Have you ever watched a tiny cathedral rise out of goo and thought, “This could be faster?”

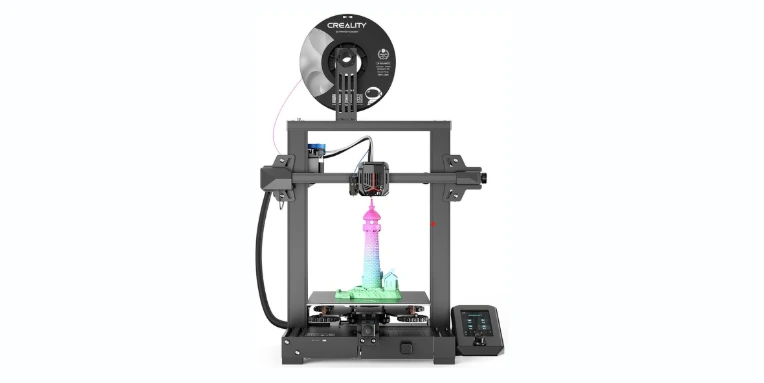

My Hands-On Review of the ELEGOO Mars 5 Ultra 9K MSLA Resin 3D Printer

I brought home the ELEGOO Mars 5 Ultra 9K MSLA Resin 3D Printer because impatience is my love language. I’ve stood over too many resin vats at midnight, willing layer 427 to materialize before I aged into a different demographic. On paper, this machine promises speed—up to 150 mm/h—plus brains, with a mechanical sensor and an AI camera that watches prints like a hawk with a computer science degree. I set it up, spilled a little resin (it’s part of my ritual), and settled in to see if this really was the tidy, fast, smart printer it claims to be.

The short version is that I’m impressed—and mildly annoyed that this didn’t exist earlier. The long version is below, where I get into the quirks, the delight, and the occasional “Is the machine scolding me?” feeling I got from the Mars 5 Ultra’s sensor-and-camera tag team.

ELEGOO Mars 5 Ultra 9K MSLA Resin 3D Printer, Smart Mechanical Sensor, Fast Printing Up to 150mm/h, AI Camera, WiFi Cluster Printing, Automatic Leveling, Large Printing Size 6.04 * 3.06 * 6.49 inch

$284.88 In Stock

What This Printer Is, in Practical Terms

The official name is a mouthful: ELEGOO Mars 5 Ultra 9K MSLA Resin 3D Printer, Smart Mechanical Sensor, Fast Printing Up to 150mm/h, AI Camera, WiFi Cluster Printing, Automatic Leveling, Large Printing Size 6.04 × 3.06 × 6.49 inch. In regular human language, it’s a compact, high-resolution resin printer designed to print fast while keeping quality, with extra smarts to prevent the tiny tragedies that used to ruin entire weekends.

What Stood Out to Me First

- It prints noticeably faster than earlier-generation resin machines thanks to a Tilt Release system that un-sticks layers more efficiently.

- A built-in smart mechanical sensor handles one-click calibration and watches for low resin, foreign objects, or overheating.

- An AI camera peers into the build area to catch things like an empty build plate or a curling model, and it can produce time-lapse videos.

- I can send prints over WiFi (2.4G/5G), skip USB sticks entirely, and even run multiple Mars 5 Ultras at once on the same network.

- The 9K mono LCD (8520 × 4320) and 18 × 18 μm XY resolution, plus 92% light uniformity from a COB light source, produce exceptionally crisp prints.

The Specs I Actually Care About

Here’s the information I found myself repeating to friends and anyone trapped near me in line at the art supply store. This is the “how it feels to use” list, not just what’s on the box.

Key Specs at a Glance

| Feature | What It Is | Why I Care |

|---|---|---|

| Printing Speed | Up to 150 mm/h (fast/slow modes) | Faster prints without turning model details into soup |

| Separation Method | Tilt Release Innovation | Reduces Z movement time; layers let go cleanly |

| XY Resolution | 18 × 18 μm | Crazy fine detail, especially on minis and jewelry |

| LCD Screen | 7-inch monochrome 9K (8520 × 4320) | High-resolution screen that cures fast and sharp |

| Light Source | Internal COB with 92% uniformity | Consistent curing across the whole build plate |

| Build Volume | 6.04 × 3.06 × 6.49 inches | Big enough for most minis, props, and small functional parts |

| Mechanical Sensor | One-click calibration, detects low resin/foreign objects/high light-board temp | Fewer failed prints, less guesswork |

| AI Camera | Detects empty build plates and warping; time-lapse | Saved me from silent fails and gave me shareable videos |

| Connectivity | WiFi (2.4G/5G), 6–10 Mbps; cluster printing; OTA firmware | File transfers without USB sticks, multi-printer control |

| User Interface | Capacitive touchscreen, vertical UI, 12 languages | Easy, pleasant to use; clear status info |

| Protective Glass | 9H tempered glass over LCD | Peace of mind against drips and accidental nicks |

| Resin Management | Dual pour spouts; replaceable resin tank lock screw | Less mess when pouring and maintenance |

| Build Plate | One-touch locking; laser-engraved surface | Reliable adhesion and simple plate swapping |

| Print Continuation | Resumes after interruptions | Power flicker? I didn’t lose the whole model |

Setting It Up: From Box to First Print

I opened the box and found a machine that’s clearly designed by people who’ve done the resin shuffle at 2 a.m.—that dance where you try not to splash polymer on your socks while adjusting a build plate. The Mars 5 Ultra cuts down on minutes spent fiddling before I even pour resin.

Hardware Setup and Calibration

I attached the build plate, dropped in the resin tank, and pressed the single-button calibration. The smart mechanical sensor and spring took care of leveling. It feels almost suspicious at first—my inner drama queen is used to screwing down corners and wobbling paper under the plate. Here, I just hit a button, and it sets itself. I didn’t argue.

The one-touch build plate locking is instant and reassuring. No half-hearted tightening, no second-guessing. When I say “locked,” I mean it; if I had a dollar for every time a plate slipped mid-print on older machines, I’d have enough to buy a second Mars 5 Ultra and a latte.

Firmware and WiFi Setup

I connected to my 5G network, entered the password, and let the printer pair with my laptop. File transfers moved at a snappy 6–10 Mbps, which sounds quaint if you’re streaming a movie but is perfectly delightful when you’re pushing sliced print files. No USB stick, no scavenger hunt behind the couch.

OTA firmware updates showed up as a tidy prompt on the screen. I let the machine handle itself, and it did, like an adult.

Resin Calibration and First Layers

Before my first “real” model, I used the resin calibration to dial in exposure. It’s the difference between getting crisp edges on a model or watching details blur like a watercolor left out in the rain. The calibration process nudges the exposure time to suit your resin, which means fewer rookie mistakes even when you’re not a rookie.

When I printed a test bust for scale, the first layers stuck solidly to the laser-engraved build plate, and the Tilt Release action quietly worked in the background. The Z-axis didn’t skyrocket after each layer like a theater curtain—it followed a smoother rhythm that clearly conserved time.

The Speed: What 150 mm/h Actually Feels Like

On pure speed, there’s a difference you feel. Fast mode on a resin printer is like having the bakery tell you that yes, the croissants will be ready in five minutes. Not every model should be rushed (more on that), but when I printed a tray of small tabletop miniatures, the Mars 5 Ultra flew through them. I didn’t need to baby-sit every layer like a neurotic plant parent.

The Tilt Release Innovation is the unsung hero here. By easing the part off the vat with less movement and stress, it shortens the Z travel, which is the slowest part of resin prints. On batch jobs with multiple small pieces, the time savings compound like interest.

Fast vs Slow Mode in Real Life

- Fast Mode: I used this when I needed a quick copy of something fairly forgiving—mini bases, terrain slabs, brackets, a prototype hinge. The surface finish remained clean, and details survived just fine.

- Slow Mode: I switched to slow for intricate busts, jewelry-scale features, and parts where micro-detail mattered more than getting it done before my next coffee. It’s nice to choose speed or perfection instead of being trapped in one lane.

And no, fast mode didn’t produce a spaghetti monster. The light uniformity and 9K panel kept edges clean even when I got greedy with speed. I only stepped back to slow mode for filigree-level detail—or when I crammed the plate with too many parts like an overstuffed suitcase.

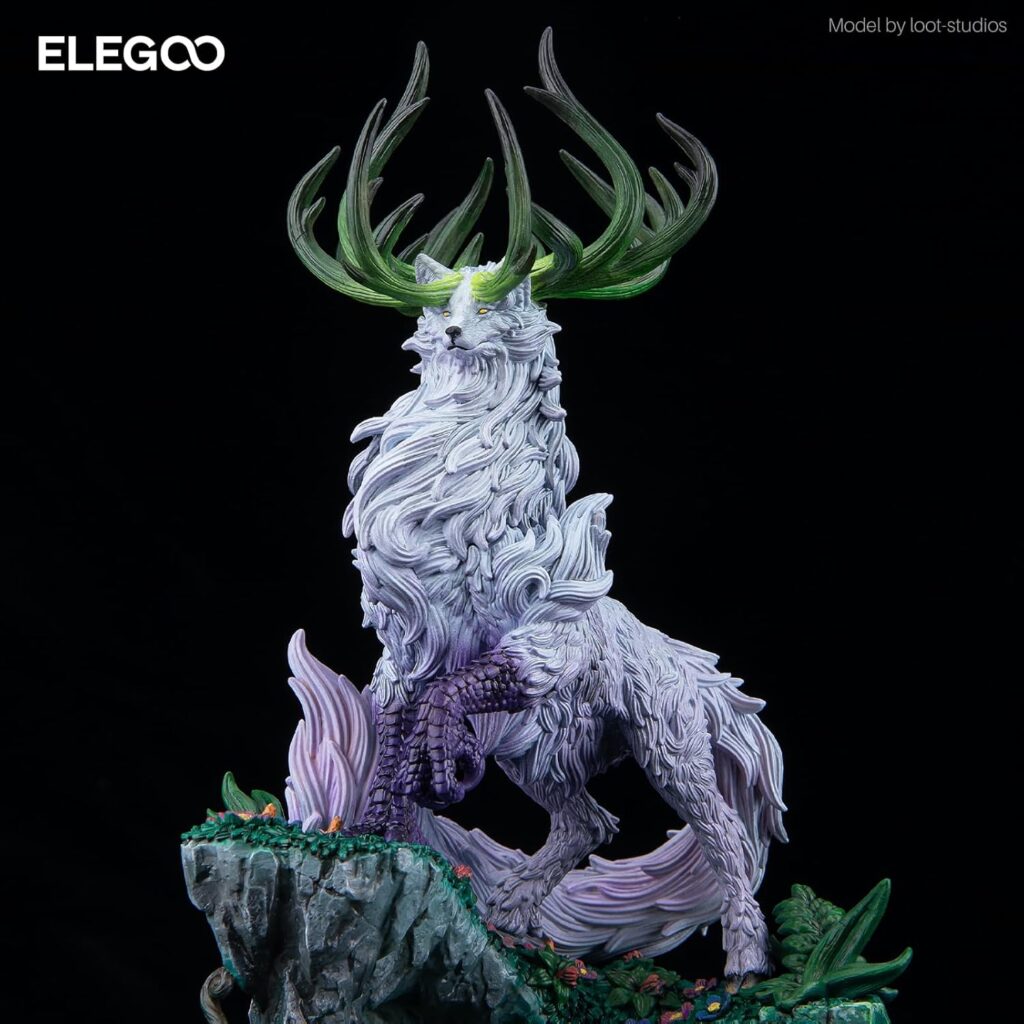

Image Quality: The 9K Factor and Light Uniformity

If resolution were a person, it would be the quiet, clever friend who sits in the corner and makes everyone else seem loud. The Mars 5 Ultra’s 7-inch 9K mono screen (8520 × 4320) with an 18 × 18 μm XY resolution brings out fine lines that older 2K or 4K machines simply blur. Combined with 92% light uniformity from the COB light source, it produces edges that make me feel a little smug—like I knew what I was doing all along.

Real-World Details I Noticed

- Hard edges and small type on a scale nameplate printed legibly without looking like a gummy bear.

- Hairline textures on a 32 mm miniature face actually showed up in the paint stage; I wasn’t faking it with a brush anymore.

- Curves looked smooth instead of stair-stepped, particularly on armor plates and gem-like surfaces.

The 9H tempered glass protecting the screen made me bold when I accidentally bumped the vat mid-pour. I don’t recommend improvisational resin acrobatics, but it’s comforting knowing there’s a protective barrier.

The Smart Stuff: AI Camera and Mechanical Sensor

This is where the Mars 5 Ultra feels like a printer that’s trying to prevent me from doing something regrettable. The mechanical sensor and AI camera play parent and guidance counselor. They don’t nag; they just step in when I’m about to turn a minor mistake into a full-blown mess.

The Mechanical Sensor: The Practical Hall Monitor

The built-in smart mechanical sensor does two things brilliantly: one-click calibration and adult supervision. It detects:

- Low resin: No more printing happily into thin air and realizing later why the model is missing a torso.

- Foreign objects: That extra support raft I dropped into the vat? It noticed.

- High light-board temperature: If things are heating up too much, it alerts me so I don’t shorten the lifespan of the printer or the resin.

I’ve had prints pause and then resume without drama after an interruption. The continuity is huge. Before this, a power blip could ruin hours of work. Now I get a notification, the machine catches its breath, and then carries on.

The AI Camera: Extra Eyes and Time-Lapse Candy

The AI camera checks for:

- Empty build plate: When there’s nothing sticking after those first layers, it doesn’t pretend everything is fine. It nudges me to intervene before I waste resin.

- Warp detection: If a model starts peeling up or twisting, the camera notices and lets me know.

The time-lapse feature is my guilty pleasure. I can record prints and then show them off to friends who pretend to be interested. It’s also useful for diagnosing what went wrong when something fails: the moment a corner lifts off, it’s right there in the footage.

WiFi, Cluster Printing, and OTA: My New Workflow

I used to shuffle USB sticks back and forth and wonder whether file transfer was secretly where I lost my will to print. WiFi on the Mars 5 Ultra solves that, and not by asking me to accept janky software. I send files wirelessly, monitor jobs, and, yes, I can run multiple Mars 5 Ultras in a cluster on the same LAN. For batch printing, this is a dream.

Multi-Printer Nirvana

If you’ve ever run more than one resin printer, you know the dance of “which one is doing what.” With cluster printing, I send the same file to multiple machines and have identical parts finishing at the same time. It’s efficient and strangely satisfying—like synchronized swimming, if the swimmers were made of plastic.

OTA firmware updates keep things current without downloading files from a forum. I pressed update, took a sip of tea, and it was done.

Design and Ergonomics: The Mess-Fighting Details

Resin printing will always be a little messy, like cooking with chocolate or painting with a cat in the room. But this machine chips away at the fussiness.

- One-touch build plate locking: Snap, done. Confidence in a single gesture.

- Laser-engraved platform: Prints cling in the right way; first-layer adhesion feels more predictable.

- Dual pour spouts: I can empty the vat without creating a resin waterfall across the bench.

- Replaceable resin tank lock screw: A small thing until it’s not. Nice to know this is easily swapped.

- Capacitive touchscreen with a vertical UI: Feels modern, responsive, and easy to navigate without stabbing at it like you’re trying to win a carnival game.

- 12 language support: Not a factor for me personally, but it’s considerate, and I appreciate considerate machines.

The overall footprint fits comfortably on a small workbench. I chose to add ventilation and keep it near a window because resin is still resin, and I like my lungs the way they are.

Day-to-Day Use: My Printing Routine

Here’s how I’ve come to run prints with the Mars 5 Ultra. If I had to put it into a recipe card, it would go like this:

- Check the vat for leftovers and foreign objects. The sensor will scold me later if I don’t.

- Run resin calibration the first time with a new bottle. It takes a minute and saves me hours.

- Load files over WiFi. No more “where did my USB go?” scavenger hunts.

- Choose fast or slow mode based on the model. Are we making functional parts or heirlooms?

- Use the AI camera’s live view to watch first layers. If the build plate is empty, I know immediately.

- Let prints run. Time-lapses save little victories for posterity.

- When finished, drain via the dual spouts, clean the vat, and wipe the build plate.

- Post-process the print: IPA wash, gentle brush, cure under UV, and finish as needed.

This routine keeps the machine humming and my mood unruffled.

Print Quality: How Fussy Can I Get?

Very, apparently. The 18 × 18 μm XY resolution combines with that 9K screen to make small textures readable. I tested it with models that had fine art deco lines and armor seams thinner than a whisper. In slow mode, the Mars 5 Ultra captured them faithfully. In fast mode, read the room: it still looks great, but if you’re chasing micro details for casting masters, slow mode is the safer bet.

Supports detach cleanly, and the laser-engraved plate reduces those terrifying first-layer “do I stick or do I leave?” moments. I haven’t had to reprint first layers as often, which feels like cheating, only it’s not.

Resin Calibration: Hitting the Sweet Spot

The resin calibration feature is the adult in the room we didn’t know we needed. Resin formulations vary—some thicker, some more opaque. Instead of pretending they’re all the same, the printer helps dial in exposure. I’m a reformed tinkerer; I’ll tweak settings when I want to, not because I have to. The calibration made most of my prints more “push button, receive part” than I care to admit.

If you switch resins often (contrasting colors, flexible versus standard), calibration keeps results consistent. It doesn’t take long, and the payoff is immediate.

Reliability, Safety, and Maintenance

Reliability is sexy, even if it doesn’t look good on Instagram. Here’s what kept me happy during longer sessions.

- Sensor checks mean fewer horror stories. The foreign object detection saved one of my vats from a nasty scratch.

- Temperature monitoring protects the light board. Electronics like moderate climate; the printer helps enforce it.

- 9H tempered glass guards the LCD. Less risk means I’m less anxious about carefully removing the vat like a bomb technician.

- Replaceable parts like the resin tank lock screw make it maintainable on a reasonable timeline.

- Alerts and print resumption reduce wasted resin and time.

For maintenance, I keep a small ritual:

- Wipe the build plate after each print; keep it dry.

- Filter resin back into the bottle with a fine mesh when switching.

- Inspect the FEP/nFEP film (the vat film) for wear; replace when cloudy or scratched.

- Run a quick screen test once in a while to ensure no dead pixels.

- Update firmware when prompted.

It’s hard to overstate how much the sensors reduce risk. If you’ve had a bracket come loose and smear itself into a resin omelet, you’ll appreciate the Mars 5 Ultra’s willingness to pipe up.

Noise, Smell, and Footprint

The printer itself is quiet—mostly Z-axis sounds and fan noise. The smell depends on your resin and ventilation. I use a ventilated area and a covered cure station to keep the olfactory presence minimal. If you’re in a small room, crack a window and consider a carbon filter nearby. My goal is to print, not scent the house like a chemistry set.

The footprint is compact for what it does. The build volume of 6.04 × 3.06 × 6.49 inches fits most of my projects, and the machine doesn’t demand a shrine—just a stable table and some patience.

WiFi Cluster Printing: When One Job Isn’t Enough

If your workflow involves batches—army units, jewelry blanks, repeat parts—cluster printing on the same LAN is a gift. I sent the same file to multiple printers and had matching sets ready together. It reduces that awkward waiting period where one printer is done and the others are mocking it from across the room.

Remote control and secure, fast data transfer mean I’m not constantly hovering. I still check the AI camera occasionally because I’m nosy, but the days of panicked running when I hear a strange sound are fewer.

Where It Fits: Beginners, Pros, and Everyone Between

- If you’re new to resin printing: The one-click calibration, AI camera, and mechanical sensor are training wheels you don’t have to be embarrassed about. You can learn while you print without sabotaging yourself.

- If you run a small studio or side business: Speed, consistency, and cluster printing matter. The Mars 5 Ultra can be the dependable workhorse you add for throughput.

- If you’re a detail obsessive: The 9K screen and 18 μm XY resolution will feed your need for texture and crispness.

I’ve used it for tabletop minis, functional snaps, accessories for costumes, and hobby projects that probably didn’t need to exist but now live on my shelf and judge me. The printer handled all of them without complaint.

When Not to Use Fast Mode

Fast is wonderful, but like espresso after 5 p.m., there’s a time and place. I switch to slow when:

- The model has intricate relief and tiny text.

- I’m using a resin that behaves better with longer exposures.

- I’m packing the build plate wall-to-wall.

- I’m making masters that will be cast or molded.

If you’re not sure, print one version in fast and one in slow. The time difference might surprise you, and your eyes will tell you which one to keep.

Troubleshooting Tips I Learned the Friendly Way

- Empty build plate detected: Stop, clean the plate, check for residue on the film, recalibrate the plate. Re-slice with a 0.05 mm thicker first layer if it keeps happening.

- Warping mid-print: Add bracing supports or a brim, reorient the model to reduce suction, and slow the lift speed slightly if you’ve gotten overly bold.

- Low resin alert: Top up. Don’t trust your eyeballing skills at 11 p.m. Resin is deceptive in low light.

- High light-board temperature: Let it cool down, improve airflow around the machine, and consider reducing ambient heat in the room.

- Foreign object detected: Filter your resin, check the vat film, and take a breath. The printer just saved you from something worse.

Slicer and File Workflow

I prefer slicing on my computer because I like a big screen and a cup of tea beside me. Then I send the file over WiFi to the Mars 5 Ultra. It’s painless. If you’re team USB, it works too, but once you’ve gone wireless, it’s hard to go back.

For supports, I use conservative settings on delicate parts and heavier tree supports on tall, thin shapes. The Mars 5 Ultra’s precision means you can get away with finer supports than older models, but don’t get too stingy—gravity hasn’t changed.

Miniatures, Props, and Practical Prints

- Miniatures: Excellent. Detail on faces, belts, and cloth textures comes through. Paint adheres nicely after the usual wash and cure.

- Props and costume bits: Buckles, clasps, faux metal parts—fast mode is plenty for these. For plates that will be handled often, I’ll use a more robust resin and post-cure thoroughly.

- Practical household bits: Replacement knobs and clips print strong if oriented with stress in mind. I use chunky supports and slow mode for those, because function beats fashion.

Pros and Cons After Real Use

Here’s the part where I admit what I loved and what had me muttering under my breath.

What I Loved

- Tangible speed gains without turning prints brittle or sloppy

- The AI camera that catches empty plates and warps before I waste hours

- The mechanical sensor’s one-click calibration and sanity-saving alerts

- WiFi with cluster printing that simplifies multi-printer setups

- 9K LCD and 18 μm XY resolution for crisp edges and tiny details

- 92% light uniformity—corners look as good as the center

- Protective 9H glass that helps me relax around the vat

- Thoughtful design: dual pour spouts, laser-engraved plate, replaceable lock screw

- OTA firmware updates that just work

What I Didn’t

- Fast mode is powerful, but not a universal solution—intricate models still want slow mode

- Resin management is still resin management; you’ll need ventilation, gloves, patience

- Time-lapse enabled me to watch my own mistakes with cinematic flair (useful, but humbling)

None of these are dealbreakers; they’re just the reality of resin printing with a very competent machine.

Questions I Asked Before Buying (And Answered Myself)

- Do I still need to level? The one-click calibration via the mechanical sensor is the leveling. It works reliably, and I’m not nostalgic for the old paper shuffle.

- How fast is “fast” in real terms? Up to 150 mm/h as advertised, with real-world gains that felt meaningful. Batch jobs benefited the most.

- Is the AI camera just a gimmick? Not here. It caught two issues early for me: an empty plate and a curling support.

- How stable is the WiFi? Solid on both 2.4G and 5G in my setup. File transfers at 6–10 Mbps were consistent.

- Will the screen survive my clumsiness? The 9H tempered glass is robust. I still handle it carefully, but I’m much less anxious.

Safety and Best Practices

- Gloves, always. Resin doesn’t care how careful you think you are.

- Ventilation. A simple window or a small fume extractor helps a lot.

- Avoid pouring resin over electronics or LCD edges. The dual spouts help control flow.

- Keep IPA away from the printer’s plastic parts; use it on the print and plate, not the machine body.

- Cure prints thoroughly to finish off any tackiness and stabilize them.

I also keep a small spill kit—paper towels, resin-safe wipes, a silicone mat. If you work clean, you work happy.

Who Will Get the Most Out of This?

- Tabletop gamers who batch-print minis and terrain: Speed and detail in one box.

- Makers and cosplayers: Functional parts with a nice surface finish.

- Jewelry designers and miniature sculptors: Resolution that does your work justice.

- Small studios: Cluster printing for throughput, sensors for reliability, WiFi for sanity.

If you’re allergic to tinkering or too busy to babysit, the sensors and camera feel like a quiet assistant. If you love tuning, the calibration tools are there without getting in your way.

Living With It: A Week, A Month, and Counting

In the first week, I tried to break it with carelessness (not on purpose, exactly). The Mars 5 Ultra debated me by simply working. In the first month, it became the machine I turned to first because it took the least coaxing to produce clean parts.

I got braver with my print plate layouts, and the AI camera earned its keep by catching one sloppy support structure before it became a catastrophe. The mechanical sensor and its heat warnings made me feel like I had a colleague who was watching the environment when I wasn’t.

A Few Print Scenarios That Won Me Over

- A tray of six 32 mm figures in fast mode: crisp enough to paint straight after wash and cure, done before lunch.

- A jewelry master with filigree in slow mode: the lines survived casting—and my perfectionism.

- Replacement drawer clip: oriented for strength, cured thoroughly, and it’s still intact after weeks of daily use.

None of these are headline-grabbing prints, but that’s sort of the point. The Mars 5 Ultra turned them into ordinary successes. I like ordinary successes.

The Intangibles: How It Feels to Own

Owning a resin printer used to mean signing up for a second job. The Mars 5 Ultra feels more like a reliable appliance with a quirky personality—alert, watchful, and occasionally judgmental with its AI camera, but always on my side. I don’t have to pretend to enjoy troubleshooting; I do it when I want to understand, not when I’m backed into a corner.

There’s joy in a tool that gets out of your way. This one does, most of the time, with occasional small theatrics when it politely informs you that you forgot the resin. We all need a friend like that.

Summary: What I’d Tell a Friend in One Breath

It’s fast when you need speed, precise when you need detail, and designed to keep you from making the kind of mistakes that cost resin, time, and patience. The 9K screen and 18 μm XY resolution make prints look stellar; the Tilt Release saves time; the mechanical sensor and AI camera catch issues early; WiFi and cluster printing turn workflow into something sensible; and the user-friendly touches reduce mess and friction.

Final Verdict

I’d buy the ELEGOO Mars 5 Ultra 9K MSLA Resin 3D Printer again without blinking. It makes resin printing feel less like a high-maintenance hobby and more like a dependable creative process. The speed is real, the quality holds up, and the smart features earn their name. If you’re ready to print more and fuss less, this is a strong, easy yes from me.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.