Have you ever been curious about the world of 3D printing and found yourself at the fork in the road between resin and FDM 3D printers, wondering which path to take? I certainly found myself there, contemplating the mechanics and magic behind both types. It’s a bit like choosing between digital and film in photography; each has its own unique charm, challenges, and potential for creativity. Let’s wander down this road together and see where it leads us.

What Exactly are Resin and FDM 3D Printers?

Understanding the Basics

Before diving into the nitty-gritty, let’s take a step back and explore what makes these two types of 3D printers tick. Resin printers use a liquid resin that hardens when exposed to ultraviolet (UV) light. It’s a bit like setting your gelatin dessert under a sunlamp, only slightly more high-tech and expensive. FDM, which stands for Fused Deposition Modeling, involves thermoplastic filament being heated up and extruded layer by layer. Imagine a very precise, robotic icing artist creating a cake layer after layer, but instead of frosting, it uses plastic.

A Quick Comparison to Get Us Started

Here’s a quick table to vividly highlight some of the key differences:

| Feature | Resin 3D Printers | FDM 3D Printers |

|---|---|---|

| Material | Liquid resin | Thermoplastic filament |

| Finish | High-detail and smooth surfaces | Layered appearance with visible lines |

| Precision | High precision and detail | Moderate precision |

| Cost | Typically more expensive materials | Generally cheaper materials |

| Setup & Maintenance | More complex and messier | Simpler and cleaner |

Diving Deeper into Resin 3D Printers

Why Choose Resin?

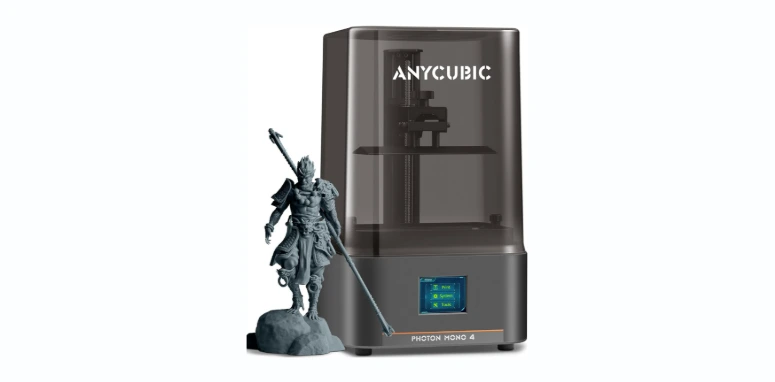

Resin printers are for those of us who are a bit of perfectionists obsessed with detail. When it comes to creating intricate designs, resin printers outperform FDM printers with their ability to articulate fine details and smooth surfaces. Think of producing miniature figures or jewelry that require exquisite attention to detail and a smooth, polished finish.

Challenges With Resin

If you’re anything like me, handling substances can be a bit of an adventure. Resin requires careful handling because of its chemicals, meaning gloves and a well-ventilated workspace become your best friends. It can be a bit like handling hazardous materials while wearing a fancy ball gown—the stakes feel pretty high.

Costs Involved

Operating a resin 3D printer often invites a parade of costs. The resin itself isn’t cheap, and you’ll need to replenish it with some regularity, like those little indoor fountains that are charming until you realize how often they need refilling. Additionally, there’s the cost of meticulously cleaning and maintaining the printer, which is a price you pay for the stunning quality of your prints.

FDM 3D Printers: An Uncomplicated Workhorse

The Allure of FDM

FDM printers are for those who lean towards the practical side of creation, thriving on simplicity and accessibility. It’s the practicality of printing larger objects that draws me in, like the idea of printing out a sturdy, custom suit of armor for my pet tortoise or a quirky bookshelf to add to my cluttered study.

Easier to Use?

Yes, operating an FDM printer can feel more straightforward. Load in the filament like threading an old sewing machine with surprisingly less finesse needed, and you’re off. Their setup isn’t quite like wrangling a wild animal, which is always a plus.

Costs Friendly?

Oftentimes, FDM printers and their material, the ubiquitous PLA or ABS filament, tend to be more budget-friendly. While you may not be crafting intricate jewelry, the savings give you the freedom to engage in big, bold projects without emptying your wallet. Think of it as the bulk-printing value pack option.

The Quality Battle: Precision and Finish

Surface Finish: Gliding Through Details

If it’s that ceramic smooth touch over a sandstone grit you’re after, resin is the go-to choice. For those beautiful, smooth surfaces where detail is paramount, resin delivers every time. However, if the signs of the layers are part of the charm and character you seek, FDM has its allure. There’s an almost nostalgic satisfaction in seeing the layers like strokes in a painting.

Precision: The Devil’s in the Details

When detail becomes the leading actor on your 3D printing stage, resin once again proves its superiority. Its high-definition precision allows for strikingly intricate designs, turning ambitious concepts like detailed architectural models or tiny mechanical parts into realities.

However, perhaps you’re more into creating abstract art pieces or utilitarian items where slight imperfections become part of the story. In those moments, FDM printers tell a tale all their own, with a reliability that’s somewhat reassuring—like an old car that puffs a bit of smoke but always starts in the morning.

Application-Specific Preferences

Versatile Resin Applications

For jewelry-makers, model enthusiasts, or those in professions needful of prototyping with intricate details, resin 3D printers are often the preferred choice. The ability to capture tiny movements and delicate structures makes it a spellbinding tool in these fields.

FDM’s Broader Utility

FDM printers lend themselves well to larger-scale projects; their breadth of utility spans creating functional parts, practical prototypes, and household items. If you’re a DIY enthusiast, or someone who finds joy in crafting and rearranging their living space with custom prints, you could find a good friend in the FDM printer.

Maintenance and Safety Concerns

Watching Over Resin

Operating a resin printer means regularly engaging in a spa-like ritual of cleaning and curing your prints. Let’s not forget the importance of setting aside a specific portion of your space to avoid unwanted drips and spills. Safety is paramount since resin can be toxic, necessitating the use of appropriate gear. It’s like hosting a safety-conscious guest who’s very particular about their personal space.

FDM’s User-Friendly Approach

Maintaining an FDM printer, by contrast, involves far less regimented rituals. While you won’t need to perform safety dances with gloves and masks—though imagining it does offer a delightfully comedic vision—you’ll still need to keep an eye on nozzle clogs and layer adhesion issues. The effort here is somewhat pleasant and straightforward, akin to keeping a bicycle well-oiled and road-ready.

Speed and Efficiency

The Tortoise and the Hare Analogy

Resin printers sometimes feel like the tortoise in the ongoing comedy that is speed. The high detail and precision can slow down the printing process, but if time isn’t your chief concern, the output quality speaks for itself.

FDM printers are more the hare in this race. They’re typically quicker, cranking out larger and more crude objects at a decent pace, which is hugely beneficial if you’re shooting for neither micro precision nor a lengthy wait time.

Environmental Considerations

Eco-Friendly Choices

If your heart beats for the earth, considerations about filament biodegradability or resin’s disposal methods will weigh heavy on your conscience. PLA filament from FDM printers often comes out as the more eco-friendly option as it’s plant-based and compostable. It’s a greener choice in a field bustling with otherwise impactful waste.

Resin, albeit newer formulations claim to be more environmentally friendly, still struggles to match the biodegradability of PLA filament. It’s a bit like comparing an artisanal organic soap to one crafted entirely out of non-recyclable materials.

The Final Decision: Which to Choose?

Consider Your Needs

When I think about 3D printers, it’s apparent that the choice lies heavily upon the type of project one aims to undertake. If you’re detail-oriented, preferring smaller, more intricate creations, resin might be your muse. But if you’re after larger items, prototyping a new invention, or simply starting out with fewer headaches, you’ll find a solid partner in FDM printers.

Budgetary Concerns

Budget, too, plays a significant role—your financial reality will guide whether a resin printer becomes a viable luxury or an FDM printer a practical companion. It’s much like settling on a dining choice between a high-end restaurant and a beloved local diner, each promising joy in different measures.

Personal Preferences

At the end of the day, it’s about the personal narrative each printer type writes for you. Whether your focus is finesse or function, both resin and FDM printers have compelling stories to tell, ready to etch them into the medium of your choice.

As you stand at your own fork in the road, armed with this understanding and unraveling of choices, the decision seems less daunting. Whether resin or FDM, the journey into 3D printing awaits to welcome you to explore, create, and innovate in ways uniquely yours.