Have you ever watched a machine move so quickly you instinctively pull your coffee back, as if a gust of wind might carry it away?

Why I Wanted a 1200mm/s CoreXY in My Life

I wanted to know if speed could coexist with sanity. The Sovol Zero promises 1200mm/s and packages it in a CoreXY frame with full linear rails, eddy current scanning, pressure sensing, a 350°C nozzle, a 120°C AC heated bed, air filtration, a built-in camera (compatible with Obico), and open-source flexibility. That’s the kind of resume that makes me suspicious and a little giddy.

I’ve owned printers that auditioned as space heaters and others that thought “auto-leveling” was more of a personal journey. This one looked like someone finally gave a to-do list to an engineer who’d been told “no” too many times. I brought it into my workspace with equal parts curiosity and protective optimism.

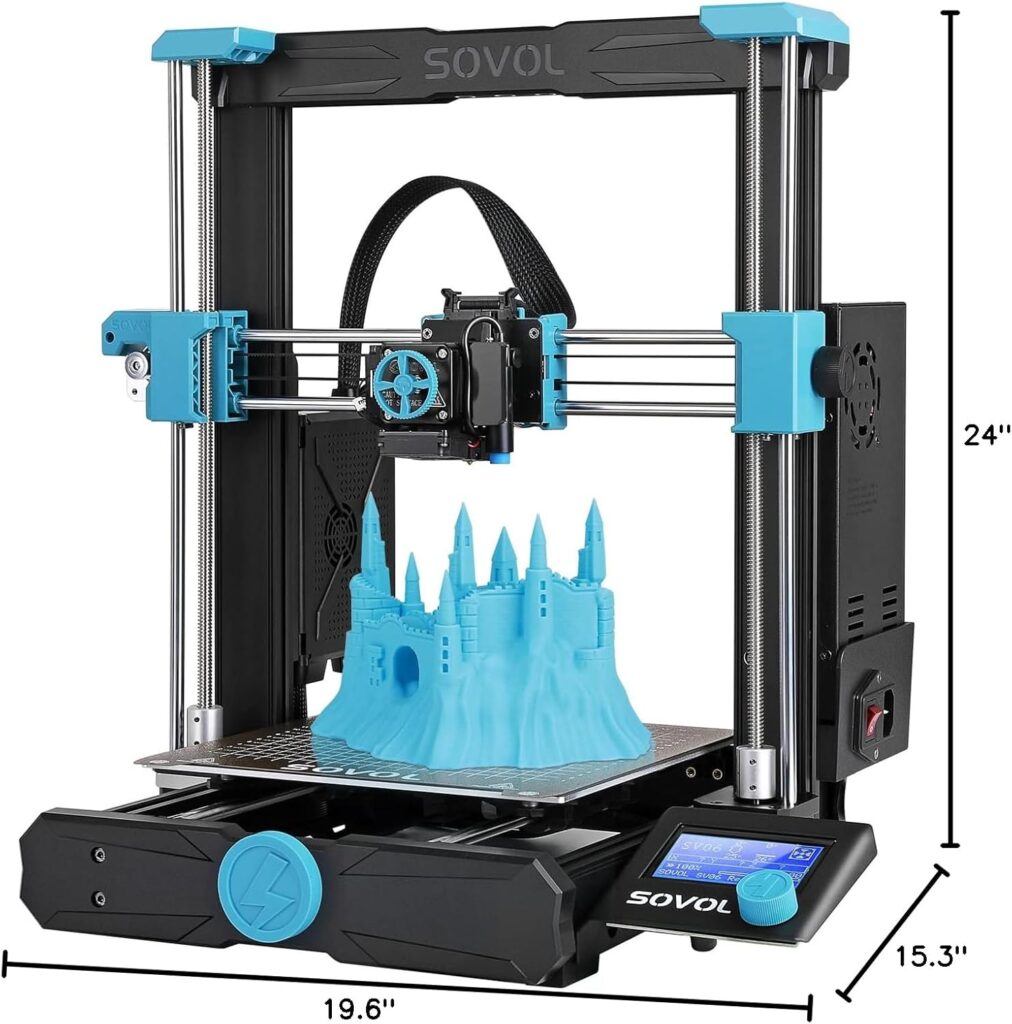

Sovol Zero 3D Printer, 1200mm/s High Speed CoreXY 3D Printers with Eddy Scanning & Pressure Sensing, 350℃ Nozzle & 120℃ Heated Bed Heating, XYZ Full Linear Rails Open Source Build Volume 6X6X6in

The Look and Feel: Compact Speed Machine with Intent

I judge machines the way I judge suitcases: What can it carry, how much rattling will it do, and will it embarrass me in public? With a 6x6x6-inch build volume, the Sovol Zero lives in that sweet spot between “big enough to be useful” and “small enough not to take over the room.” CoreXY means the print head darts around like a caffeinated librarian while the bed mindfully moves one axis.

The entire XYZ motion system rides on linear rails—actual metal rails, not v-wheels—and it shows. The motion is smooth, confident, and much less theatrical about it. The silicone damping pads quietly get rid of the jitters, like those anti-anxiety weighted blankets, but for a robot.

Setup and First Print: The Part Where I Try Not to Panic

Assembly was simple, which is saying something coming from someone who has accidentally worn filament desiccant as a scarf. The frame arrived square, the components were labeled, and the cables behaved. I powered it on, and the auto-leveling routine introduced itself like a competent barista: a quick, practiced dance of “I’ve got this.”

I didn’t shim, I didn’t chant, I didn’t manually twist any knobs while whispering affirmations to the bed. I used the included profile, loaded PLA, and printed a calibration cube without feeling like I was gambling my evening. When a printer works on the first try, I immediately get suspicious. But the cube was square, the first layer clean, and the layers stacked like tidy pancakes. Suspicion gradually surrendered to relief.

Auto-Leveling V3.0: Eddy Current Scanning Meets Pressure Sensing

I want to marry this system and invite it to every holiday. The Sovol Zero maps the bed using eddy current scanning—no physical poking—followed by pressure-sensing touchpoints to nail the precise Z offset. I’ve tried contact-only probes, and they’re like getting medical advice from a raccoon. The eddy method is faster, quieter, and less wear-prone, while the pressure step is the final whisper of precision.

The result is a bed mesh that just works, even as the plate expands or contracts during long prints. I never thought I’d prefer electromagnetics to manual feeler gauges, but my knuckles are grateful.

The Motion System: CoreXY Kinematics on Full Linear Rails

Here’s where the speed comes from. CoreXY reduces moving mass by keeping the bed motion minimal and letting belts handle the acrobatics. Add full linear rails on X, Y, and Z, and you get repeatable precision with less wobble and fewer artifacts. The silicone damping pad soaks up the vibes like a therapist who charges by the microstep.

I watched the gantry sprint at high travel speeds and felt that feeling you get when a car merges onto the highway and you realize the brakes are also excellent. The system feels balanced, not reckless.

The Speed Question: 1200mm/s and Real-World Results

Let me say the quiet part out loud: 1200mm/s is a thrilling number, and also a specialist scenario. Yes, it can do it; you see that capacity in travel moves, in very lightweight geometries, and in specific test prints. In daily life, I found my sweet spot for quality and reliability around 250–450mm/s for PLA and PETG, with aggressive acceleration on small features and faster infill.

The magic is not just the top speed; it’s how long the printer can maintain a high average speed with clean corners and consistent extrusion. That’s the difference between “fast for ten seconds” and “fast all night.” The Sovol Zero leans toward the latter. Prints that used to steal a weekend now happen between lunch and dinner. And when I pushed the settings, the frame didn’t shake like a washing machine trying to escape.

The Hot End: 350°C Nozzle and Willpower to Match

A nozzle rated to 350°C feels like a passport stamp to the grown-up filament world. PLA? Of course. PETG? Like butter, if butter had adhesion. TPU, ABS, ASA, Nylon blends, PC, CF-laden options—it’s ready if you are. I stuck to hardened or abrasive-resistant nozzles for carbon-fiber blends because I’ve watched brass nozzles erode like beach sand in a hurricane.

High temperature means the extrusion stays stable on longer moves, and the layers fuse confidently. I also love that it doesn’t panic during retractions or longer bridges, especially with filaments that usually behave like wet linguine.

The Heated Bed: AC Power, 120°C, and Fewer Coffee Breaks

I didn’t have time to wander around waiting for this bed to heat. The AC-powered plate reaches temperature quickly and holds it, which matters when you’re printing ABS or ASA and every minute counts. I attributed fewer early-layer failures to this stability—and to the bed mesh. The fact that there’s overheating protection made me breathe easier; I don’t want my workspace doubling as a sauna.

The bed handled everything I threw at it, including those edgy first layers where a part tries to curl away like a kid at bedtime. For high-temp filaments, a hot bed isn’t optional; it’s the difference between success and a six-hour lesson in humility.

Chamber Temperature Monitoring: The Quiet Helper

There’s a chamber temperature sensor watching the internal environment, and that matters more than people think. Warping loves inconsistency. A known and steady chamber temperature reduces bad behavior on ABS, ASA, and some nylons. Sovol notes an upcoming chamber heater component, which I would welcome. For now, the monitoring helps me choose speeds and ventilation with more confidence.

I’ve learned that controlling the climate inside the printer is like setting the mood for a date: too cold and things stiffen, too hot and you start sweating. This sensor helps keep the vibe right.

Air Filtration: Because I Like My Lungs

Printing high-temp filaments can smell like burnt science. The Sovol Zero includes an air filtration system designed to reduce VOCs and particles, and it makes a difference in day-to-day work. I still ventilate, because filters are not magic, and I prefer caution over headaches. But having filtration always on feels responsible, like flossing or wearing sunscreen even on cloudy days.

I appreciate that this works in tandem with the enclosed design and chamber monitoring. It makes the whole process feel more civilized.

Built-In Camera with Obico: Distant Supervision for the Anxious

The camera lets me keep an eye on prints without hovering. It does real-time viewing and time-lapse, which scratches the itch to watch perfection in motion. With Obico, I can check progress from anywhere—amazing for those moments when I remember a print is running while standing in the produce aisle.

Time-lapse video turned my calibration prints into oddly hypnotic entertainment. It also saved a few prints by showing me a layer adhesion issue early enough to stop, adjust, and restart before wasting material.

Open Source: The Door That Stays Open

Being open source means I can modify, tune, and tinker to my heart’s content. If I want to change a component or experiment with community mods, I’m not sneaking around. It’s empowering without being obligatory—perfect for the part of me that loves to swear at firmware on a Saturday and the part of me that wants to just hit “print” on a Tuesday.

Open platforms age more gracefully, thanks to an army of hobbyists who refuse to let good hardware go stale. It’s the kind of gift that keeps on tinkering.

Build Volume: 6x6x6 Inches of Real-World Utility

It’s easy to obsess over larger build volumes, but I’ve learned that most of my prints fit within this cube. When I want to make bigger things, I print in sections and bond them, which is oddly satisfying and far more stable long-term. The compact footprint means the machine doesn’t commandeer my space or turn the room into a heat bath.

If you routinely print helmets or furniture parts, you’ll need a larger bed. For most practical pieces, functional prototypes, and small batches, this size is nimble and efficient.

Print Quality: The Part That Makes Me Smug

I judged by calibration cubes, Benchys, structural brackets, and the occasional whimsical animal that serves no purpose but joy. Layer consistency was excellent, corners were disciplined, and bridging behaved. At reasonable speeds, I’d put the quality up against much slower machines and laugh when the Zero finished hours earlier.

With CF filaments, I got crisp features and less stringing than I expected. With TPU, I slowed things down and was rewarded with flexible prints that didn’t look like they’d been handcrafted by a nervous squirrel.

Noise and Vibration: Surprisingly Courteous

I expected the Sovol Zero to sound like a commuter train. It didn’t. High-speed travel is airy-whisper fast, and while you hear the motors and airflow, it never felt intrusive. The damping pads do their job, and the frame doesn’t telegraph every move to the desk. On long prints, the consistent hum becomes a kind of productivity soundtrack.

It’s not silent, but it’s civilized. I kept it in the office and still took calls without feeling like I needed to mute the machine or myself.

Reliability and Maintenance: Adulting, But With Grease

Linear rails need periodic lubrication, and the belts appreciate a tension check now and then. Keep the nozzle clean, swap the filter as needed, and don’t ignore the little hairs of filament that hide in the corners like dust bunnies with ambition. Treat it well, and it treats you better.

I ran long prints and batches, and the machine behaved. I didn’t see layer shifts or temperature tantrums. The bed adhesion stayed consistent, especially with the mesh and stable heat.

Software and Workflow: Smooth Enough to Stop Swearing

The included profiles got me in the ballpark fast. I adjusted for material specifics—retraction length, temperature, and fan curves—and saved a few stable favorites. I’m picky about slicers but not religious; the Sovol Zero didn’t force me into anything awkward. Open source meant I had options, and that lowered my blood pressure.

The camera and remote viewing completed the loop. I didn’t hover like an anxious parent. I hovered like an anxious parent holding a phone, which is progress.

Materials I Tried and Loved

I ran PLA for speed and sanity, PETG for practical parts, TPU when I needed bounce, and ASA for outdoor pieces. Carbon-fiber blends became my secret weapon for stiff, elegant parts that make people think I’m more competent than I am. With the 350°C nozzle and 120°C bed, the printer never felt out of its depth.

When I went with high-temp filaments, I slowed the exterior walls and made sure the chamber stayed warm and consistent. That’s when the sensor earned its keep.

Where It Shines—and Where It Doesn’t

This printer is designed to be a performance machine with precision. It rewards smart settings and decent filament. If you expect newtonian miracles at 1200mm/s with the cheapest spool you found at 3 a.m., you’ll be disappointed and possibly sticky. But if you run ambitious speeds with sane acceleration and cooling, it’s astonishingly productive.

The smaller volume will be a deal breaker for oversized ambitions. And while filtration helps, you still need ventilation with ABS or ASA. That’s not a flaw; that’s physics and chemistry.

Feature Summary and Real-World Takeaways

I like seeing features next to the actual way I use them. This is how it shakes out for me after living with the machine.

| Feature | What It Is | Why It Matters | My Take |

|---|---|---|---|

| CoreXY kinematics | Lightweight motion with belts | Faster, more precise X/Y moves | Speed without chaos; corners stay clean |

| 1200mm/s capability | Very high top speed | Shortens print time dramatically | Practically fantastic at 250–450mm/s for quality |

| Full linear rails (XYZ) | Metal rail guides | Smooth motion, longevity | Better than v-wheels; less maintenance drift |

| Auto-leveling V3.0 | Eddy current scanning + pressure sensing | Accurate, fast bed mesh | The first layer I dreamed of in therapy |

| 350°C nozzle | High-temp hot end | Handles advanced materials | Opens doors to CF, PC, and nylons |

| 120°C AC heated bed | Quick, stable heating with protection | Essential for high-temp filaments | Heats fast, holds temperature like a champ |

| Chamber temp monitoring | Sensor in the print chamber | Reduces warping | Great with ABS/ASA; I want the heater add-on next |

| Built-in camera (Obico) | Real-time monitoring and time-lapse | Saves time, catches failures | Remote peace-of-mind for anxious printers |

| Air filtration | Filters VOCs/particles | Cleaner indoor air | Helpful, but I still ventilate |

| Open source | Mod-friendly design | Community-driven improvements | Freedom to tweak, no locked doors |

| Build volume 6x6x6 in | Compact capacity | Fits most everyday parts | Efficient footprint, but not for helmets |

Practical Starting Settings That Worked for Me

Tuning is a lifelong journey where you get better and your standards rise. These baselines got me prints I was proud of without sacrificing my weekend.

| Material | Nozzle Temp | Bed Temp | Speed (Walls) | Speed (Infill) | Fan | Notes |

|---|---|---|---|---|---|---|

| PLA | 210–230°C | 55–65°C | 200–300mm/s | 250–400mm/s | 60–100% | Great for showing off speed without drama |

| PETG | 235–255°C | 70–85°C | 150–220mm/s | 200–300mm/s | 30–60% | Slow down on overhangs to avoid stringing |

| TPU (95A) | 220–235°C | 40–55°C | 40–80mm/s | 60–120mm/s | 20–40% | Direct path extrusion helps; minimal retraction |

| ABS/ASA | 240–260°C | 100–110°C | 160–220mm/s | 200–300mm/s | 0–20% | Keep chamber warm; use filtration and ventilation |

| Nylon (PA) | 255–275°C | 90–110°C | 150–200mm/s | 200–280mm/s | 0–20% | Dry filament religiously; prioritize adhesion |

| PC | 260–300°C | 100–120°C | 120–180mm/s | 200–260mm/s | 0–20% | Slow outer walls; stable chamber temps |

| CF blends | +5–15°C over base resin | 80–110°C | 120–200mm/s | 180–260mm/s | 0–30% | Use hardened nozzle; reduce retraction wear |

These are starting points, not commandments. I nudge acceleration, pressure-related settings, and cooling to suit geometry. Small parts get lower acceleration and more modest cooling; big parts get the opposite.

Real-World Print Stories: The Good, the Bad, and the Pretty

I printed a set of drawer organizers in PLA at 300mm/s walls and 400mm/s infill. They finished faster than it took me to decide what to put in them. The edges were sharp, and the infill pattern looked like it had been ironed by someone who cared.

I tried a structural bracket in PETG-CF and got a part that felt carved instead of extruded. Minimal stringing, and layers that bonded with conviction. For TPU, I slowed down, and the result was a flexible phone stand that bounced like a toddler and still refused to collapse.

ABS window clips turned out clean with no warping, thanks to the warm chamber and consistent bed temperature. I watched the time-lapse later and felt strangely proud, like I’d taught a squirrel to do calculus.

Everyday Usability: Hands-On Comforts

I love that I can start a print, check it from the living room, and not walk back in to find spaghetti. The auto-leveling means I spend less time with paper shims and more time doing literally anything else. The bed’s quick heat-up slashes the dead time between idea and plastic.

I didn’t worry about the belts stretching or the rails wearing prematurely. Everything felt like it was designed for the long game, not just the spec sheet.

Safety: The Serious Part I Actually Read

A 350°C nozzle and a 120°C bed are not trivial. The overheating protection on the AC bed is non-negotiable, and I’m glad it’s there. I keep the area clear, don’t leave flammable bits nearby, and use proper ventilation, especially with ABS/ASA and PC. The filtration helps with emissions, but it doesn’t replace fresh air and common sense.

This is not a toy. It’s a very polite power tool.

Who It’s For

I’d recommend the Sovol Zero if:

- You value high throughput and still want tidy, professional prints.

- You need to work with advanced filaments and want the thermal headroom to do it right.

- You’re happy with a compact build volume and care about enclosure behavior, filtration, and monitoring.

- You like open-source ecosystems and the satisfaction that comes with a mod-friendly machine.

I’d steer you elsewhere if:

- You primarily print oversized parts and can’t be bothered to segment models.

- You never intend to print materials beyond PLA and don’t value speed.

- You want something you’ll never tune or adjust. This one rewards curiosity and care.

Tips That Made a Big Difference for Me

A few habits paid off so consistently that I now evangelize them to anyone within earshot.

- Dry your filament, especially nylons and PC. If it sounds like frying bacon, it’s not dry.

- Use a hardened nozzle for carbon fiber and glass fiber. Brass will wear faster than your patience.

- Let the bed and chamber stabilize before starting high-temp prints. Five extra minutes can save five hours.

- Don’t chase the highest speed every time. Print fast where it counts and slow where it shows.

- Keep rails lubricated lightly and periodically. It’s the difference between “smooth” and “why is it squeaking like that.”

- Use the camera to catch the first layers. If the first layer looks great, the rest is mostly logistics.

- Save profiles for each material. “Pretty good and repeatable” beats “perfect and mysterious.”

Cost, Value, and the Time You Get Back

I try to think in hours saved rather than dollars spent. With the Sovol Zero running at sane but ambitious speeds, I finish more prints in a week than I used to manage in two. The camera keeps me honest; the filtration keeps me comfortable; the rails and kinematics keep the quality consistent. The open-source nature means I’m less likely to be stranded when I want to try something new.

It’s not just the speed—it’s the fact that speed doesn’t bulldoze quality. This is productivity you can live with.

Comparing to My Other Printers: The Reality Check

My older Cartesian workhorse still has a place. It’s predictable, slow, and endearing, like a dog that refuses to learn new tricks but will sit perfectly still forever. The Sovol Zero, on the other hand, is the friend you call when you need to move a couch up three flights in half the time and without dings.

On complex parts, the Zero cut runtimes dramatically without turning the part into modern art. On multi-part projects, the throughput changed my schedule. I started delivering things sooner, which made me look capable and oddly well rested.

Small Build Volume, Big Project Strategy

When I needed bigger prints, I designed interlocking joints and printed in sections. It’s easier to get perfect layers on smaller components, and assembling them gave stronger, more manageable pieces. A 6-inch cube might sound limiting until you realize most household and workshop items live happily inside it.

I used the leftover time to do small runs—things I used to postpone because of schedule creep. The Zero didn’t just make single parts faster; it made my whole workflow more nimble.

A Closer Look at First-Layer Consistency

The first layer has always been my ritual. Watching the Zero’s nozzle lay down that initial pass, I felt the calm that comes from knowing the bed mesh was accurate to a degree that human hands rarely achieve. The pressure sensing made the Z offset uniform across the plate, even after long prints.

Once I trusted that, I stopped babysitting. It felt like handing over the car keys to someone who actually drives the speed limit.

Filtration and Indoor Air: What I Noticed Day to Day

With filtration running, the usual tangy bite from ABS reduced to something I could tolerate while still choosing to ventilate. There’s a quiet assurance in knowing the machine is addressing the hazards instead of pretending they’re imaginary. I’m still not printing PC in a closet, but I’m also not holding my breath every time.

It’s rare to see this set of features assembled thoughtfully in one compact machine. It made the whole process feel higher-end without requiring me to wear gloves and a lab coat.

Troubleshooting Moments and How I Solved Them

Not everything was perfect—but the fixes were straightforward.

- A touch of ghosting at ultra-high acceleration on tall prints: I lowered acceleration for outer walls and kept infill fast. The result was crisp exteriors without throwing away the time savings.

- PETG stringing on intricate parts: I reduced nozzle temp by 5–10°C, increased travel speed, and lightened retraction. Strings packed their bags.

- Slight first-layer squish after a long print session: I reran the auto-level routine. The pressure sensing recalibrated the Z and the problem vanished.

These weren’t identity crises; they were personality quirks.

The Confidence Factor: Why I Keep Choosing It for “Important” Jobs

When I’m testing a fit, speed wins. When I’m producing a finished part that someone else will judge, quality wins. The Sovol Zero does both without throwing a tantrum. I’ve come to trust it when a part needs to look good and fit right, and I don’t have an evening to spare.

Reliability is its own kind of speed. I spent less time reprinting failures and more time pretending I had planned the schedule this way all along.

Key Specs and How They Translate to Real Life

Specs are promises; behavior is proof. Here’s how the machine’s headline features translated for me in use.

- 1200mm/s top speed: It can sprint, and those sprints shorten travel and simple infill times noticeably.

- CoreXY: Reduced mass means quick, clean direction changes and disciplined corners.

- Full linear rails: Less play and more precision, even on long prints.

- Auto-leveling V3.0: The best “set it and forget it” bed experience I’ve had.

- 350°C nozzle: Real high-temp compatibility, not marketing fluff.

- 120°C AC bed: Rapid heat-up and consistent adhesion—especially for ABS/ASA.

- Chamber monitoring: More consistent results for warpy filaments.

- Camera with Obico: Fewer wasted spools and better sleep.

- Air filtration: Better indoor experience, plus common sense ventilation.

- Open source: Freedom to upgrade and the comfort of community support.

- 6x6x6 in volume: A practical footprint that maximizes throughput for everyday parts.

The Moment I Knew It Would Stay on My Bench

It wasn’t the first print or even the first week. It was a long Saturday where I ran four different jobs—PLA, PETG-CF, ASA, and TPU—each with different profiles and goals. Not a single print failed. The camera caught a tiny adhesion hitch early on, and I stopped and restarted without sacrifice. At the end of the day, I had a tidy stack of finished parts and a clean conscience.

That feeling—productive without feeling punished—is why this machine stayed.

A Simple Checklist for Consistent Success

When I want to guarantee a good print, I run this quick mental list:

- Is the filament dry?

- Is the slicer profile matched to the material?

- Do I really need to push speed on the outer walls?

- Has the bed mesh been updated recently?

- Are the rails lightly lubricated?

- Is ventilation on if I’m using high-temp materials?

I rarely deviate. I also rarely regret it.

Things I Still Want

I want the chamber heater add-on. I’d also love official abrasive-resistant nozzle options in the box, even if as an upsell. And a few more pre-tuned slicer profiles for exotic filaments would make life easier for people who think retraction tuning sounds like a medical procedure.

None of these are deal breakers; they’re more like birthday wish-list items for a machine that already hits the essentials.

Final Verdict: Speed Meets Sense, and I’m Keeping It

The Sovol Zero 3D Printer, 1200mm/s High Speed CoreXY 3D Printers with Eddy Scanning & Pressure Sensing, 350℃ Nozzle & 120℃ Heated Bed Heating, XYZ Full Linear Rails Open Source Build Volume 6X6X6in delivers on the promise of speed without treating quality like a quaint old custom. The auto-leveling is genuinely next-gen, the thermal system opens doors to advanced filaments, the rails and damping keep motion dignified, and the camera and filtration make day-to-day use feel considered.

I’ve printed more in less time and with fewer arguments. I kept my space comfortable, my lungs unannoyed, and my parts satisfying to hold. If your projects live within a 6-inch cube and your ambitions include both pace and polish, this printer feels like the right kind of overachiever—fast, precise, and gracious about it.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.