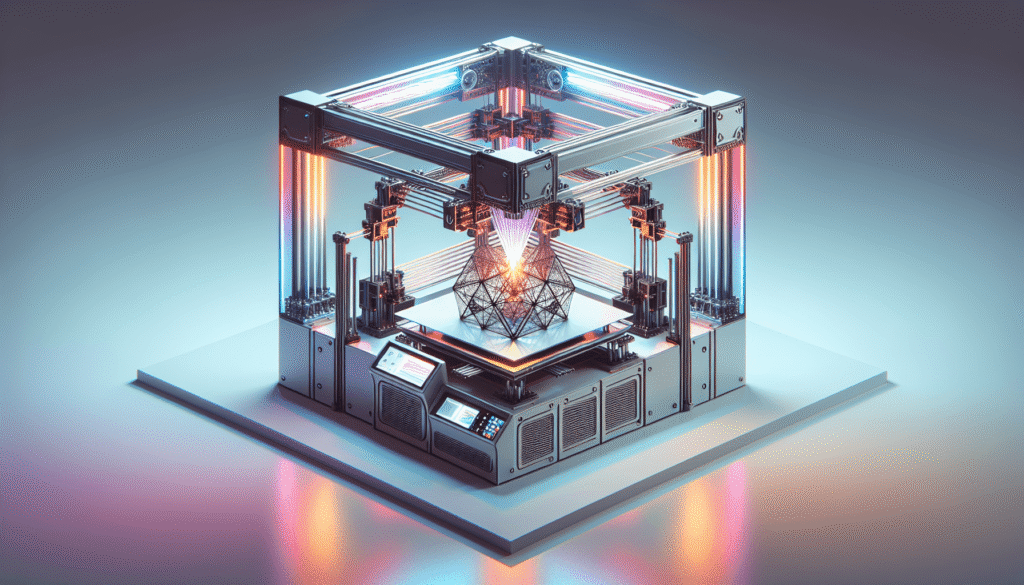

Could you ever imagine a world where manufacturing is dominated not by traditional assembly lines but by the whir of 3D printers? As we look toward 2025, we’re on the brink of a revolution that promises to reshape industries, economies, and our very way of life. The 3D printing industry, also known as additive manufacturing, is hitting its stride, and there are several trends that stand poised to redefine its landscape.

The Evolution and Potential of 3D Printing

Before we dive into the dozen trends that will steer the industry’s future, it might be worth reminiscing a bit about how far 3D printing has come. Originally, it was a niche technology marred by its limitations in material and scale. Fast forward to today, and it is no longer just a prototyping tool but a force that can construct anything from medical implants to entire houses.

A Brief Look Back

Let’s step back a couple of decades—3D printing, back then, seemed like a novelty act in the tech circus. The skeptics scoffed and dismissed it as a fad, but the innovators saw potential. The scale and precision have vastly improved, the costs have plummeted, and now it seems like everything under the sun can be printed.

Why 2025 Matters

The magic year, 2025, is expected to be pivotal. By then, 3D printing will likely transition from being an impressive technological feat to a cornerstone of industrial production. This forecast isn’t pulled out of thin air. It is grounded in significant investments, burgeoning start-ups, and an increasing number of patents filed in this domain.

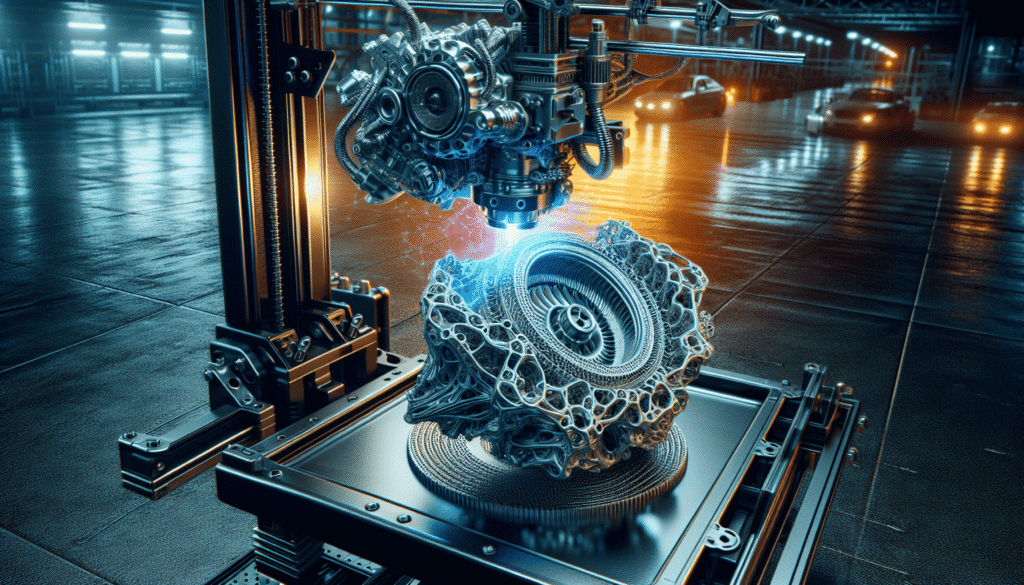

Trend 1: Mainstream Adoption Across Industries

In the coming years, many industries will adopt 3D printing—not just as a novelty but as a staple of their manufacturing processes. Automotive, aerospace, healthcare, and even fashion are already experimenting, and their trials are showing promising results.

Automotive Industry

Take the automotive world, for instance. Companies are increasingly using 3D printing to produce parts. Why? Reduced waste, increased customization, and shorter production cycles make it irresistible. Imagine walking into a dealership and having your car parts printed on demand—exciting, isn’t it?

Healthcare Innovations

In healthcare, 3D printing is poised to revolutionize prosthetics, dental implants, and even organ transplantation. The ability to create patient-specific models is crucial for complex surgeries and individual medical needs. By 2025, the very notion of ‘one-size-fits-all’ could be deemed antiquated.

Trend 2: Material Innovations Drive Growth

Innovation doesn’t stop with the machines; it’s in the very materials used. Initially confined to plastics and certain metals, 3D printers can now work with ceramics, composites, and bio-materials.

Beyond Plastics

The expansion into new materials is staggering. Companies are delving into biodegradable and recycled materials as sustainability becomes a driving force. This not only opens up new applications but also addresses the mounting concerns about plastic waste.

Bioprinting on the Rise

Let’s talk about bioprinting—a beacon of hope for creating tissues, organs, and even bones. By 2025, what seems like science fiction might just become science fact. The implications of this are profound, especially for those awaiting organ transplants or needing long-lasting implants.

Trend 3: Enhanced Speed and Precision

Speed and precision in 3D printing have seen remarkable improvements and are expected to advance even further by 2025. Where projects once took days, newer printers promise outcomes in mere hours without compromising quality.

The Role of AI and Machine Learning

Enter artificial intelligence and machine learning to crank things up a notch. These technologies offer predictive analytics and real-time problem-solving capabilities, enhancing the efficiency and accuracy of prints.

Precision Engineering

Everything from tiny circuit boards to life-sized sculptures will benefit. Imagine the implications for research and development where speed and precision are non-negotiables.

Trend 4: Customization Becomes King

Consumer demands are steering towards unique, customized products, and 3D printing is the monarch presiding over this new order. Personalization will no longer be a luxury but a consumer expectation.

Personalized Products

By 2025, expect to see everything from custom footwear to tailored furniture—each item geared precisely to the owner’s specifications. Customization is not just aesthetically appealing but can enhance product functionality.

Impact on Fashion and Design

In the realms of fashion and design, the blend of artistic creativity and technological capability could create masterpieces once deemed impossible. The result? A fashion industry that bends to personal taste, one layer at a time.

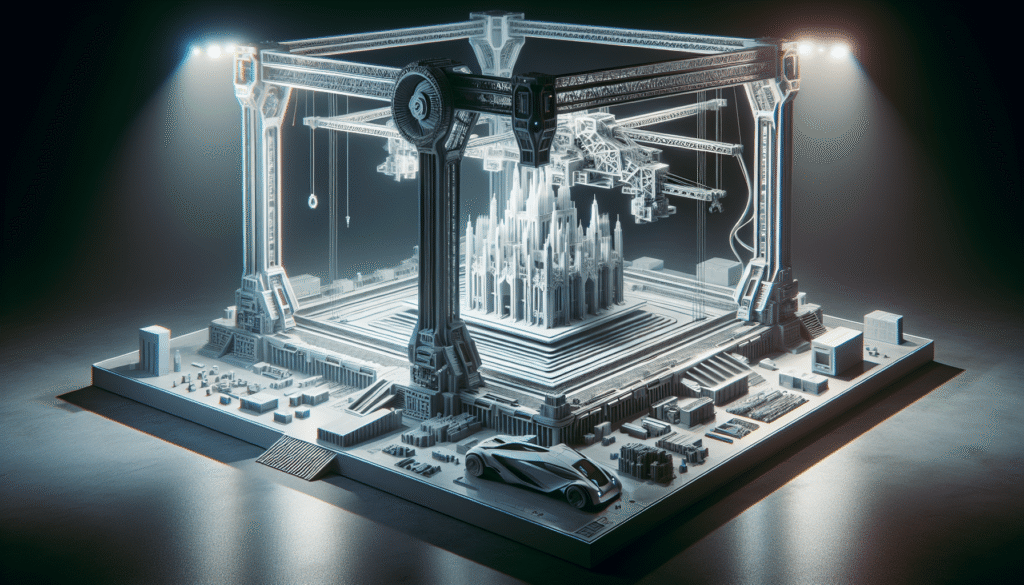

Trend 5: Distributed Manufacturing Models Take Hold

Remember—or perhaps imagine—a time when manufacturing was centralized in large factories in specific locations? Distributed manufacturing changes this narrative, positioning it closer to the consumer.

Local Production Benefits

Imagine localized 3D printing hubs minimizing the need for long-distance shipping, thus reducing carbon footprints and logistical expenditures. It heralds an age where production can meet demand with precision and veracity.

Small-Scale Empowerment

In every nook and corner of the world, small businesses and entrepreneurs could leverage distributed manufacturing to launch products without massive initial investments, opening doors for innovation and competition.

Trend 6: Regulations and Standards Evolve

As with any industry on the verge of transformation, the 3D printing universe is under the scrutiny of regulations and standards, especially as the technology extends its reach into critical sectors.

Safety and Compliance

Ensuring the safety and reliability of 3D printed items will be paramount. This involves everything from maintaining material integrity to ensuring the structural reliability of components destined for human use.

Intellectual Property Concerns

Navigating the intricate dances of copyrights and patents will prove essential. Licensing agreements might become the norm, governed by standards to protect intellectual property as well as consumer safety.

Trend 7: Sustainability as a Core Focus

In a world increasingly grappling with climate change, sustainability is far more than a buzzword. By 2025, 3D printing will dearly embrace it as a guiding principle.

Sustainable Practices

Recycling and using eco-friendly materials will become standards rather than exceptions. It will likely be a compelling competitive differentiator, attracting environmentally-conscious consumers and investors alike.

Energy Consumption

Techniques and machines that consume less energy are critical to the industry’s sustainable future. Energy-efficient machines could help balance out 3D printing’s carbon footprint, inching the industry closer to zero-waste manufacturing.

Trend 8: Increased Investment and M&A Activity

In the financial cosmos, 3D printing shines brightly. There is an influx of investment into companies both big and small, fostering a fertile ground for mergers and acquisitions.

Venture Capital and Start-ups

Small start-ups are receiving venture capital injections; their innovative approaches could disrupt established players. It’s like David facing several Goliaths, each armed with technology rather than a mere slingshot.

Corporate Moves

Established corporations are also making strategic acquisitions to strengthen their foothold in the market. By 2025, the industry could see enhanced collaboration between technology providers and end-user industries through these mergers.

Trend 9: Educational Initiatives and Skill Development

As with any industry undergoing rapid change, education and training rise to the fore, necessitating an evolution in curricula and skills.

Workforce Re-skilling

Manufacturing professionals may need to upskill or reskill to remain relevant. Educational programs could proliferate, centered on equipping individuals with the acumen to harness 3D printing technology effectively.

Academic and Industry Collaboration

Universities and industries are already collaborating to develop courses and training modules. By 2025, expect more integrated initiatives designed to produce professionals ready for a 3D future.

Trend 10: Global Market Expansion

The global market for 3D printing is set to expand, with growing interest in regions previously untapped by this technology.

Emerging Markets

Countries in Africa, South America, and parts of Asia show significant potential for market penetration. These regions could leapfrog into advanced manufacturing capabilities, bypassing traditional barriers.

Localization and Adaptation

Localization of technology will be crucial—machines and materials adapted to local needs and conditions. This adaptability could spur the rise of indigenous industries that were once beyond imagination.

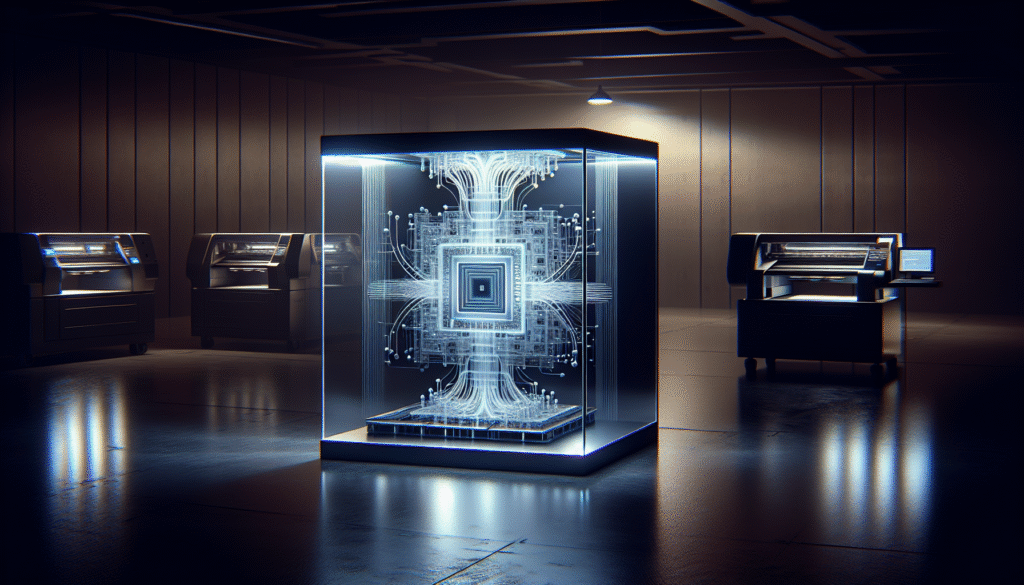

Trend 11: Convergence with IoT and Industry 4.0

3D printing is not evolving in isolation. It’s on a collision course with other advancements like the Internet of Things (IoT) and Industry 4.0, promoting synchronized, smart manufacturing.

Smart Manufacturing Synergy

By integrating 3D printing with IoT, manufacturers can implement real-time monitoring and predictive maintenance, minimizing downtime and enhancing efficiency across production lines.

Data-Driven Insights

The ability to harness data for iterative design improvements will align manufacturing with the stringent demands of modern-day production, maintaining quality and precision.

Trend 12: The Rise of Service-Based Models

Notably, many companies are transitioning to service-based models, offering 3D printing as a service rather than a product.

Subscription and Cloud Services

This transition will empower companies to capitalize on the benefits of 3D printing without the burden of capital investments in equipment. Like streaming services for entertainment, on-demand access to 3D printing facilities could transform manufacturing processes.

Impact on SMEs

Small and medium-sized enterprises could find themselves increasingly competitive, accessing state-of-the-art equipment and services without the need for significant physical infrastructure.

Conclusion: A New Era Beckons

The crystal ball for 3D printing in 2025 is not murky; it’s exciting and inviting. The trends suggest nothing less than a metamorphosis of the manufacturing landscape. Adopting these innovations signals a movement towards customization, sustainability, global inclusivity, and tighter integration with emergent technologies. As we march toward this transformative era, the only limit seems to be the boundaries of our own imaginations.