critical to grasp the fundamental differences between Resin and FDM 3D printing. While both technologies are pillars of the 3D printing realm, they have distinct characteristics and applications.

What is Resin 3D Printing?

Resin 3D printing, often referred to as SLA (Stereolithography) or DLP (Digital Light Processing), utilizes liquid photopolymers that are cured using UV light. This process is particularly renowned for delivering high-resolution results, capturing fine details with precision. It’s like the artist’s brush in the 3D printing world, able to craft delicate and intricate designs.

What is FDM 3D Printing?

On the other hand, FDM 3D printing involves layering thermoplastic materials, unwinding filament through a heated nozzle that traces the object layer by layer. It’s beloved for its versatility and affordability, akin to the jack-of-all-trades in 3D printing. It’s not about the minutiae or minute details but rather the broader strokes of creation that count.

The Technological Developments: 2025 Outlook

As we inch closer to 2025, both Resin and FDM technologies have undergone significant advancements. The question now is not which is superior but how each has evolved to meet differing needs.

Advancements in Resin 3D Printing

Resin printing in 2025 has made leaps in the speed of curing times. With advancements in light source technology, curing each layer happens faster than ever, drastically reducing print times. In addition, newer resin formulations now offer enhanced mechanical properties, broadening the range of functional applications. Imagine a world where you’re printing car parts one minute and designer jewelry the next—all using the same advanced resin technology.

Advancements in FDM 3D Printing

FDM technology has also seen its share of evolution, primarily through the development of multi-material and multi-color capabilities. The printers now possess advanced sensors and automated features that make the calibration and support settings effortless, leading to fewer mechanical failures. It’s a bit like swapping from a stick shift to a fully automatic car—not everyone can appreciate the manual toil when there’s a seamless option available.

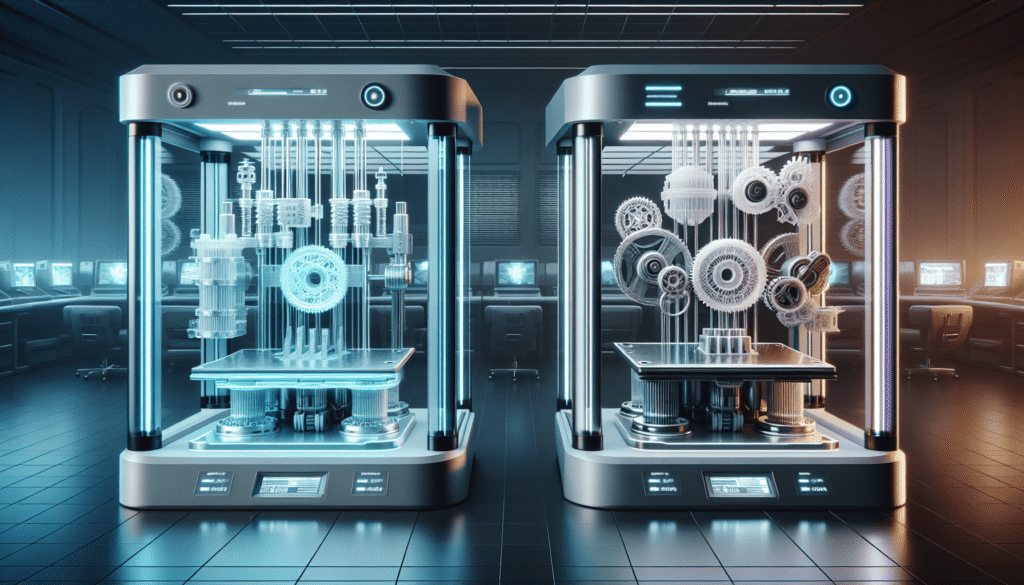

Comparing the Two Technologies

So, how do Resin and FDM fare against each other in 2025? Let’s break it down using a simple table to highlight key differences and similarities, which is always a good way to sort out the facts:

| Aspect | Resin 3D Printing | FDM 3D Printing |

|---|---|---|

| Resolution | High precision and details | Lower resolution |

| Material Costs | Generally higher | Lower cost, more options |

| Speed | Slower, but improving | Faster for large projects |

| Durable Parts | Yes, with new resins | High durability with certain filaments |

| Print Size | Limited by build volume | Can handle larger prints |

| Ease of Use | More complex setup initially | Generally easier to start with |

Battle for the Future: Deciding Factors

As these technologies develop, several crucial factors determine their suitability for future applications. From prototyping to mass production, each has unique strengths that provide users with distinct advantages.

Business and Industrial Applications

For industries focusing on minute details, such as jewelry or dental prosthetics, resin printers offer unmatched detail and finish. FDM, however, remains the workhorse for manufacturing prototypes and functional parts at a cheaper rate.

Environmental Considerations

Sustainability in 3D printing is a growing concern, with newer technologies addressing these issues head-on. Resin printing may face more scrutiny due to potential environmental hazards linked with leftover liquid resins. FDM, using biodegradable PLA, enjoys a slight edge in being eco-friendly, even though it depends on the chosen material.

The Reshaping Effect: Impact on Industries

How are these technologies playing out in industries? Here are a few examples of where Resin and FDM are making waves:

- Healthcare: Resin printing facilitates detailed work like dental impressions and surgical models, while FDM is used for custom prosthetics.

- Aerospace: FDM is favored for creating lightweight components essential in aeronautical engineering.

- Consumer Goods: Both technologies are used to create everything from fashion items to furniture prototypes, giving designers room to experiment with forms and functions.

The Shift in Consumer and Hobby Markets

In personal and hobbyist spaces, folks are developing a taste for Resin printing because of the quality it brings to miniatures and figurines. With prices becoming more accessible, FDM faces stiff competition here as enthusiasts balance quality against practicality.

Looking Forward: What Will Be the Game-Changer?

As we move toward 2025, both Resin and FDM printing are contenders in their ways, but neither is likely to completely overtake the other. Instead, the goal is specialization and advancement catered to specific applications that fit the ever-diverse needs of tomorrow’s creators.

Hybrid Approaches

The rise of hybrid printers that combine the capabilities of both FDM and resin technologies could offer the best of both worlds. Imagine a scenario where you get the material flexibility of FDM combined with the detailed finesse of Resin, without swapping machines—this could indeed be revolutionary.

Conclusion: Making Sense of a Dynamic Battle

Navigating the complexities of 3D printing technologies is as enthralling as it is complex. In this ever-evolving battle between Resin and FDM, the ultimate winner doesn’t lie in a clear dichotomy. Instead, the trail blazes with continued innovation shaping the landscape in tandem. As consumers or industry professionals, the key is understanding what each technology provides and making informed choices based on the specific requirements at hand.

This technology battle reshaping the industry is more than a competition; it’s a dance of technical marvels, each improving our capacity to create in ways previously reserved for the realm of art and imagination. Whether you’re a maker exploring new possibilities, a company aiming to innovate, or simply an enthusiast watching from the front row—the journey is as exciting as the summit.