Have you ever watched a printer on your desk and thought, “If only you moved like a caffeinated cheetah with the manners of a Swiss watch”?

Why I Bought the Sovol Zero 3D Printer

I’ve owned enough 3D printers to know that speed promises are often like crash diets: impressive headlines, questionable follow-through. When I read “Sovol Zero 3D Printer, 1200mm/s High Speed CoreXY 3D Printers with Eddy Scanning & Pressure Sensing, 350℃ Nozzle & 120℃ Heated Bed Heating, XYZ Full Linear Rails Open Source Build Volume 6X6X6in,” I felt equal parts skeptical and giddy. I told myself I’d be reasonable, methodical, and adult about it. Then I added it to cart like a raccoon who just discovered an unattended bag of kettle corn.

My Printing Background

I’ve printed everything from toy octopi to functional brackets to a failed chess set that looked like it had seen a ghost. I’m comfortable with slicers, calibration, and the occasional midnight battle with a clogged nozzle. I wanted something that respected my time, didn’t require a herd of mods to behave, and genuinely pushed the envelope without pushing me into a meltdown.

What Caught My Eye

Two things drew me in: 1200 mm/s speed claims and the auto-leveling V3.0 system with eddy current scanning plus pressure sensing. I also liked that it’s CoreXY, open source, and built on full linear rails. The pitch sounded like the printer equivalent of a high-performance hatchback—fast, clever, practical, and interesting enough that I’d want to talk about it at a dinner party, whether anyone asked or not.

Sovol Zero 3D Printer, 1200mm/s High Speed CoreXY 3D Printers with Eddy Scanning & Pressure Sensing, 350℃ Nozzle & 120℃ Heated Bed Heating, XYZ Full Linear Rails Open Source Build Volume 6X6X6in

Unboxing and First Impressions

When the Sovol Zero arrived, I expected a crowd of parts and small baggies that would shame my weekend plans. What I found instead was a well-organized, compact package that made the whole “fast but precise” thing feel believable. Even the foam seemed engineered with a purpose, which, for me, is like a handshake from the future.

Build Quality and Design

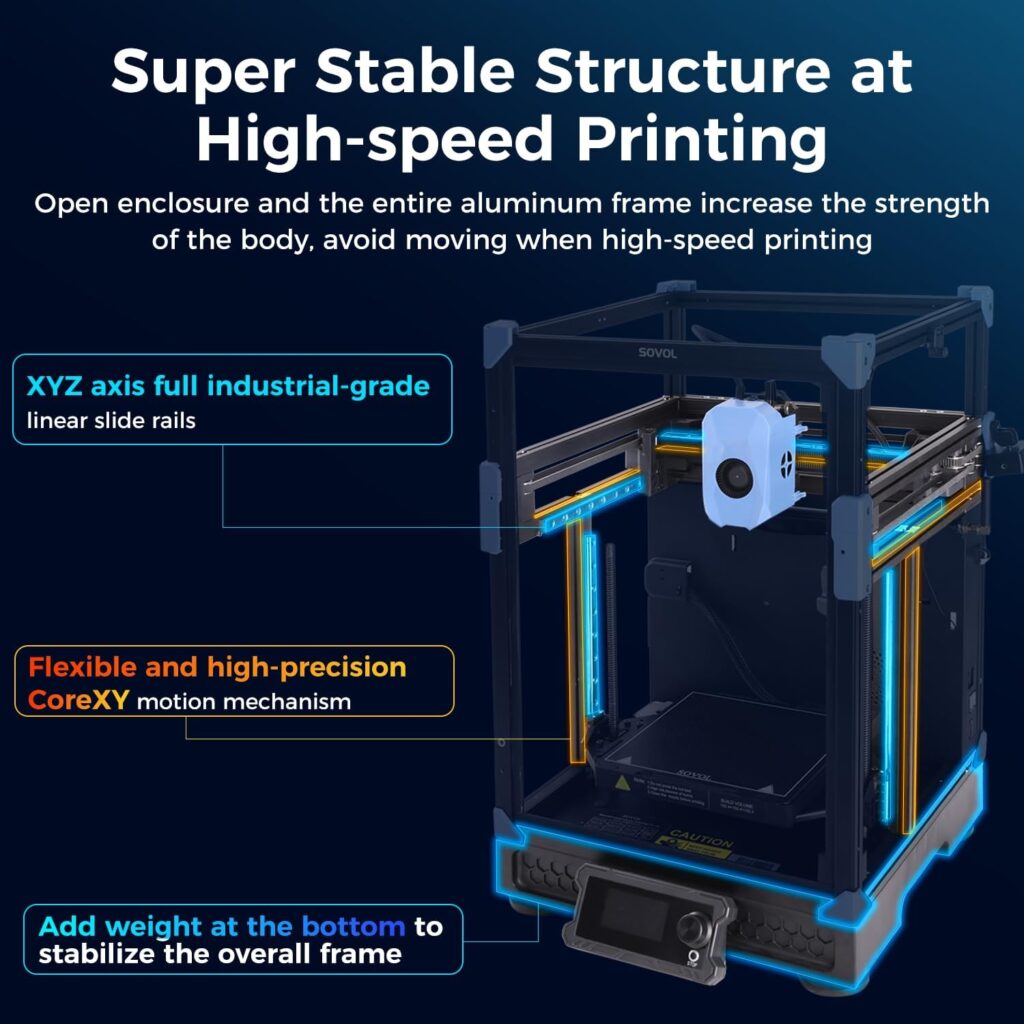

The Sovol Zero looks like it was assembled by someone who had a list and checked it twice. The CoreXY frame is rigid, the rails are actual linear rails on X, Y, and Z, and there’s a sober elegance to the motion system. It’s not a flashy machine, but it’s the kind of design that whispers, “I’ll be here long after your fashionable gadgets have moved to a drawer.”

What’s in the Box

Inside, I found the printer, a build plate, a hotend assembly, tools, spare parts, and the basics you need to get started. There’s a built-in camera, air filtration system, and a nicely thought-out cable routing scheme, which meant I didn’t have to pretend I enjoy zip ties as much as the internet thinks I should. It felt like Sovol considered not just the parts, but my eventual sanity.

Setup and Assembly

Assembly is straightforward, with fewer steps than I expected given the feature list. It’s not a Lego set, but it’s also not a “clear your weekend and warn your family” project. Once I squared the frame and checked the belts, the machine felt ready—like it had been waiting for me to stop fussing and start printing.

Mechanical Assembly and Build Plate

Belts were pre-tensioned, but I still checked them because I am that person. The build plate seats well, and the bed itself is an AC heated design, which heats faster than the “wait three minutes and wonder if it’s broken” DC beds I’ve owned. There’s an overheating protection feature that made me feel like someone at Sovol has met me and my tendency to forget the printer mid-print while making tea.

Firmware and Software

The printer plays nicely with open-source slicers, and Sovol provides profiles that get you moving quickly. I tweaked speed and acceleration gradually, the way you coax a cat onto a new sofa. The firmware gives you granular control and still feels accessible. If you want to tinker, it encourages you. If you don’t, it politely steps aside and lets you print in peace.

Auto-Leveling V3.0: Eddy Scanning + Pressure Sensing

This is the part that made me feel like I was holding the remote to a spaceship. The eddy current sensor maps the bed without touching it, using magnetic induction to gather data quickly. Then the pressure sensor gently finds the precise contact point, as if it’s saying, “Allow me to confirm, just so we’re both sure.” The result is a fuss-free first layer that I didn’t have to cross my fingers about.

CoreXY Done Right

CoreXY isn’t just a buzzword here; it’s the spine of the experience. With fewer moving parts and a compact motion system, it really does move like it means business. Acceleration isn’t just a number—it’s something you feel in your bones when the head starts drawing circles like it’s late for a flight.

Full Linear Rails on XYZ

I’ve used rods and wheels that were new and promising and then, after a few months, got tired and squeaky like old hardwood floors. Here, the linear rails make motion consistent and silky, with fewer artifacts on fast prints. They feel like an investment in sanity, particularly if you value repeatability more than you value excuses.

Silicone Damping and High-Speed Stability

High-speed printing can make even the best machines shake like a chihuahua holding a latte. The silicone damping pads absorb the worst of it, keeping the printer stable and producing visibly cleaner high-speed output. It doesn’t replace good slicer settings, but it certainly gives them a better stage to perform on.

Speed Claims vs Reality

Printing at 1200 mm/s is not something you do all the time unless you enjoy chaos or test cubes. But the Sovol Zero’s acceleration and overall system efficiency make meaningful speed gains even at more practical speeds. I ran benchmarks at 300–500 mm/s that looked better than what I used to get at 80–120 mm/s on older bedslingers, which is like discovering your slow cooker is actually a pressure cooker in disguise.

The “Fast Enough” Zone

For me, the sweet spot was around 300–400 mm/s for aesthetically decent parts and 500+ mm/s for functional or draft prints. I was impressed with how well the corners held together and how minimal the ringing was. It’s the first printer where I didn’t feel like I had to explain away speed with a sigh and a shrug.

CoreXY Payoff in Real Prints

Small parts with intricate patterns or thin walls benefitted the most. The motion system keeps them sharp without the wobble that shows up when inertia becomes a co-author in your work. I felt more confident throwing ambitious timelines at parts that used to be weekend projects.

Print Quality

Speed is exciting, but quality is what you live with. The Sovol Zero lands a first layer with the nonchalance of a seasoned baker sliding a loaf into the oven. Once that’s in place, the layers stack tidy and consistent, which is half the battle in any print.

First Layer Performance

With eddy current scanning and pressure sensing working together, I rarely touched manual adjustments. The Z compensation grid was accurate across the bed, and my first layers had that nice, even sheen that says, “All is well in the world.” It made running multi-hour prints feel much less like an act of faith.

Surface Finish and Artifacts

At moderate speeds, the finish was crisp, with minimal ghosting. At higher speeds, you’ll see some texture—but less than I expected. In fact, I used textured layer lines as a stylistic choice on a few functional parts, like little speed stripes to remind me I didn’t spend my evening waiting for a bracket to exist.

Dimensional Accuracy

I printed calibration cubes, functional hinges, and snap-fit parts, and the tolerances were consistent. With minor adjustment on flow and horizontal expansion, I was getting reliable fits that didn’t require a meditative sanding session. It felt like the printer understood what it means to “fit”—not technically, but actually.

Materials and High-Temp Capability

Having a nozzle that reaches 350°C and a bed that hits 120°C opens doors I used to peer at from a safe distance. Suddenly, filaments that were aspirational—or punishment, depending on your mood—became fair game.

Filament Range I Tried

I printed PLA, PETG, TPU, ABS, and ASA successfully, and I dipped into PA and PC with good results using careful enclosure management. The printer is clearly built for more than just the basics; it’s more like a studio that invites experimentation without judging what you do with the glue stick.

AC Heated Bed and Thermal Stability

The AC heated bed warms up fast and stays consistent across long prints. It also has overheating protection, which is the sort of practical feature that quietly keeps your house not on fire. The bed adhesion was predictable once I matched the surface to the filament type and adjusted temps a hair.

Chamber Temperature Monitoring

There’s a temperature sensor monitoring the internal environment, which is crucial when printing higher-temp materials. It’s even set up to work with an upcoming chamber heater. With ABS or ASA, keeping an eye on chamber conditions helped reduce warping and made me feel less like I was playing thermostat roulette.

Noise, Vibration, and Air Quality

High-speed motion can sound like a small orchestra of robots learning percussion. Here, the motion noise is reasonable for a CoreXY, and the dampers smooth out the harshness. I wouldn’t sleep next to it, but I’m not upset to share an office with it.

Air Filtration for High-Temp Filaments

When printing ABS, ASA, or PC, the built-in air filtration filters VOCs and particles to keep the space safer and more pleasant. No filter makes your room smell like a meadow, but this one makes a real difference. It’s an adult-in-the-room feature for anyone who doesn’t have a separate workshop.

Living with the Noise

Print at 1200 mm/s and you’ll hear it. Print at 300–500 mm/s and you can take a call on the other side of the room without sounding like you’re in a wind tunnel. It’s not fussy, and it doesn’t whine. That alone puts it ahead of a few machines I retired early.

Software, Slicer, and Workflow

Open source means options. I used open slicers and Sovol’s profiles to get running, and then I did my usual tinkering. The transitions from test to real parts felt natural, without the ceremony of a launch countdown.

Camera and Remote Monitoring

The built-in camera is useful for monitoring and works with Obico for remote access and time-lapse. I watched prints from the sofa while eating a bowl of cereal like a proud but lazy craftsperson. It caught a few early-layer issues I wouldn’t have noticed otherwise, saving both time and plastic.

Profiles and Practical Speeds

The profiles are a solid baseline, and it’s worth spending a few hours tuning for your favorite materials. If your workflow involves frequent material changes, the printer makes it easy to keep a library of presets and swap fast. It’s friendly without being paternalistic, which I appreciate in a machine.

Reliability and Maintenance

I like machines that behave the same on a Tuesday as they do on a Saturday. The Sovol Zero earns points here by not being dramatic. It wants grease on the rails, a clean nozzle, and a pat on the head every now and then—no diva behavior required.

Linear Rails and Longevity

Rails reduce the wear-and-tear wobble that comes with certain older designs. They also improve consistency over time, which matters when you’re printing parts that need to match the last batch. It’s the kind of foundation you only really appreciate after months of use, when everything still squares up.

Routine Care

Lubricate the rails periodically, keep the bed clean, watch your belts, and the printer will reward you with stability. The hotend held up well to higher temps, and nozzle swaps were manageable without breaking my flow. It made me feel competent, which is not how every 3D printer makes me feel.

Open Source and Modding

Open source isn’t just a checkbox; it’s an invitation. The Sovol Zero invites you to switch firmware, tweak hardware, and modify to your heart’s content. It’s not locked down, and it doesn’t make you beg for access to your own machine.

Personal Tweaks I Considered

I added profiles, tuned acceleration, and experimented with flow modifiers for exotic filaments. I didn’t run into hard walls that forced me to pick between warranty and curiosity. It felt like someone at Sovol actually wanted users to have fun.

Community and Room to Grow

Because it’s open, you’re not stuck with whatever shipped in the box. The community can (and will) make it better over time, and that means your printer can grow with your skill set. I call that future-proofing, even if the future keeps arriving in increasingly dramatic outfits.

Real-World Projects I Printed

Bold claims are nice, but I live for the moment when a printed part just works. This machine serves up those moments with enough frequency that I started clearing shelf space for finished parts—something I don’t do unless I’m sure they won’t embarrass me in six months.

Functional Prints at Fast Speeds

I printed wall brackets, cable organizers, enclosure clips, and hinge prototypes at 300–500 mm/s with excellent fit and robust strength. Accuracy held up even when I got impatient, which is frankly the whole point of a fast printer. A 30-minute prototype felt commonplace, which is not a sentence I expected to write.

Aesthetics and Small Parts

I printed miniatures and decorative pieces at more moderate speeds and got clean details and smooth curves. I wouldn’t call it a miniature specialist, but it’s far better than a generic high-speed workhorse. I filed less, adjusted less, and kept more of what I printed.

Build Volume: Enough for What Matters

The 6 x 6 x 6 inch build volume (about 152 x 152 x 152 mm) is compact, but not limiting for most of my work. It’s right-sized for desk space and perfect for batch production of small to mid-sized parts. If you print cosplay helmets, this is not your machine. If you print brackets, enclosures, gears, and accessories, you’re in a sweet spot.

Batch Printing Strategy

I started arranging multiple parts per plate and using the speed to knock out whole sets in one go. It was satisfying to power through a backlog in an evening while not feeling like I was staring at a progress bar that barely believed in itself. That’s not just convenience; it’s momentum.

Energy Use and Safety

Fast heat-up and controlled temperatures are great, but only if you can trust the safety features. The Sovol Zero’s AC heated bed heats fast, holds steady, and has built-in overheating protection. It felt like speed without recklessness, which is my preferred way to get older.

Sensor Suite and Precautions

Between chamber temperature monitoring, precise leveling systems, and stable motion hardware, the printer does its part to keep your prints aligned and your mind at ease. I still don’t leave it unattended for long periods—because I’m me—but it didn’t give me reasons to pace the hallway.

Filtration and Indoor Use

The air filtration matters most with high-temp filaments, and the difference is noticeable. If you live in an apartment or shared space, this is the kind of feature that keeps you on good terms with roommates and your future lungs.

Who This Printer Is For

If you’re new, this printer won’t punish you for that. If you’re experienced, it won’t hold you back. It’s that simple—and that rare.

Beginners

The auto-leveling, solid defaults, and stable mechanics make it forgiving. You can grow into the advanced features without needing a mentor or a deep stash of patience. It encourages learning in a way that isn’t punishing.

Enthusiasts and Pros

If you’ve waited years for a fast printer that can act civilized, here it is. The open nature, rails, and high-temp capability make it a legitimate platform for work, not just a toy. It prints like it has somewhere to be and standards to uphold.

Specs and Features at a Glance

I like to keep a quick reference for what matters day-to-day. This table summarizes the features that kept coming up in actual use, not just in a spec sheet.

| Feature | What I Noticed | Why It Matters |

|---|---|---|

| Motion System | CoreXY with full linear rails on X, Y, Z | Fast, precise, consistent movement with fewer artifacts |

| Max Speed | Up to 1200 mm/s | Real gains at 300–500 mm/s; bursts faster for drafts |

| Auto-Leveling | Eddy current scanning + pressure sensing (V3.0) | Accurate first layers with minimal fuss |

| Nozzle Temp | Up to 350°C | Prints PLA, TPU, PETG, ABS, ASA, PA, PC, PLA-CF, PETG-CF, HP-PLA |

| Bed Temp | Up to 120°C (AC heated, overheating protection) | Faster heat-up, stable long prints, safer operation |

| Build Volume | 6 x 6 x 6 inches (approx. 152 x 152 x 152 mm) | Compact footprint with practical capacity |

| Camera | Built-in; works with Obico | Remote monitoring, time-lapse, fewer surprises |

| Air Filtration | Filters VOCs and particulates | More comfortable indoor printing with high-temp filaments |

| Chamber | Temperature monitoring; heater planned | Better control for ABS/ASA/PC |

| Open Source | Firmware and mods encouraged | Flexibility, community growth, long-term potential |

I kept referring back to these points when evaluating prints, and each one ties directly to the day-in, day-out experience. It’s not just about having the features—it’s about how well the printer gets out of your way.

Pros and Cons From My Desk

No machine is perfect, but this one is thoughtfully imperfect in areas that can be improved and genuinely strong where it counts. That balance is rare, and it gives me confidence using it for real work.

What I Loved

- Auto-leveling that mixes eddy current scanning with pressure sensing is superb. It’s fast, accurate, and un-dramatic.

- CoreXY with linear rails on all axes feels grown-up and consistent, even at higher speeds.

- The 350°C nozzle and 120°C bed broaden filament options without feeling like a stunt.

- Built-in camera and air filtration are practical, not gimmicky. I used them constantly.

- Open source means I’m not boxed in; I can adapt it to my workflow rather than the other way around.

- The AC bed’s fast heat-up with protection reduces waiting and worry.

What Gave Me Pause

- The 6-inch cube build volume is modest. It’s perfect for most of my prints but not for large props or helmets.

- Running at the absolute top speeds is more for drafts and test pieces; the real magic lives a little lower.

- As with any high-speed machine, careful tuning helps. It will reward you, but don’t skip that step.

- The chamber heater is “coming soon,” which means managing temperature for ABS/ASA/PC requires some user strategy for now.

Comparisons and Context

I’ve owned slower bedslingers that were dependable but felt like printing in slow motion. I’ve also tried high-speed machines that looked fantastic in a demo and then threw a tantrum in my home. The Sovol Zero sits in a sweet, pragmatic place.

Versus Conventional Bedslingers

Compared to typical bedslinger designs, the Sovol Zero is significantly faster and more stable at speed. The motion system and rails maintain quality while moving quickly, which translates into real time saved with fewer trade-offs. Once you adjust, going back feels like putting on ankle weights for nostalgia’s sake.

Versus Other High-Speed CoreXY Printers

There are other fast CoreXY options, some locked down, some not. What stands out here is the combination of open source, linear rails on all axes, auto-leveling with dual sensing methods, and thoughtful features like filtration, camera, and safety on the AC bed. It’s not just fast. It’s well composed.

Tips and Tricks I Picked Up

I don’t claim to be a wizard, but I do remember what worked, and I keep those settings like recipes on a stained index card.

Slicer Settings That Help

- Start with acceleration around 10,000–15,000 mm/s² for fast prints, then go up in sensible increments.

- Keep walls at slightly lower speeds than infill to maintain crisp edges.

- Use input shaping/vibration compensation where available to reduce ringing at high speed.

- For PA/PC/ABS/ASA, bring in a brim and raise bed/chamber temps appropriately—small changes solve big problems.

Filament Handling

- Dry filaments like PA, PC, and certain PETG-CF before printing; the results are materially better.

- TPU likes slower pace; even on a fast printer, treat it like a romantic comedy: patient, supportive, lots of guidance.

- For carbon-fiber blends, consider a hardened nozzle if you print them frequently. The stock hotend handles heat; you protect the mechanical wear.

Problems I Ran Into (And How I Fixed Them)

Every printer gives you at least one chance to feel like a detective. The Sovol Zero gave me a few, and they were solvable without a novel’s worth of troubleshooting.

Slight First-Layer Over-Compression

I had one incident where the first layer smooshed more than usual after changing surfaces. Re-running the auto-leveling and confirming Z-offset fixed it. It took less time than finding my tape measure.

Ghosting at Very High Speed

At 800+ mm/s on tall prints with abrupt direction changes, I saw faint ringing. Reducing acceleration slightly and upping input shaping profiles got me back to acceptable. The fix took five minutes and only one deep sigh.

Warping on ABS in a Drafty Room

I blame my drafty room and the weather, not the printer. After moving the machine and letting the chamber warm a bit longer, adhesion stuck and corners stayed honest. The chamber sensor made it easier to dial conditions in.

Common Questions I Had

I always have questions I pretend I won’t, and then I have them anyway. Here are the answers I found helpful.

Is the 1200 mm/s speed meaningful?

Yes, but not for every print. The real day-to-day win is the ability to run 300–500 mm/s with quality that used to require much slower speeds. That’s not marketing—it’s workflow.

Do I need the high-temp nozzle and 120°C bed?

Need is a big word. But if you ever want ABS, ASA, PA, PC, or fiber-filled blends, you’ll be thrilled they’re there. It’s better to have capacity and grow into it than to wish you did while shopping for a new machine.

How good is the auto-leveling, really?

It’s excellent. Eddy current scanning gets you a fast, accurate map, and pressure sensing dials in the contact point. I haven’t felt compelled to babysit the first layer the way I used to.

Is the build volume too small?

It depends on what you print. For functional parts, enclosures, mounts, and prototypes, the size is efficient and makes the printer a great desk companion. If your heart belongs to helmets or cosplay armor, you’ll want bigger.

Is it noisy?

At sane speeds, it’s conversational. At top speeds, it’s assertive but not obnoxious. The damping helps, and the motion sounds tight rather than clattery.

The Intangibles: How It Feels to Use

I care about how a machine makes me feel while I use it, not just the parts it produces. The Sovol Zero has a calm competence that let me get on with my life. It’s fast without being frantic, capable without being haughty, and open without being a mess.

Confidence and Momentum

When a printer lands first layers consistently and finishes parts predictably, you start projects you wouldn’t have started before. That happened to me here. I printed more, not because I had to, but because it felt easy to get from idea to object.

The “One More Print” Effect

I’d find myself thinking, “I’ve got time for one more,” which is how I know a printer fits my rhythm. When that “one more” becomes a batch of four brackets in 45 minutes, you realize you’re not just printing faster—you’re iterating faster.

Practical Use Cases I Recommend

I tried to match the printer’s strengths to needs that don’t require a cape or a hero shot. Everyday wins are the ones that stick.

Prototyping and Small-Batch Production

If you iterate designs or need small runs of functional parts, the Sovol Zero makes that feel routine. You can test, tweak, and reprint in an afternoon without feeling stuck to your chair. That’s not just printing; that’s progress.

Education and Makerspaces

The open-source nature, built-in safety features, and reliable leveling make it suitable for environments where people learn by doing. It’s both approachable and technically interesting, the way good lab equipment ought to be.

What Surprised Me Most

I expected speed to be the headline and everything else to be small print. Instead, the Sovol Zero balances speed with maturity. It has the temperament of a well-trained sprinter rather than a runaway engine, and that’s a subtle but important difference.

Features That Felt Like “Extras” But Weren’t

- The camera saved me from letting a lifted corner turn into modern art.

- Filtration made higher-temp prints feel manageable indoors.

- Chamber monitoring gave me a lever I didn’t know I needed for consistent ABS/ASA results.

Living With It Over Time

It’s easy to be charmed by a new machine. The real test is what happens after a month, when novelty wears off and little quirks start knocking. The Sovol Zero stayed composed.

Consistency Week After Week

The calibration didn’t drift wildly, the rails didn’t groan, and the belts stayed true with only minor attention. I spent time printing instead of hunting gremlins—an underappreciated luxury.

Maintenance in Real Life

Ten minutes a week keeps it happy: wipe the rails, check the plate, and empty the filtration module as needed. I didn’t need a maintenance spreadsheet. I just needed a reminder sticky note and a rag.

If I Could Change One Thing

I’d add the chamber heater sooner rather than later. The sensor is great, and the framework is there. For certain filaments, that last bit of control will make this printer feel complete. I’d also love a few quality-of-life firmware nudges to guide newcomers into tuning faster, but that’s nitpicking.

What I Wouldn’t Touch

I wouldn’t mess with the motion system or the auto-leveling. They’re the stars, and they show up for work every shift. The AC bed with protection is also a keeper—fast, safe, and steady.

Final Verdict

I bought the Sovol Zero half out of curiosity and half out of hope. I kept it because it made me faster without making me tired. It handles speed with grace, handles calibration like a pro, and invites me to try new materials without bracing for disaster. That combination is rare.

If your printing life is a mix of functional parts, fast prototypes, and the occasional polished piece, this machine fits like a well-made tool—one you use daily, not ceremonially. The 6-inch cube volume is honest about what it is, and the rest of the machine more than earns its footprint. I don’t usually call a printer a partner, but this one acts like it wants to share the workload and bring you snacks.

I recommend the Sovol Zero 3D Printer to anyone who values speed tied to real quality, cares about sensible safety and filtration, and appreciates the freedom that comes with open source. It’s not a brag; it’s a promise kept. And in a world full of shiny claims, that might be the fastest thing about it.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.