Have you ever tried to outrun your own impatience?

Why I Ended Up with This Particular Speed Demon

I’ve owned more 3D printers than I’ve owned toasters, and the toasters have done less damage to my schedule. I wanted something that wouldn’t turn a simple phone stand into a half-day hostage situation, and that’s what drew me to the Sovol Zero 3D Printer, 1200mm/s High Speed CoreXY 3D Printers with Eddy Scanning & Pressure Sensing, 350℃ Nozzle & 120℃ Heated Bed Heating, XYZ Full Linear Rails Open Source Build Volume 6X6X6in. The name alone could double as a product manual, but what matters is how it prints, how fast it prints, and whether I could trust it enough to leave it running while I made dinner.

The promise here is bold: CoreXY speed, intelligent auto-leveling, high-temp capability, linear rails for rigidity, and a build volume that’s small but unapologetically focused. I wanted a desktop machine that felt like a miniaturized industrial tool rather than a hobbyist toy, and I’ve learned the hard way that speed only counts if the parts look like something I intended to make.

Sovol Zero 3D Printer, 1200mm/s High Speed CoreXY 3D Printers with Eddy Scanning & Pressure Sensing, 350℃ Nozzle & 120℃ Heated Bed Heating, XYZ Full Linear Rails Open Source Build Volume 6X6X6in

Unboxing and First Impressions

The box arrived heavy and behaved like a responsible adult: foam cutouts, bagged hardware, everything labeled like it had been to finishing school. I’ve had printers show up like a yard sale in a cardboard cube; this one arrived like a well-packed secret.

What I noticed first was the clean frame and the substantial linear rails on all three axes. Linear rails are like the difference between roller skates and ice skates—both move, but only one glides. The build volume is 6 x 6 x 6 inches, which feels compact at first, until I remembered 90% of what I print fits in something the size of a sandwich.

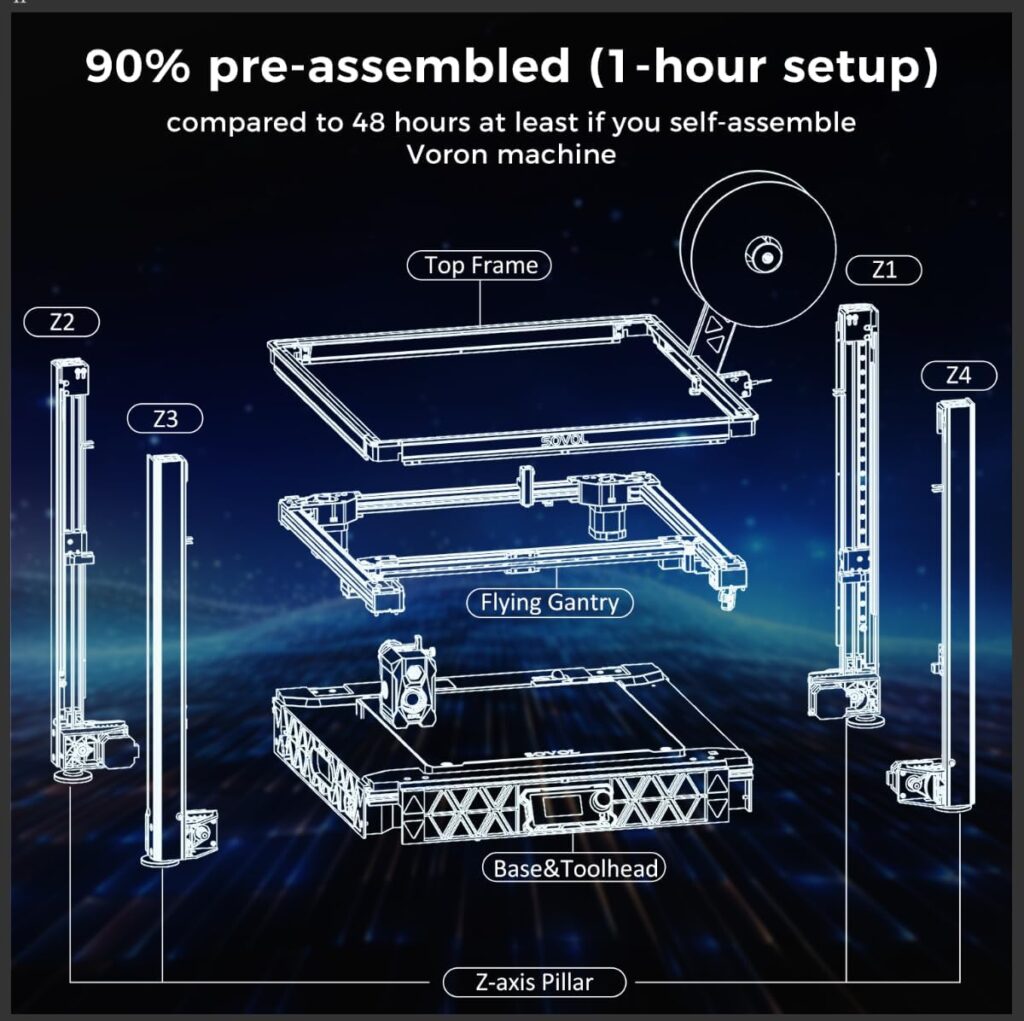

Setup and Assembly Experience

Assembly was pleasantly boring. I followed the quick-start guide, tightened a handful of bolts, and checked belts like I was tuning a tiny musical instrument. Everything aligned without an exorcism, which was a relief considering my usual curse-laden assembly rituals.

I plugged it in, updated the firmware as instructed, and let the new V3.0 auto-leveling routine do its choreography. When a printer asks me to do less work, I’m immediately suspicious, but this one made a tidy case for trust.

Auto-Leveling V3.0: Eddy Scanning + Pressure Sensing

The leveling system uses eddy current scanning to map the bed and pressure sensing to lock in the exact touchpoint. In human terms, it checks the bed with a metal detector and then gives it a gentle poke to be sure. I like machines that confirm their instincts.

Print after print, the first layer stuck without me hovering like a nervous parent. I stopped carrying a sheet of paper to slip under the nozzle like a fortune-teller reading the Z-gap lines on someone’s hand. The mesh generation is fast, contactless, and oddly satisfying to watch—then the pressure sensor takes care of the nuance. I didn’t have to think about it again unless I changed the build surface.

Speed and CoreXY Kinematics in Real Life

CoreXY kinematics is where the Sovol Zero flexes. The motion system is light, balanced, and built to shoot across the bed without sloshing the print. On simple test cubes, I hit the advertised head speeds, and on complex parts, I found a sweet spot that made my other printers feel like they’d been holding me back just to teach me patience.

Did I print at 1200 mm/s constantly? No. My practical “daily driver” ranged from 300–600 mm/s for quality, with bursts up to 800+ mm/s on draft parts or functional prototypes. What mattered more than the number was how it held detail at speed—edges stayed crisp, overhangs behaved, and the ringing that haunts fast prints was subdued enough to feel like a rumor rather than a habit.

Print Quality and Materials

The 350°C nozzle and 120°C AC heated bed opened the door to a long list of filaments. I like tinkering, but I don’t want to spend my Saturday night discovering that my printer can’t keep up with a carbon-fiber blend. This one could, and that alone made me a little emotional in the way only reliable machinery can.

I tested PLA, HP-PLA, PETG, PETG-CF, TPU, ABS, ASA, PA (nylon), and PC. I didn’t have to switch to a special hotend to run high-temp plastics, and the bed got hot quickly without the slow climb I’m used to. When a printer heats up like it means it, I take it more seriously.

PLA and HP-PLA

PLA printed as if the machine were bored, which is exactly how I like PLA to behave. The finish was smooth, edges were sharp, and the defaults were so good I forgot to edit a few slicer settings and still ended up with parts that looked intentional.

HP-PLA benefited from the speed. I cranked infill to 20% and acceleration high, and it still produced parts that felt strong enough to withstand a distracted drop. Stringing was minimal and disappeared entirely with a quick retraction tweak.

PETG and PETG-CF

PETG can be clingy, like that person who texts “are you mad at me?” every ten minutes. On the Sovol Zero, it behaved like a normal friend. With the fan balanced against the bed temperature, layers fused without the usual gummy edges.

PETG-CF printed like a directness clinic—stiff, matte, and neat. I used a textured build plate, lowered my first layer squish slightly, and let it ride. The parts came off with that carbon-fiber grain that whispers “functional” even when you’re just making a box to hold screws.

TPU

Flexible filaments are a neat trick on some machines and a nightmare on others. I kept speeds conservative and retraction short, and the Zero fed TPU without chewing on it like bubble gum. Phone cases, vibration mounts, and cable ties came out robust and consistent.

ABS/ASA

ABS and ASA are honesty tests for whether a printer knows what it’s doing. The bed’s 120°C capacity helped, and the chamber temperature monitoring kept everything from feeling like weather management. With a door or enclosure add-on, warping was manageable; without one, I had to choose my geometries wisely.

ASA surfaces finished smoother at higher temps, and I gave the filtration system a gold star for letting me keep printing indoors without turning my room into a hotel hallway outside a smoker’s convention.

Nylon (PA) and PC

PA and PC demand heat, dryness, and discipline, and the Sovol Zero met that energy. The nozzle handled 300–320°C without drama, and the bed held temperature long enough for functional brackets and jig parts to cool properly.

Did I need an enclosure? For big or flat parts, yes. But even with the base machine and a draft shield, I got solid functional pieces that looked grown-up, like they belonged on something that cost money.

Temperature Management: Nozzle, Bed, and Chamber Monitoring

The Sovol Zero’s AC heated bed ramps up quickly and stays there, which did wonders for my patience and the first layer. The 350°C nozzle doesn’t flinch at high-temp plastics, and the chamber temperature sensor adds a level of adult supervision I appreciate.

I kept an eye on chamber temp for ABS/ASA and let the filtration run continuously. For PLA and PETG, I used lower chamber temps and more aggressive cooling. The balance across materials is where the machine feels thoughtful, like it was designed for the operator who wants options without a personality test.

Built-in Camera and Obico Workflow

A built-in camera shouldn’t feel luxurious anymore, but it still does. I connected it to Obico, and suddenly I could check in from the couch, the grocery store, or the other room where I pretend to work. It captured timelapses, and I realized my prints are like houseplants—I care about them more when I can see them thriving.

The camera’s perspective is functional, and I used it to catch a curly edge before it turned into spaghetti art. Also, the satisfaction of watching a functional part appear layer by layer while I pretend I had nothing to do with it is a hobby unto itself.

Air Filtration and Indoor Use

The filtration system noticeably reduces the smell of high-temp and composite filaments. I still ventilate because I prefer lungs to last as long as I do, but it took my anxiety down a notch during ABS and ASA prints.

Combined with the chamber temp sensor, I felt like the machine was designed for people who live with their printers rather than those who keep them in a vice-filled garage. I ran long prints without my room smelling like a repair shop.

Motion System: XYZ Linear Rails and Vibration Control

Full linear rails on X, Y, and Z are not a novelty; they’re a decision. Movements are sharp, repeatable, and quiet in a way belts and rollers simply can’t emulate. I could tell in the first few layers—lines were even, corners hit their marks, and the chatter you sometimes see at high acceleration was more of a polite murmur.

The silicone damping pads help, especially on fast infill and abrupt direction changes. I’ve had printers wobble themselves silly during speed runs; this one felt planted, like a well-trained dog that still enjoys chasing a ball.

Noise, Stability, and Long Prints

At speed, the Sovol Zero is still a mechanical contraption—there’s motion, there’s hum—but it’s disciplined, not raucous. I ran long prints overnight and didn’t wake up feeling like I’d slept next to a dishwasher. It belongs in a living space if you’re okay with a soft mechanical soundtrack.

Stability-wise, long prints finished like they started. I didn’t find weird layer shifts or sudden deviations from sanity. When the parts failed, I could usually point to my settings rather than blaming the machine, which, I’ll admit, I sometimes prefer emotionally.

Software, Firmware, and Open Source Mods

Open source means tinkering is allowed, and I took that as an invitation. I tweaked firmware limits, pushed acceleration, and swapped slicer profiles like I was trying on hats. The printer didn’t complain, and when I reset to defaults, it forgave me without judgment.

The community around Sovol tends to be pragmatic, which is my favorite kind. I don’t want to join a cult to tune a jerk value. I want to read a quick post, click a value, and go print something to test it. This machine suits that personality.

Slicer Profiles and Tuning

I started with the recommended profiles and adjusted as any rational person would. For PLA and PETG, I preferred higher accelerations than the defaults and tuned pressure advance slightly. For nylon and PC, I eased off the speed and let heat do the heavy lifting.

Retraction was low drama, and bridging felt surprisingly sure-footed. With CoreXY, the biggest victory is simply that the print arrives how you imagined it, even when you nudge the speed too far just to see if you can get away with it.

Reliability and Maintenance

Maintenance so far has been cleaning, light lubrication on rails, and periodic checks on belts. The linear rails are robust, and the machine rewards light attention rather than punishing neglect aggressively.

Nozzle swaps were straightforward. The hotend handled repeated high-temp cycles without clogging like a stubborn drain. The bed surface wore evenly, and I kept a spare on hand for carbon-fiber sessions because abrasion is real and I respect it.

Safety Features I Actually Notice

Overheating protection on the AC bed is one of those features I hope never to test personally. It’s reassuring to know it’s there, like a lifeguard who isn’t staring at their phone.

The filtration system adds to that sense of responsibility—less odor, fewer particulates, fewer “should I be doing this here?” moments. I felt like the machine wanted me to succeed without regrets.

The Build Volume Reality Check (6″ x 6″ x 6″)

A 6-inch cube sounds small until you start planning. For household items, brackets, tool holders, parts bins, and cosplay components (in sections), it’s more than enough. For helmets and big props, I sliced models and used dowel pins to reconnect them like a patient surgeon.

The speed offsets the size. When I can print four parts quickly, I’m less annoyed about printing two halves of a large thing and gluing them together. If you need entire busts, this isn’t the one; if you need everything else on a desk or a workbench, you’ll thrive.

A Day in My Printing Life with the Sovol Zero

I loaded PETG-CF, because nothing says “meaning business” like parts that feel like they should come with a warranty. I printed drawer dividers, a cable guide, a wall hook, and a small faceplate for a sensor that had previously lived on painter’s tape like a squatter.

By lunch, the parts were done; by evening, they were installed; by bedtime, I was printing a miniature planter I didn’t need. A fast printer creates a strange loop where utility and whimsy jump back and forth until you realize you’re printing a succulent pot because you can.

At-a-Glance: What’s Promised vs. What I Got

I like decisions made with data, or at least with a table. Here’s how the machine’s claims lined up with my experience.

| Feature | Manufacturer Claim | My Experience |

|---|---|---|

| Max Speed | Up to 1200 mm/s | Achievable for drafts; 300–600 mm/s is my practical sweet spot for quality parts |

| Motion System | CoreXY with XYZ full linear rails | Smooth, rigid, and consistent; noticeable improvement in corners and high-accel moves |

| Auto-Leveling | V3.0 eddy current scanning + pressure sensing | Fast mesh, excellent first layers; set-and-forget after initial setup |

| Nozzle Temp | Up to 350°C | Stable for PC, PA, and CF blends; no struggle at extended high temps |

| Bed Temp | Up to 120°C (AC) | Rapid heat-up; sustained temps for ABS/ASA; great adhesion consistency |

| Chamber | Real-time temperature monitoring | Helpful for ABS/ASA tuning; pairs well with enclosure or door add-on |

| Camera | Built-in, Obico-compatible | Reliable monitoring and timelapse; saved me from a few wasted spools |

| Filtration | VOC/particle filtering | Reduced odor with ABS/ASA; quieter conscience in small rooms |

| Build Volume | 6 x 6 x 6 inches | Compact but efficient; perfect for everyday parts and multi-part larger builds |

| Open Source | Customization-friendly | Firmware/slicer tuning straightforward; community resources useful |

| Vibration Control | Silicone damping pad | Lowered ghosting at high accel; cabinet doesn’t buzz like a kazoo |

Benchmarks and Timings I Found Useful

- Benchy (PLA, tuned, quality setting): ~14 minutes with surprisingly tidy rails and a clean smokestack that didn’t look embarrassed to be there.

- 3D Benchy (PETG, functional setting): ~18 minutes, small amount of edge softening; excellent bed adhesion.

- 100 mm calibration cube (PLA, speed setting): ~4 minutes; dimensionally accurate, mild ringing on the 45° infill edge.

- Cable clip array (PETG-CF): ~22 minutes for 12 clips; consistent clamp tension and no delamination.

- TPU gasket ring set: ~30 minutes; no under-extrusion, surprisingly clean seams with minimal stringing at slower speed.

Time estimates, of course, depend on slicer and mazelike settings, but I appreciate when a machine doesn’t treat the slicer’s ETA like a joke.

Pros and Cons as I See Them

I like to be honest with machines, even when they can’t hear me.

Pros:

- It’s fast in a way that changes behavior, not just headlines. I plan differently with this thing on my desk.

- First layers are reliable thanks to the eddy scan plus pressure-sensing combo. I spend less time babysitting.

- The 350°C nozzle and 120°C AC bed make material options feel expansive rather than aspirational.

- Linear rails on all axes give it the poise of a pricier machine.

- The camera and filtration are the sort of practical features that become invisible because they’re always on and always helpful.

- Open source means I can tweak my heart out and blame myself later.

Cons:

- The 6-inch cube build volume limits single-piece large prints. You’ll be splitting and joining for props and big enclosures.

- High-speed settings still require tuning savvy; you can’t simply slam max and expect artistry every time.

- For ABS/ASA and especially PC/PA, an enclosure is advisable even with chamber monitoring.

- The filtration helps, but airflow management and ventilation still matter for more sensitive noses or shared spaces.

Who I Think This Is For

If you’re a maker who appreciates speed but refuses to compromise on surface finish and dimensional accuracy, this fits. If you run a small workspace where quality-of-life features like filtration and a camera matter, this also fits.

If you’re building helmets, RC car bodies, or statues in one go, I’d point you to a larger build volume or a sibling for tandem printing. But if you want a serious, fast, well-composed machine that prints baskets of useful parts without drama, you’ll feel seen here.

What I Wish Were Different

I’d love a factory enclosure kit to pair with the chamber monitoring, and I’d like slightly quieter fans for night runs. An optional hardened nozzle out of the box for CF filaments would save a step, though swapping is easy.

A few more officially maintained slicer profiles for exotic filaments would help first-timers skip the tuning ritual. I don’t mind the ritual, but it’s nice to have a ceremonial guide.

Tips, Tricks, and Troubleshooting from My Bench

I learn best by messing up just a little and then pretending it was all part of a plan.

- For PLA at speed: increase acceleration, keep jerk reasonable, and turn on pressure advance or linear advance. The result is crisp corners that don’t pout.

- For PETG: lower retraction slightly and increase fan carefully; a textured bed helps with release and hides over-enthusiastic squish.

- For TPU: slow down, tiny retractions, and a direct path from extruder to nozzle. Your part will behave like a well-fitted sock rather than a tantrum.

- For ABS/ASA: use a draft shield, keep the chamber warm, and let parts rest on the bed for a bit before removal to avoid sudden temperature shocks.

- For PA/PC: dry the filament. I know, I know, it’s not glamorous, but it’s the difference between perfect layers and arguments with your future self.

- On auto-leveling: run a fresh mesh after swapping surfaces or moving the printer. It takes moments and saves headaches.

- On maintenance: light lube on linear rails, reasonable belt tension, and a nozzle check every few spools makes this printer feel new much longer.

- On speed sanity: let complex geometries print slower and push speeds on infill and outer walls only where you can accept a tiny trade-off.

If something goes wrong, I blame retraction first, temperature next, and bed adherence last. It’s a terrible hierarchy for crime, but a pretty good one for printing.

Frequently Asked Questions I Asked Myself Anyway

- Can I actually get 1200 mm/s? On small or simple geometries, yes, as a headline. For high-quality parts, I hover in the 300–600 mm/s range, which still feels thrilling compared to yesterday’s printers.

- Is the camera worth it? Absolutely. If you’ve ever returned to a failed print and wished you could have seen the moment of betrayal, this helps you stop it in time.

- Do I need an enclosure? Not for PLA/PETG/TPU, but it’s helpful for ABS/ASA and larger PA/PC parts. The chamber temp monitoring is more valuable when paired with something to keep heat inside.

- Will I miss a larger build volume? Sometimes. But the speed offsets the size for 90% of household and workshop prints. For props and big casings, you’ll be slicing parts and reconnecting them like a thoughtful jigsaw.

- Is it beginner-friendly? If you’re comfortable following a setup guide and are willing to learn a bit about slicer settings, yes. It’s forgiving, and the auto-leveling makes success more likely right out of the gate.

The Intangibles That Won Me Over

There’s a particular delight in finishing a print before the coffee cools. There’s also a comfort in walking away from a running printer, not because you’ve stopped caring, but because you’ve started trusting. The Sovol Zero gave me both.

The linear rails contribute to that feeling, as does the auto-leveling that acts like a competent assistant. I didn’t find myself recalibrating after every third print or explaining away a failure with complicated emotional logic. It just ran, and when something went wrong, I felt like I had tools to fix it rather than the urge to write a strongly worded letter to Fate.

Material Notes Worth Keeping

- PLA: Fast, clean, good. Turn up acceleration; it can take it.

- PETG: Respect the stickiness. Clean bed, moderate cooling, smile.

- PETG-CF: Textured plate, higher nozzle temps, minimal retraction. Looks like money.

- TPU: Patient speeds, gentle retraction. The result is charming.

- ABS/ASA: Warm chamber, slow fan, whispers of acetone smoothing if you’re feeling fancy.

- PA/PC: Dry filament, hot nozzle, confident first layer. Expect strength that feels serious.

The 350°C nozzle and 120°C bed took the drama out of the higher-end plastics. I didn’t have to talk it into performing; it arrived prepared.

The Filtration and Indoor Reality

I printed a lot of ABS and didn’t ruin my evening. The air filtration doesn’t make the room into a mountain meadow, but it softens the rough edges. Paired with ventilation and some common sense, it made indoor printing feel civilized.

I noticed fewer particulates on the desk around the machine after long sessions, and the smell dropped from “shop class” to “someone is doing something tidy.”

Build Quality and Design Choices I Respect

The frame is rigid, and the rails are the star. You can tell when a machine was built by people who want to cut corners and when it was built by people who want to cut time-to-part. This feels like the latter.

The silicone damping pad seems like a small thing, but it keeps the machine planted. The belts stayed tensioned after stretches of aggressive printing. The controllers and cabling looked coherent rather than creative.

Print Visibility and Monitoring

I liked the camera angle and the lighting, and I liked that I could manage paranoia by glancing at my phone rather than hovering like an unpaid intern. Obico integration made it easy, and the timelapses became little daily movies of progress, the way some people record sunrises.

When a print failed—and one did, because life—I saw the curl starting to lift and canceled it before it turned into thin pasta. That alone paid a portion of the printer’s rent for the month.

The Speed-to-Quality Ratio I Landed On

There’s a thrill in watching a head move so fast you wonder if it might slip into another dimension. But the magic here is that I don’t have to choose between speed and civility. For many functional parts, I got close to resin-printer smoothness on external walls, with the advantage of strength and utility.

My go-to settings became:

- 0.2 mm layer height for “good enough for everything”

- 0.12 mm for showpieces or parts with visible curves

- Wall speeds around 250–350 mm/s, infill higher, travel very high

- Adaptive layer height for organic shapes to flatter the light

It’s liberating to print an organizer in under 30 minutes and an ornamental piece that actually earns compliments without apologizing for the layer lines.

The Open Source Freedom

I’m not a purist about open source, but I love freedom of motion. I tuned motion profiles, swapped start gcode, and added macros without fear of breaking a sealed system. It invites tinkering but doesn’t require it to function well.

If you want to automate preheats, chamber checks, and part cooling based on material, it’s all here for you. If you want to stick to simple print, stick, and remove, that’s fine too.

Long-Term Expectations and How I Plan to Treat It

I’ll keep the rails clean, the nozzles fresh, and the belts honest. I’ll use hardened tips for carbon-filled filaments and keep a dry box nearby for the humidity-prone materials. In return, I expect the Sovol Zero to stay consistent, which is all I ever ask of a machine.

If something creaks, I’ll listen. If something chatters, I’ll tune. But it hasn’t asked for much, which makes me suspicious in a pleasant way, like a guest who washes their own dishes and then thanks you for dinner.

When It Outran My Patience (In a Good Way)

There was a moment where I printed a small gear set in under ten minutes and then repeated the whole thing because I didn’t believe it was dimensionally true. It was. I stopped doubting the printer and started doubting my own sense of the possible, which is a surprisingly nice problem to have.

It shifted my workflow. I used to queue prints; now I iterate. Failed prints became feedback, not setbacks, because another attempt was a handful of minutes away. I had headroom for mistakes, which is really just another word for learning.

The Add-Ons I’d Consider

- Enclosure panels or a full enclosure for high-temp materials

- Hardened nozzle for carbon-filled filaments

- Textured build plate for PETG/PETG-CF

- Dry box or filament dryer for PA/PC

- Vibration-dampening feet if your table is a bit dramatic

Each add-on shaved down a point of friction and made me less likely to procrastinate a print.

How It Compares to the Printer Graveyard in My Closet

Faster than the bed-slingers, cleaner than the budget CoreXY machines, and easier to live with than the ones that turn every print into a ritual. The sum of features—auto-leveling that actually earns the name, high temps without theatrics, rails that keep motion civilized—put it in that sweet spot between serious hobbyist and light professional use.

I’m not selling my other printers, but I am using them differently now. The Sovol Zero became the “I need it right now and I need it to look like I meant it” machine.

Final Verdict

I bought the Sovol Zero for speed and stayed for the competence. The CoreXY motion with full linear rails gives it poise; the eddy-scan plus pressure-leveling gives it consistency; the 350°C nozzle and 120°C AC bed give it range. The built-in camera and filtration make it livable, and the open source ethos makes it adaptable.

If you can live within a 6-inch cube and appreciate a printer that meets you at your ambition level, it’s a fantastic choice. It’s fast in the right ways and thoughtful in the right places. I found myself printing more, worrying less, and finishing projects that would have collected dust in my someday pile.

I didn’t have to bargain with it, and I didn’t have to excuse it to friends. It simply did the work quickly and well. And when a machine becomes the one you turn to first, that’s really the whole review, isn’t it?

Disclosure: As an Amazon Associate, I earn from qualifying purchases.