Have you ever wanted to print a helmet the size of a small pumpkin without splitting it into seventeen parts and pretending the seams are “battle damage”?

Why I Chose the Creality Ender 5 Max for My Workshop

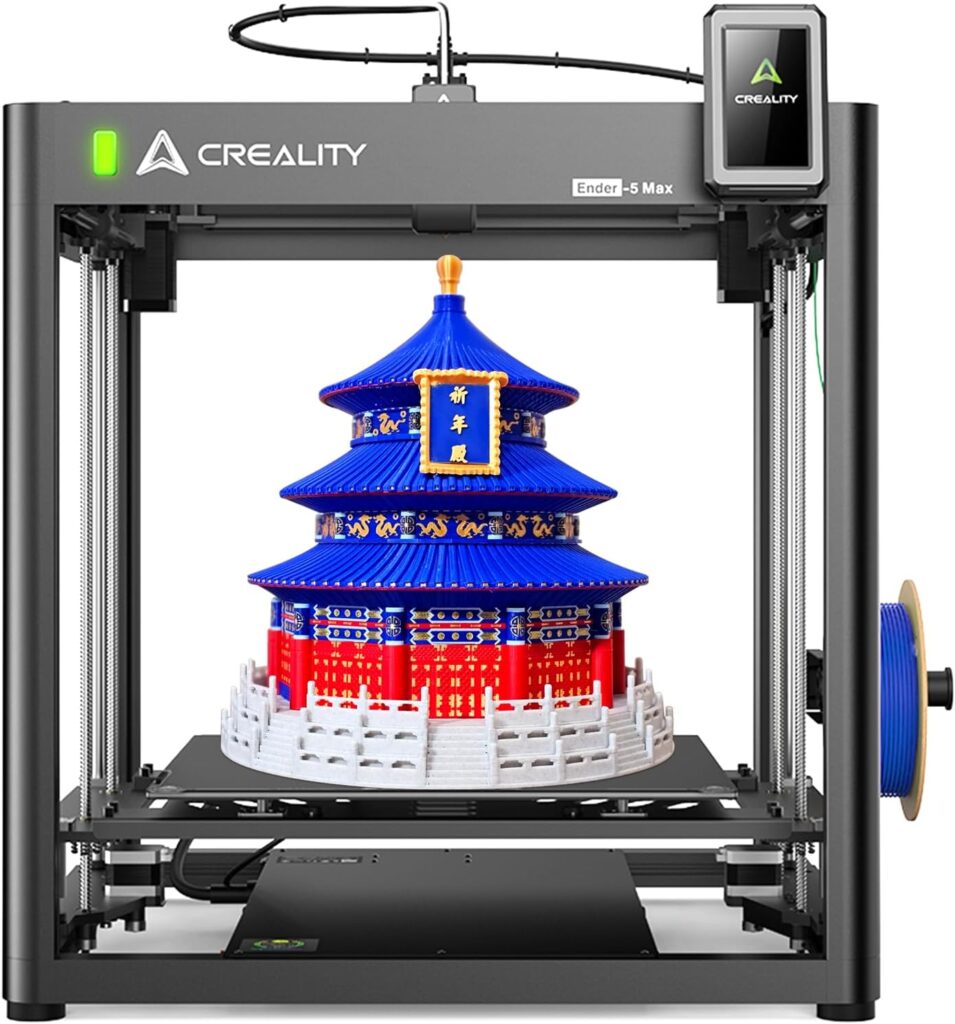

I wanted a machine that could keep up with my restless enthusiasm and occasionally questionable ideas. The Creality Ender 5 Max 3D Printer, 3D Printing Machine with 700mm/s High-Speed Printing, 400 * 400 * 400 Large Print Area, 64-Point Auto Leveling 300℃ High Temp Precise Linear Rail looked like a printer that was ready to say yes to too many things.

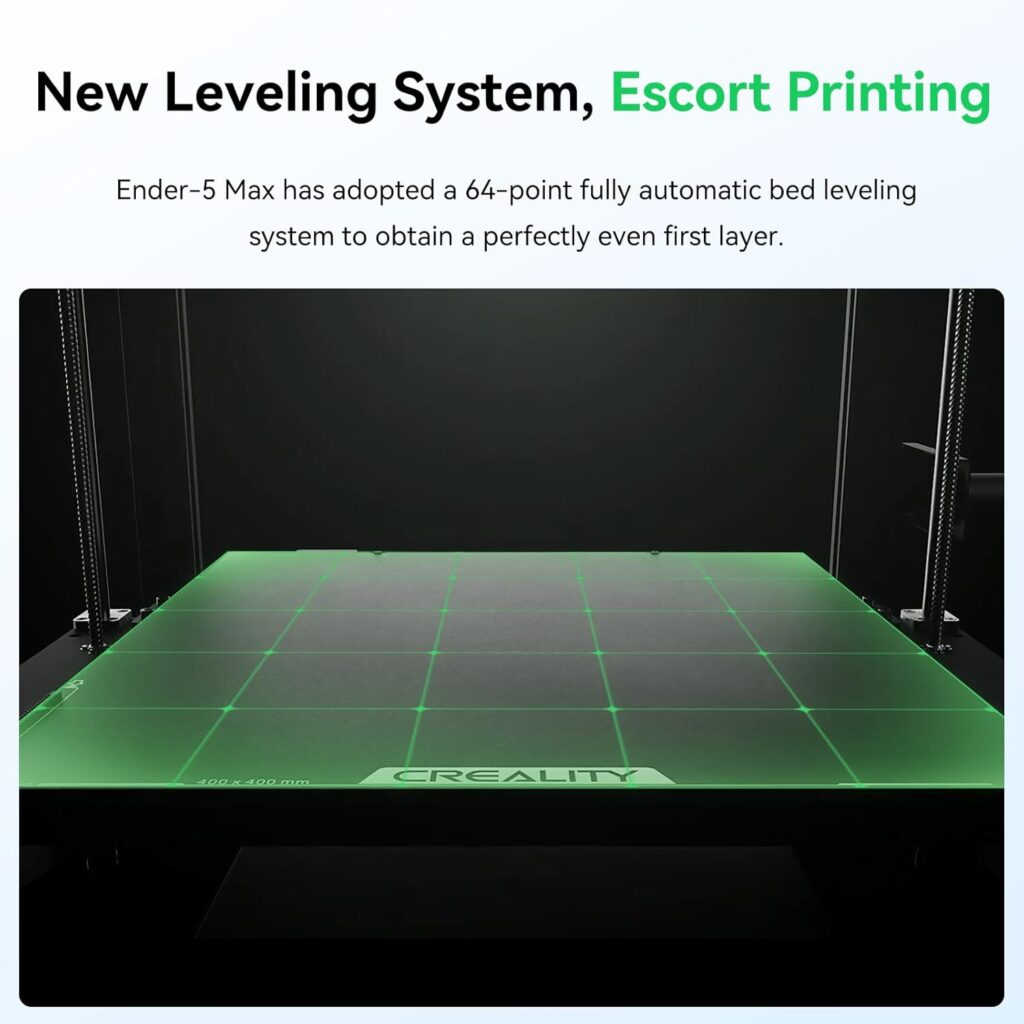

I wasn’t only tempted by the headline speed. The promise of a 64-point auto-leveling system, a 1000W heatbed that heats in minutes, a high-temperature hotend, and the kind of build volume that makes action figures tremble—those details made me feel like I’d found a printer designed for my particular brand of ambition.

Creality Ender 5 Max 3D Printer, 3D Printing Machine with 700mm/s High-Speed Printing, 400 * 400 * 400 Large Print Area, 64-Point Auto Leveling 300℃ High Temp Precise Linear Rail

$749.00 In Stock

Unboxing and First Impressions

I opened the box with the careful optimism of someone who’s built furniture from an unnamed flat-pack store. The packaging was tidy and confident, with the major components separated into foam compartments and the hardware bag organized well enough that I briefly suspected someone had cleaned it twice.

Right away, the frame felt solid. The Ender 5 layout—boxy, symmetrical, and deeply pragmatic—has a steady charm, and with the precise linear rail hardware fitted to keep the axes true, everything felt like it was built to move fast without shaking itself silly. I also noticed the heavy heatbed assembly and had a quiet word with my workbench about stamina and mutual support.

What Was in the Box

The bundle included the usual collection: the frame pieces, motion assemblies, hotend and carriage, the large aluminum alloy heatbed, the power and control components, and a small stash of tools and spare nozzles. There was a coil of filament for test prints, a scraper, and a few sample parts and documents to get me started.

I appreciated the clear labeling on most parts and the reasonably straightforward manual. I still had to pause once or twice to make sure I wasn’t assembling a rotating spice rack by accident, but the layout made sense once I attached the gantry and squared everything.

Assembly Experience

The build felt steady and methodical. I tightened bolts, squared the frame, routed cables, and had a few moments where I questioned whether my Allen keys were rebelling against me. But the components lined up without argument, and the linear rail runs felt smooth and deliberate.

With the power supply mounted and the motion system aligned, I checked belt tension and made sure the bed moved freely without sway. The only moment that made me pause was securing the bed with its 1000W heater—there’s something humbling about holding a component that will get hotter than my favorite pan.

The First Power-On and Firmware Check

I turned it on and watched the screen do its careful introduction. I checked the firmware version, looked for any prompts for calibration, and wandered into the menus to find the auto-leveling routine and motion controls. I’m not quite the sort of person who reads documentation like a bedtime story, but I do like to be sure I’m not about to launch a print into the stratosphere.

The menu was straightforward, and the machine’s first movements were smooth and confident. There was a light on the frame—a three-color status indicator—that felt unapologetically theatrical. It’s visible from across the room, even across the house, and I liked that it spoke in color instead of beeps.

The “Perfect First Layer” Promise and How It Played Out

A good first layer is like a good first paragraph. If it works, you can forgive a lot later. The Ender 5 Max’s 64-point fully automatic bed leveling promised exactly that: a strong start, no fiddling.

I ran the auto-leveling routine and listened to the bed quietly ping its way through dozens of coordinate points. The map it built was the printer’s way of confessing that my bed was slightly not-flat and that it had a plan to compensate. I still set my Z-offset manually—old habits are hard to quit—but seeing the mesh engaged gave me that rare feeling of calm usually reserved for people with tidy closets.

Dialing In Z-Offset Without Hand-Wringing

I used a sheet of paper for the Z-offset, because I’m a sentimental person and because it still works. The first test line went down with almost eerie consistency. When I stretched the print across the full 400 × 400 area, the layer thickness stayed uniform, and I found myself believing I could actually print a one-piece face shield or a big architectural model without the corners lifting like a bad mood.

Of course, I still had to make small adjustments for different materials—PETG likes to be a smidge higher, ABS appreciates a little warmth and space—but the baseline was solid. The leveling system took the drama out of the process, which left more room for the drama in the designs.

The High-Speed Printing Claim: 700 mm/s and My Reality

When I first read “700 mm/s,” I thought of it like a car speedometer. It’s nice to know it can go that fast, even if I plan to mostly commute to the grocery store. Speed in 3D printing is a mix of velocity, acceleration, mechanical precision, and how fussy your filament is on Tuesdays.

Powered by 42-76 stepper motors on the X and Y axes, the motion system felt muscular. It moved with confidence, and I didn’t hear the kind of rattling that tells you there’s a bolt somewhere practicing escape artistry. At aggressive speeds, the frame stayed composed, and the linear rails kept the head from wobbling as it did the fun kind of zigzag.

My Working Speeds and Settings

In practice, I found my happy place around 250–350 mm/s for detailed parts. On larger, less intricate pieces—helmets, props, chunky enclosures—I pushed to 400+ mm/s. Using high infill speeds while keeping outer walls more conservative was a good compromise for surface quality.

I could coax 500 mm/s on infill without things sounding like a set of castanets, and while 700 mm/s is achievable under the right conditions (especially for sparse infill and travel moves), I considered it more of a party trick than a daily target. Still, it’s satisfying to see a machine that doesn’t grimace when you ask for more.

The 1000W Heatbed: Fast Heat, Big Confidence

The heatbed heats fast. In about 200 seconds, it was already cruising toward 80°C, and my tea hadn’t even steeped with conviction yet. That quick ramp was a small joy because I spend too much of my life waiting for things to warm up.

The build plate offered consistent heat across its spacious aluminum surface, which was vital when printing big parts that love to stress-test the corners. Getting to 100°C for ABS and ASA took a bit longer, but it was still reliably quick. I kept an eye on power usage with a smart plug out of curiosity, and while the 1000W draw felt significant, the total time to temperature was short enough to keep energy use very reasonable.

Adhesion and Surfaces

I used a sheet on the bed for most prints, with a bit of glue stick for nylon and ABS when the weather turned uncooperative. PETG stuck like a loyal friend and sometimes needed a nudge to let go, so I tweaked bed temperature and Z-offset to help. With larger prints—think giant organizer boxes or the questionable decision to print a one-piece lamp—I appreciated that the heat distribution stayed even enough to prevent the corners from curling into modern art.

Build Volume: 400 × 400 × 400 mm of Possibility

I can be greedy about build volume. I liked batching small prints across the bed like I was running a tiny factory, but I also loved putting down one enormous piece and letting it run through the night like a very determined racetrack.

Printing big single parts comes with its own theater: filament changes, anxiety about power flickers, and the quiet ritual of measuring the printed object against the doorway it needs to pass through. But the Ender 5 Max treated big jobs with the steady attitude of a seasoned stagehand who’s heard it all before.

Practical Uses for the Space

I printed large cosplay armor in single sections, inset signage, oversized containers with functional threads, and architectural sections that made my desk look like a tiny city had flourished overnight. For small runs, I arranged at least six medium parts across the bed and let it go—yes, it’s a little unnerving leaving it unattended, but the status light’s visible signal made pass-by checks simple.

For ABS and ASA, I used a makeshift enclosure to keep drafts out. The open-frame design can handle a lot, but if you’re printing big ABS parts on a winter afternoon with a window cracked open for “fresh air,” you’ll want a tent, a box, or a curtain to keep the print conditions stable. In my case, a homemade enclosure from foam board and magnets did the trick.

Materials: From Everyday PLA to More Demanding Polymers

The 300℃ high-temperature capability meant I could stretch beyond basic materials. PLA printed like a dream, PETG was cooperative once I taught it boundaries, and ABS and ASA were absolutely viable as long as I respected their need for a warmer world.

PA (nylon) was an option I reserved for functional parts that needed toughness and flexibility. It liked higher temps, more patience, and hydration levels usually associated with a cactus. I dried the spool, used a slightly textured surface, and laughed at how it managed to warp a little even when I thought I had it cornered. Still, once I got it right, the parts were beautiful and durable.

Nozzle and Hotend Behavior

With a hotend capable of 300℃, I leaned into engineering-grade settings for the materials that demanded it. I didn’t assume any specialty nozzle material, so I treated abrasive filaments carefully and swapped nozzles for composites or glow-in-the-dark materials. The thermal stability felt steady, and I didn’t see temperature swings that caused layer lines to change personality mid-print.

Retraction and flow settings needed tweaks for speed. At high rates, I trimmed retraction lengths and relied on faster travel moves to prevent stringing. For PETG, a small fan adjustment saved surfaces from becoming too glossy and sticky.

Linear Rail Precision and Motion Confidence

Precise linear rails aren’t shy about their purpose: they keep the movements straight, true, and repeatable. I noticed cleaner corners than I expected at higher speeds, which meant the machine wasn’t fighting itself during sharp changes in direction.

That mechanical rigidity is what separates energetic printing from wild printing. Ghosting on surfaces stayed minimal when I kept accelerations sensible for the model geometry, and I didn’t have to chase loosened components every weekend like a hobbyist plumber. The rails did the serious work in the background so the visible results could be calm.

Stepper Motor Performance

The 42-76 stepper motors on X and Y felt like they were carved out of focused strength. They delivered motion without stutter, handled quick reversals with composure, and kept layers aligned even during long prints that required endurance. I liked that the motors didn’t run hotter than my comfort zone, and the overall motion system seemed engineered to encourage risk-taking—responsibly, as one should with spinning blades and unpronounceable polymers.

A Quick Look at the Specs Versus My Reality

Sometimes I like to set my hopes next to my actual outcomes and see if they’re compatible roommates. In this case, the advertised features mostly matched my day-to-day results, with the usual caveats that come with real-world printing.

| Feature | Manufacturer Claim | My Experience |

|---|---|---|

| Print Speed | Up to 700 mm/s | Excellent for fast infill and simple geometries; I usually run 250–400 mm/s for best quality. Peaks above 500 mm/s are feasible in certain situations. |

| Build Volume | 400 × 400 × 400 mm | As advertised and glorious. Batching and one-piece large models are practical. |

| Leveling | 64-point auto leveling | Consistent mesh compensation; first layers across the whole bed are reliably even after Z-offset tuning. |

| Heatbed | 1000W; 80℃ in ~200 seconds; max 100℃ | Heats quickly and evenly; big benefit for ABS/ASA and larger parts. Power draw is short and strong. |

| Hotend Temp | Up to 300℃ | Stable at high temps; supports PLA, PETG, ABS, ASA, and PA with proper settings. |

| Precision | Precise linear rail | Improved accuracy at speed; minimal ringing when accelerations are set thoughtfully. |

| Status Light | 3-color, visible up to 10 meters | Genuinely helpful for a quick glance update across the room. |

| Materials | PLA, PETG, PA, ABS, ASA | All workable. PETG and nylon need small adjustments; ABS/ASA prefer an enclosure. |

Print Quality: Walls, Details, and the Sort of Corners That Make You Proud

On default profiles, the Ender 5 Max produced clean walls that didn’t embarrass me under a desk lamp. Quality held up even when I printed more aggressively, as long as I kept outer walls slower and focused speed where surface finish didn’t matter.

Overhangs behaved with adequate cooling, bridges spanned respectably, and dimensional accuracy stayed dependable across the large area once I equalized temperatures. I measured parts that when scaled up can drift, but with proper tuning they came out within the tolerances I needed for functional assemblies.

What I Tweak for Best Results

I often adjusted jerk and acceleration to match the geometry. For parts with delicate lettering or small recesses, I favored slightly slower outer walls. For chunks of material, like brackets and cases, I let the machine flex its speed. Filament choice mattered too: crisper PLA grades delivered finer details at lower temperatures, while PETG rewarded me for turning down cooling and stepping up the bed temperature.

Noise, Vibration, and Nighttime Printing

The printer’s motion system felt composed, but it’s still a large machine moving at pace. At moderate speeds, noise was perfectly acceptable in a home workshop. At high speeds, there was the expected whoosh and a spirited chorus from the fans, but not the rattling drama I’ve heard from some large-format setups.

Vibration stayed under control. The heavy heatbed and steady frame helped absorb motion, and careful placement on a stable table made a difference. For overnight prints, I moved it a little farther from the bedroom and let the status light do its job as the most polite night light I’ve ever owned.

The Three-Color Status Light: Simple and Weirdly Reassuring

There’s something satisfying about getting the status of a machine without staring into its interface. The Ender 5 Max’s three-color light can be seen from up to 10 meters away, which in my house meant I could check on it from the kitchen without abandoning my toast.

Color-coded signals for ready, printing, and attention saved me from those half-sprints to the workshop when I wondered if a print had finished or if it had decided to reinvent itself as a modern sculpture. It sounds simple, and it is, but useful things often are.

Interface and Usability Notes

The interface itself is clear enough, and the menus are where I expected them to be. Manual controls for axes and temperatures behaved, and I could trigger auto-leveling and preheat routines with a few clicks. I didn’t get lost, which is all I ask from a device that already has my patience stored for troubleshooting other things.

Safety and Power: Respecting the Heat and the Watts

I treated the 1000W heatbed with the respect I usually reserve for powerful appliances and new acquaintances. The power draw during heat-up is strong, but short; I used a properly rated outlet and kept the power cable tidy and un-pinched.

I also gave the machine some breathing room for ventilation. The hotend and bed are basically a small furnace and its cheerful assistant, so airflow matters. For ABS and ASA, I used an enclosure to keep heat in and odors out, and I ventilated the space gently to avoid trapping fumes.

Maintenance: The Quiet Rituals That Keep Things Lovely

There are a few things I do regularly that keep the Ender 5 Max on my good side. I clean the bed after every few prints with isopropyl alcohol, especially after PETG. I check belt tension and give the rails a quick inspection, just in case some errant filament fuzz has decided to stage a sit-in.

I vacuum or brush out the hotend area so dust doesn’t gather and cause surprise insulation. I also look over the wiring and connectors once in a while to make sure nothing has worked loose. It’s the kind of maintenance that feels like TLC more than repair—small habits, big payoff.

Consumables and Spares

I keep spare nozzles ready, and I have a few bed surfaces I rotate depending on the filament. The occasional new Bowden tube or extruder gear cleaning doesn’t hurt. For the size of the machine, the upkeep feels routine and manageable, the way tidying a large desk takes more time but not more talent.

My Test Prints: What I Ran and What I Learned

I started with a first-layer calibration square, because I’m sentimental and I like clean corners. Then I printed the usual suspects: a calibration cube, a speed test, and a small functional bracket that I secretly rely on to judge a printer’s mood.

From there, I printed a large storage box with a threaded lid to test fit across the full bed. The threads aligned, the lid didn’t wobble, and I had the satisfying experience of screwing it on and off several times with the quiet triumph of someone who enjoys lids more than is conventional.

Big-Piece Challenges

A single-piece cosplay shin guard went on next, and it politely used most of the height and width. The first layer held beautifully after the 64-point auto leveling, and I didn’t see warping even at scale. For ABS, I switched to an enclosure, bumped the bed to near 100°C, and enjoyed the steady temperature profile that the 1000W heater made possible.

Tips That Saved Me Time and Sanity

- I store nylon and PETG in dry boxes and dry them before printing; it cuts down on stringing and makes layers crisper.

- I slow the first few layers slightly, not because the machine needs it, but because my nerves do. It improves adhesion and calms me.

- I keep outer walls slower for surface finish and treat infill like a sprint. The balance lets me have both speed and beauty.

- I adjust retraction length down a touch at high speeds, and I use higher travel speeds to prevent oozing.

- I double-check the bed mesh after moving the printer or changing anything major. It’s quick, and it prevents mysterious first-layer angst.

Troubleshooting: The Usual Suspects and Their Alibis

When I saw light ringing at corners on a fast print, I turned down acceleration and jerk slightly and watched the artifacts disappear like an apology. When I got PETG blobs at retractions, I shortened retraction and raised the nozzle temperature a hair.

Warping on big ABS parts surrendered after I sealed my enclosure better and raised the bed temp. For nylon, a textured surface and a brim gave the first layer a friend to hold onto. Every printer has a personality; this one’s personality is “Give me a minute to realign, and I’ll behave.”

Energy and Time: The Arithmetic of Printing Big and Fast

A big bed, a powerful heater, and fast movement are tools, and like all tools, they ask us to think a little. The Ender 5 Max heats quickly and prints fast, which means the power draw spikes early and then glides. I found the total energy use often lower than slower printers because it got to work and finished before I grew old.

I preheated as needed, avoided long idle times with the bed on, and consolidated prints into batches to make the most of the warm-up. The status light helped me time room visits better, too, which felt like a small mercy for my legs.

Who I Think This Printer Is For

I’d recommend the Ender 5 Max to ambitious hobbyists, prop makers, and small shop owners who want to produce large parts quickly and with confidence. It’s for the person who wants to print a helmet in one go, batch a dozen functional pieces overnight, or produce an architectural model that commands the mantle.

Educators and makerspaces with proper supervision would appreciate the fast heat, the big bed, and the reliability of a machine that doesn’t need constant babying. It’s powerful enough to feel exciting and consistent enough to feel trustworthy.

Pros and Cons After Weeks of Printing

Here’s my emotional summary sheet, written after both triumphs and the occasional filament tantrum.

-

Pros:

- Large 400 × 400 × 400 mm build volume opens the door to ambitious projects and efficient batching.

- 64-point auto leveling creates a reliable first layer across the entire bed and saves time every session.

- High-speed motion system with robust 42-76 stepper motors feels strong and stable.

- 1000W heatbed heats fast and evenly, supporting materials like ABS, ASA, PETG, and PA with confidence.

- 300℃ hotend capability extends material options and future-proofs projects.

- Precise linear rail motion reduces play and keeps prints clean, even at brisk speeds.

- Three-color status light is genuinely useful for quick status checks from across the room.

-

Cons:

- The physical size and power draw require a proper workspace and a good outlet.

- Peak speeds require thoughtful tuning to avoid surface artifacts; the “up to 700 mm/s” headline needs practical expectations.

- For ABS/ASA, an enclosure is advisable, which adds space and setup complexity.

- PETG adhesion can be a bit clingy on certain surfaces; plan for surface care and release strategies.

- Noise at top speeds is noticeable; I kept it in a separate room for overnight runs.

Comparisons in My Head Without Naming Names

I’ve used smaller printers that produced exquisite detail but couldn’t fit a decent-sized prop without slicing it into emotional pieces. I’ve tried budget machines that claimed speed but shook themselves silly after an hour at pace. The Ender 5 Max sits in a productive sweet spot for me—big, fast, and composed—without tipping into the fragile or the fussy.

I didn’t feel like I had to coddle it, and I didn’t have to sacrifice quality to use its speed. The auto leveling and the linear rails make it feel more grown-up than the average hobby printer, while still inviting me to try silly projects and get serious results.

The Learning Curve and the Plateau

My first week was filled with calibrations, fast prints that were a touch too optimistic, and a lot of small tweaks that made me feel like I speak filament as a second language. After that, the curve flattened into something comfortable. I had profiles I trusted, materials I knew well, and results that no longer felt like a surprise each time.

That’s one of the hidden joys of a good printer: it lets you stop thinking about the printer and start thinking about the thing you’re making. The Ender 5 Max crossed that line sooner than I expected, especially for a machine with this much volume and speed.

A Few Print Ideas That Made Me Smile

- One-piece cosplay helmets and armor sections that felt like props, not patchwork.

- Large containers with threaded lids that actually fit, with satisfying tolerances.

- Architectural wall sections with integrated channels that printed beautifully.

- A monolithic planter that refused to be anything but dramatic.

- Tool holders that turned into a small ecosystem along the workbench.

Safety Habits I Adopted Without Complaint

I used a smoke detector nearby because it takes no effort and gives me peace of mind. I kept filament spools tidy and off the floor because I like my ankles and my cat likes causing chaos. I used ventilation for ABS/ASA and occasionally for nylon because I enjoy breathing without commentary.

I also used power strips and outlets rated for the load, and I gave the machine a dedicated spot where cables weren’t being tortured. It felt like the sort of adult behavior that would make my parents proud.

What Surprised Me Most

The speed was real in spirit, if not always at the full advertised number. With sensible tuning, parts came off the bed much faster than I was used to, and the quality remained steady. The auto leveling worked like a quiet assistant who understands my desire for the first layer to behave without drama.

And the bed—oh, the bed. Heating to 80°C in just a few minutes never got old, especially when I remembered the winters I spent waiting for lesser beds to gather courage.

Long Prints and Trust

I ran a 20-hour print because I was feeling fearless and I wanted to know if I could trust this machine like a friend with a spare key. It hummed along through the night, probably judging my taste in audiobooks, and produced a part that looked like it had been made by someone more methodical than I am.

With long prints, filament care mattered, and I used a spool holder that moved smoothly and a filament guide to keep the path clean. I checked the status light occasionally, took photos like a proud parent, and fell asleep knowing the machine wasn’t plotting anything mischievous.

The Intangible Factor: Joy

There are printers that feel like chores. This one felt like a capable partner with a generous streak. The combination of speed, space, and stability meant I said yes to projects I might have hesitated to try before. When a printer nudges me into being more creative, I take note.

I also liked how it looked in the room. The squared frame and confident stance told visitors that I’m serious about plastic, which is a sentence that makes sense if you’re reading this and probably makes no sense to anyone else.

My Recommended Settings Starting Point

- PLA: 210–220℃ nozzle, 60℃ bed, 0.2 mm layer height, 150–250 mm/s walls, 300–400 mm/s infill, moderate cooling.

- PETG: 240–250℃ nozzle, 75–85℃ bed, 0.2–0.28 mm layers, slower first layer, reduced cooling, shorter retractions.

- ABS/ASA: 245–255℃ nozzle, 95–100℃ bed, enclosure, limited cooling, brim for larger parts.

- PA (nylon): 255–275℃ nozzle, 70–90℃ bed, dry filament, textured or adhesive surface, minimal cooling, enclosure if possible.

These are not absolute truths, just what worked for me. The machine is adaptable, and a small change in temperature or speed can turn a good print into a great one.

Accessories I Actually Used

I used a simple filament dryer for hygroscopic spools, a textured PEI bed for nylon and ABS, and a smooth sheet for PLA that made the bottom layers look polished. I kept a set of nozzles on hand and a thin spatula for careful part removal.

A smart plug helped me track power and occasionally shut down heat after a long session. None of it felt extravagant. It felt like giving a good printer the environment it deserves.

My Favorite Feature I Didn’t Expect to Love

It’s the status light. I know that sounds like the sort of thing you’d shrug at, but it changed the way I monitored prints. Instead of walking over to check a screen, I’d glance up, read the color, and return to pretending I wasn’t eating a snack at my desk.

It’s a small kindness, the sort that makes a machine feel like it understands I have other things to do than hover. And that, in a world built on waiting for layers to stack, feels generous.

Final Verdict: Why I’m Keeping It Front and Center

I’m keeping the Creality Ender 5 Max 3D Printer, 3D Printing Machine with 700mm/s High-Speed Printing, 400 * 400 * 400 Large Print Area, 64-Point Auto Leveling 300℃ High Temp Precise Linear Rail front and center because it fits how I like to work. It’s fast enough to matter, large enough to be fun, and stable enough to save me from the kinds of surprises that have me questioning my hobbies.

It handles PLA with grace, PETG with firm boundaries, ABS and ASA with a little environmental encouragement, and nylon with focused preparation. The 64-point leveling system gives me the kind of first layers that start a print with confidence, and the 1000W bed keeps the process moving at a modern pace. The linear rails and 42-76 stepper motors anchor the machine’s speed with precision, and the results look like the product of a team rather than a lone gambler.

If you’re the sort of person who dreams up impractically large projects and then makes them anyway, or if you just like the idea of a big, capable machine that doesn’t require a week of rituals to use, I think you’ll be as pleased as I am. It’s a printer that shows up prepared, stays steady, and—most importantly—turns your ambitions into objects you can hold without apologizing for the seams.

I’ve spent enough time with it to trust it, and enough time away from it to miss it. For a tool that heats plastic for a living, that feels pretty human.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.