Would you mind if I use a humorous, self-deprecating, observational tone rather than an exact imitation of any specific writer while I tell you what it’s like to live with the Creality Ender 5 Max 3D Printer?

Why I Bought a Giant, Fast 3D Printer

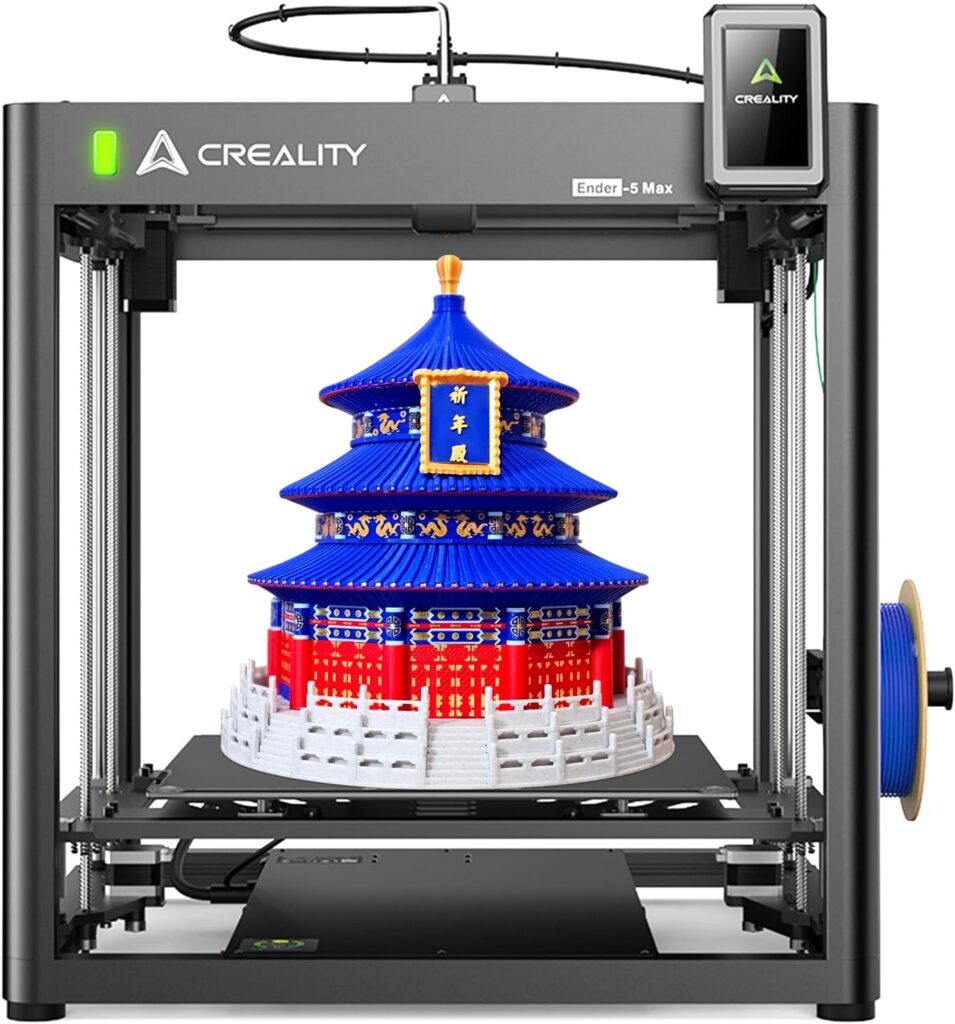

I had a moment where I realized my projects were bigger than my printers and my patience was shorter than my print times. I wanted a machine that would sprint instead of stroll and build big without flinching. The Creality Ender 5 Max promised both: a 400 × 400 × 400 mm build volume and a blistering top speed of 700 mm/s, with a 64-point auto-leveling system to keep everything tidy. I told myself this wasn’t indulgence; this was efficiency.

And if I’m honest, I’ve always had a soft spot for big, boxy printers that look like they mean business. The Ender 5 Max, with its cubic frame and serious linear rails, gave me the kind of confidence I usually reserve for power tools, airline pilots, and people who fold fitted sheets correctly on the first try.

Creality Ender 5 Max 3D Printer, 3D Printing Machine with 700mm/s High-Speed Printing, 400 * 400 * 400 Large Print Area, 64-Point Auto Leveling 300℃ High Temp Precise Linear Rail

$749.00 In Stock

The Headline Features That Matter in Real Life

When I read the spec sheet for the Ender 5 Max, I felt like I was being seduced by numbers. But numbers don’t always translate to real prints. Fortunately, here, many of them do.

- 700 mm/s printing: That’s the headliner. In practice, I got mind-blowingly fast perimeter speeds on simple geometries and very respectable speeds on complex parts, with sensible slicer tuning.

- 400 × 400 × 400 mm build volume: I stopped slicing large objects into compromises and instead printed what I actually wanted.

- 64-point auto leveling: My first layers stopped being a negotiation and became a routine convenience.

- 1000W heatbed: I wasn’t left waiting to warm up; I was left scrambling to find my scraper because the print had already started.

- 3-color status indicator: From across the room, I could tell if I should go make tea or come running.

None of that matters if the printer can’t keep its bearings, so the inclusion of precise linear rails and beefy 42-76 stepper motors for the X and Y axes gave me the mechanical backbone I wanted.

Setup: My Experience Getting It Ready

I’m not a masochist, but I do like assembly. It gives me time to bond with the machine and hear my inner monologue say, “Are you sure that’s square?” With the Ender 5 Max, the process was straightforward and orderly. The frame pieces are substantial, and once tightened correctly, they form a rigid cube that fundamentally supports the speed claims.

I squared the frame carefully and double-checked the belts for equal tension. If you skip that part, you’ll spend the next few days wondering why your circles look like melancholy ovals. The cable routing was sensible, and the connectors were labeled clearly enough that even I—who has once wired a fan backwards on a Sunday morning—got it right the first time.

By the time I powered on, I felt like I knew where everything was. And of course, the first function I went for was the 64-point auto leveling. I watched the nozzle do its little tap dance across the bed, charting its mesh like a cartographer who’s paid by the data point.

First Prints: What I Saw Right Away

My first calibration prints told me the story I’d hoped to hear: the first layer adhesion was consistent, the lines sat down like obedient ribbons, and corners were crisp, even at more aggressive speeds than I’d usually try on a fresh machine. I nudged the speed and acceleration settings up cautiously, like testing the limits of new sneakers on a slick floor.

Did I immediately print at 700 mm/s? No. I’m ambitious, not reckless. But I did ramp up to the kind of speeds that would make my older machines raise an eyebrow and maybe throw a belt. The Ender 5 Max handled it with the calm of a librarian who’s seen everything and cataloged most of it.

The Speed Question: 700 mm/s and the Truth I Found

Speed in 3D printing isn’t just about how fast the nozzle can drag around molten plastic. It’s about acceleration, jerk, the rigidity of the frame, and whether the part you’re printing is a delicate lattice or basically a box pretending to be a vase.

Here’s my reality:

- On simple shapes and draft-quality prints, I reached very high speeds without the artifacts that usually scream “slow down.”

- On complex functional parts, I settled into a sweet spot that felt sustainable: fast enough to impress, slow enough to keep quality consistent.

- The 42-76 stepper motors on X and Y matter. They help keep motion firm and predictable when inertia wants to write its own story.

Could I hit 700 mm/s? Yes, in controlled tests and on specific geometries. Could I print everything that way? Of course not. But that top end widened what I could attempt. It gave me headroom—like owning a car that can go far beyond the speed limit, even though most of the time I’m just trying to merge without humiliation.

Big Build Volume: How I Used All That Space

The 400 × 400 × 400 mm space changed my approach. I printed single-piece cosplay helmets that didn’t require a surgical degree to assemble. I printed tool organizers that encompassed the entire tool set, not just the idealized version I wish I had. I printed tall, elegant vases (spiral mode, obviously) that didn’t have to be compressed like a suitcase before a weekend flight.

Even if I wasn’t building giant pieces, I could batch print. A dozen brackets at once? Fine. A farm of little widgets for friends who think I run a personalization kiosk? Also fine. The bed is large enough that I started breaking my own habit of trying to cram everything into the front left corner. The rest of the bed isn’t decorative—it’s usefully flat and consistent, thanks to that 64-point mesh.

That 64-Point Auto Leveling: First Layer Security

I used to think manual bed leveling was a character-building exercise, but only if the character is a grumpy person with achy fingers. With 64-point auto leveling, I stopped doing improvised squint-based calibration. The mesh compensates for micro-variations in the bed surface, and the nozzle simply behaves.

What I noticed:

- My first layers became predictable. Predictability, in 3D printing, is more precious than speed.

- I spent less time reprinting the first 3 mm of a part and more time printing the remaining 397 mm.

- Once in a while, I still check gantry squareness and belt tension, because no mesh in the world can fix a loose belt. But now those checks feel like proactive maintenance rather than constant troubleshooting.

The Heatbed: 1000W and No Waiting Around

If you’re used to beds that creep toward temperature like a sleepy cat on a cold morning, the 1000W heater is a rude awakening—in a good way. Getting to 80 °C in about 200 seconds meant I stopped pacing around the room pretending to “tidy” while I waited. Maximum 100 °C covers PLA, PETG, ABS, ASA, and many PA mixes, provided you’re smart about your environment.

What that means for me:

- Less time warming up, more time printing.

- ABS and ASA became feasible on a larger surface, though I do recommend some kind of enclosure for those materials to prevent warping. The printer is open-frame, so I improvised a removable enclosure when necessary.

- Bed adhesion improved, especially with the right surface prep. A little glue stick or a PEI sheet can turn a normal print into a predictable one.

High Temperature Printing Up to 300 °C

A 300 °C nozzle expands my filament palette comfortably. I printed PLA and PETG like always, but I also ventured into ABS, ASA, and nylon (PA). Each has quirks, and none likes a drafty room. With the Ender 5 Max, high-temp printing felt less like extracurricular bravado and more like a real option.

My tips:

- For nylon or ABS/ASA, use an enclosure, keep the area calm, and pre-dry the filament. Nylon is hydrophilic and will punish you for ignoring it.

- Use a suitable bed surface and adhesion aid for the material. Nylon likes a textured surface or specialized adhesion sheet. ABS sticks better with glue stick or ABS slurry.

- High temps are an invitation to print functional parts. I printed gears, brackets, and hinges that didn’t flinch under use.

Linear Rails and Motion: Why the Prints Look Clean

The “precise linear rail” on the motion system is not just a bullet-point brag. It’s part of why corners are consistent and why ringing is minimized when you push speeds beyond the comfort zone of most bed slingers. The frame’s cubic geometry helps too—motion is contained and not fighting gravity in quite the same way.

As I nudged acceleration upward, I watched for telltale ripples and found far fewer than I expected. When I did see artifacts, they were manageable with slicer tuning and reasonable speeds. I never felt like I hit an invisible wall. That’s rare.

The Three-Color Status Light: A Surprisingly Helpful Habit

I didn’t think I’d love a 3-color indicator light. Then I started watching it from across the room like it was a status signal from mission control. It’s visible up to 10 meters, which is perfect if you have other printers, a cluttered workshop, or an attention span that occasionally wanders.

- Green: the print is healthy and humming along.

- Another color for certain states, another for alerts. I learned to glance and decide whether to carry on or investigate.

- I no longer stood over the printer like a nervous parent. I could sit back down, pretend to answer emails, and only intervene when the light suggested I should.

Slicing Settings That Worked for Me

Every printer has a temperament. The Ender 5 Max likes a few things in particular:

- Layer height: 0.2 mm for general use, 0.12–0.16 mm for detail, 0.28 mm for draft.

- Speeds: 200–300 mm/s for perimeters on many parts, higher for infill and travel on simple shapes.

- Acceleration: I varied it depending on part complexity, balancing speed against ringing. I kept external perimeters slower and gave infill the freedom to fly.

- Cooling: PLA appreciates robust cooling; ABS/ASA do not. I treated cooling as a material-specific setting, not a printer preset.

- Flow calibration: I always run a flow test and tune extrusion multiplier. Big machines make little mistakes obvious.

I printed successfully using common slicers and stuck to sensible profiles as a base. I then tuned speeds upward, testing first on geometry that was tolerant of missteps. There’s no medal for reckless bravery in this hobby, only spaghetti.

Print Quality: What My Parts Looked Like

After the calibrations and tests, my functional parts came out with:

- Strong layer adhesion when I used suitable temperatures and slowed down where strength mattered.

- Clean perimeters with minimal ringing for the speeds involved.

- Excellent first layers, which made everything on top look better automatically.

- Corners that behaved. Not every printer respects a corner. This one mostly does, provided I don’t bully it.

Surface finish will always reflect speed choices. When I wanted perfection, I slowed down. When I wanted “very good at record time,” I sped up. Having the option was the win.

Noise, Vibration, and Living With It

At speed, the machine has a confident hum and the fans remind you they’re helping. The frame doesn’t rattle, and stepper chatter is present but not obnoxious. I wouldn’t put it in a nursery, but in a workshop or office, it’s civilized enough that I can hold a conversation or think my thoughts without resenting it.

Vibration control is helped by the sturdy frame and linear rails. I put it on a solid table and it rewarded me with stable prints and fewer little wobbles that make your parts look like they’re holding their breath.

Maintenance: What I Actually Had to Do

Reliable machines are not no-maintenance machines. I treat 3D printers like bicycles: a little attention prevents drama.

- Belts: I checked tension every couple of weeks until I trusted they’d settled.

- Rails: I kept them clean and lightly lubricated as recommended for linear rails.

- Nozzle: Hotend at 300 °C means you need to manage filament types and keep the nozzle clean. I used a brass brush and cold pulls when necessary.

- Bed surface: Kept it clean, light alcohol wipe, careful with adhesives so I didn’t bake glue into folklore.

The good news: nothing felt fussy. It felt like routine care instead of constant triage.

Power and Safety: Thoughts on the 1000W Bed

A 1000W bed is a commitment. My circuit handled it just fine, and warmups were quick. I don’t run the printer during lightning storms or while I leave the house for the weekend, because I practice what I call “sensible paranoia.” For long prints, I used a smoke detector in the room, surge protection, and common-sense cable management. If that sounds excessive, good. Excessive caution is underrated.

Materials I Printed and What Happened

- PLA: Predictable, glossy, fast. Loves cooling, hates heat creep—though the hotend managed long prints beautifully.

- PETG: Slightly slower, stronger, benefits from reducing fan speed to avoid brittleness. Adhesion was solid on a textured surface.

- ABS/ASA: Benefits immensely from an enclosure. Layer splitting minimized when I kept the environment warm and consistent.

- Nylon (PA): Consistent results after drying. Strong, springy parts that made me feel like an engineer even when I was just printing a clip for a broom.

I printed composites judiciously and changed nozzles when abrasives were involved. Not every print needs to be exotic. Sometimes PLA is the correct answer, especially when you’re validating a design.

The Table I Wish I’d Seen Before Buying

| Feature | What It Means in Use | My Experience | Notes |

|---|---|---|---|

| 700 mm/s top speed | Extremely fast motion capability | Excellent for simple shapes; high-speed infill; sensible speeds for complex parts | Quality vs. speed is a dial, not a switch |

| 400 × 400 × 400 mm build volume | Print big models or batch small ones | Printed helmets, organizers, tall vases, multi-part batches | Bed is consistently usable across the surface |

| 64-point auto leveling | Smooth first layers with mesh compensation | First layer issues dropped dramatically | Still square the frame and set belt tension |

| Precise linear rail | Rigid, smooth motion | Less ringing; better corner fidelity at speed | Keep rails clean and lubricated |

| 3-color status indicator | At-a-glance printer status | I glanced from across the room and knew what to do | Helpful in multi-printer setups |

| 1000W heatbed | Fast heat-up; large thermal mass | 80 °C in ~200 seconds; less waiting | Consider enclosure for high-temp filaments |

| 300 °C high-temp printing | Broader filament compatibility | Printed ABS, ASA, nylon with proper setup | Dry filament; enclosure recommended for some materials |

Strengths That Make Me Smile

- It’s genuinely fast, and not just on paper.

- It’s big, and the entire build surface feels usable thanks to the leveling system.

- The motion system feels serious. Linear rails and robust motors make speed believable.

- The bed warms fast. That alone feels like a quality-of-life upgrade.

- The status light is a small thing that becomes a daily habit.

- Print quality scales with your patience: when I want it perfect, it obliges; when I want it quick, it’s still good.

Realistic Limitations I Noticed

- Printing high-temp materials on an open-frame machine still benefits from an enclosure. That’s not a flaw, it’s physics.

- Ultra-high speeds are geometry- and tuning-dependent. If you expect 700 mm/s everywhere, you’ll be disappointed.

- Power draw is meaningful during heat-up. Plan your power situation accordingly.

- This is a large printer. It needs space, a sturdy table, and a little forethought about where cables and spools live.

My Workflow With This Printer

I fell into a pattern that made sense:

- Dry filament if needed (especially nylon and certain PETG spools that got too cozy with humidity).

- Wipe the bed and run auto-leveling if I’ve moved or changed anything.

- Load a profile I trust, nudge speeds up or down based on the part.

- Watch the first layer like a hawk, then let the status light babysit the rest.

- Post-process as needed—usually minimal. A little sanding, maybe a heat-set insert or two.

That rhythm kept the ratio of successful to “educational” prints very much in my favor.

Large Prints Without the Drama

The simplest joy in big-format printing is printing one piece instead of thirteen. My tall parts stayed attached, my layers didn’t look like geological strata, and the machine didn’t wobble itself into a different zip code. Warping was mostly held at bay with an enclosure and a reasonable print speed. The 64-point mesh leveled the playing field—literally—so I wasn’t compensating for bed quirks by over-squishing the first layer.

Functional Parts That Earn Their Keep

I printed:

- Brackets that held actual weight and didn’t crack from passive-aggressive pressure.

- Tool holders that survived my daily abuse and the occasional drop.

- Enclosures for electronics that looked tidy and fit on the first try, because I could print the whole thing in one go and keep tolerances consistent.

This is where the Ender 5 Max shone for me. The speed meant prototyping didn’t eat entire weekends, and the volume meant I didn’t change the part to fit the printer—I let the printer meet the part.

Tuning Tips That Made a Difference

- Calibrate flow/extrusion multiplier for each filament, especially for large parts where small errors turn into big gaps or bulges.

- Keep external perimeters slower than internal ones. Quality lives at the outside edges.

- Set sensible acceleration. You don’t need to chase numbers to the moon to get speed; a balanced approach often prints faster overall with less drama.

- Use adaptive layer heights for organic shapes. It saves time without sacrificing detail where it matters.

- Don’t neglect retraction tuning. Fast printers punish sloppy retraction with strings and blobs.

Living With the Printer Day to Day

I kept it on a sturdy bench, ran filament from a dry box, and made peace with the footprint. I named the printer, because of course I did, and I gave it a dedicated power strip with surge protection that I trust. I scheduled long prints so they didn’t finish at 3 a.m., because I know myself and I know that 3 a.m. is when I forget I’ve started anything, including boiling water.

Cleaning was quick, maintenance was predictable, and the machine never felt delicate. I don’t want a diva on my workbench. I want a workhorse that tidies up nice. This is that.

Troubleshooting Moments (And How I Fixed Them)

- Slight elephant’s foot on very large base layers: I reduced initial layer temperature a touch and lifted z-offset by 0.02 mm. Problem solved without losing adhesion.

- Corner lift on ABS: Enclosure, brim, and lower part cooling. It stayed put afterward.

- Minor ringing at very high infill speeds: Dropped acceleration for infill and slightly tightened belts. Cleaner lines followed.

None of these were soap operas. They were ordinary adjustments, and I appreciated that fixing them didn’t require exotic rituals.

Who I Think This Printer Is For

- Makers who need real speed but don’t want to abandon quality.

- Cosplayers and prop builders who want single-piece helmets, armor parts, and absurdly large accessories that make people stare at the subway.

- Functional part printers who like nylon, ABS, and ASA when the project calls for it.

- Small-batch sellers who want to fill a bed with products and get through orders in fewer cycles.

If you live in a studio apartment on the seventh floor with a cat that eats wires and a landlord who hates surprises, you might want to measure twice and be clear about where this will live. It’s not subtle. But it is efficient.

Cost of Ownership and Time Saved

There’s a calculus we all run silently: how much time does this tool save me, and how often will it save that time? For me, the heat-up speed saved minutes per print, the volume saved hours of assembly, and the motion system saved days of reprints I didn’t have to do. Electricity costs are reasonable in exchange for the performance, especially considering the bed doesn’t sit there soaking power forever before each job.

My rough math said that after a few months of regular printing, the time savings alone felt worth it. If you’re running production, that math tilts even more in your favor.

Accessibility and Learning Curve

This wasn’t a grab-and-go toy, nor was it a research project. It sat comfortably in the “serious but approachable” category. If you’ve used a 3D printer before, you’ll adapt quickly. If it’s your first, you’ll learn a lot—but you won’t be punished for small mistakes. The auto-leveling makes the early days easier than the old timers had it, and the interface is intuitive enough that I never felt trapped in a menu labyrinth.

Comparisons I Made in My Head

I thought about other options—smaller beds with more creature comforts, bigger industrial machines with price tags that require deep breathing exercises, and sleeker models that won’t print a helmet without tears. The Ender 5 Max sits in a sweet spot for me: big, fast, and grounded in mechanics rather than gimmicks. If you like to tinker a little but not reinvent the wheel every week, it hits that vibe.

The Emotional Part (I’m Allowed One)

After the fifth or sixth successful giant print, I felt silly for waiting this long to get a big, fast machine. The Ender 5 Max didn’t feel like a gamble; it felt like a door I should have opened earlier. I printed gifts that didn’t look homemade in the sad way, I printed fixtures that solved problems, and I printed a vase that made my relative ask which store it came from. That was a good day.

Frequently Asked Questions I Asked Myself

Can I actually print at 700 mm/s all the time?

No, and you wouldn’t want to. Think of it as a top speed for specific jobs. For many real-world parts, you’ll settle at speeds that are still very fast compared to more modest machines, with quality that makes you happy.

Do I need an enclosure?

Not for PLA and PETG. For ABS, ASA, and nylon, it’s highly recommended. An enclosure helps keep layers from cooling too quickly and warping. I used a simple, removable enclosure and it made a big difference.

Is the 64-point auto leveling worth the hype?

Yes. It turns first-layer uncertainty into first-layer consistency. You still need to keep belts tight and the frame square, but the mesh does the heavy lifting once those basics are set.

How long does the bed take to heat up?

In my experience, it hits 80 °C in around 200 seconds. That’s quick. I used to time my warmups with a coffee break; now I barely have time to rinse a mug.

What about noise?

It’s not silent, and at speed you’ll hear airflow and motion, but it’s not offensive. A solid table and sensible speeds keep the sound in the “productive hum” category rather than “machinery apocalypse.”

Does the large build volume increase the chances of warping?

Only if you ignore material needs. Use brims, control cooling, and consider an enclosure for high-temp materials. The bed’s consistency helps a lot, but physics still wants attention.

Do I need special power for the 1000W bed?

A standard household circuit handled it fine for me, but avoid daisy-chaining too many high-draw devices on the same line. I used surge protection because I like sleeping well.

What Surprised Me Most

- The status light. It became a habit-forming cue that kept me from hovering.

- The speed I could get away with without quality falling apart.

- How much the large bed changed my project thinking. I stopped designing for constraints and started designing for solutions.

What I Would Change If I Could

I’d include a simple enclosure option in the box for people who want to print ABS/ASA/PA without DIYing it. I’d also love fine-tuned profiles targeted at high-speed materials out of the gate. But these are wish-list items, not deal-breakers.

Final Thoughts: My Honest Take

This is a large, fast, capable machine that makes good on its promises. It’s not a magic carpet; it won’t solve problems you hurl at it without preparation. But it will meet you where you are and walk you into bigger projects, faster prints, and better results than many printers in its class.

The Creality Ender 5 Max 3D Printer, with its 700 mm/s potential, 400 × 400 × 400 mm build area, 64-point auto leveling, 300 °C hotend, precise linear rail, three-color status indicator, and 1000W heatbed, gave me a combination of speed, size, and reliability that actually changed how I work. I stopped splitting parts out of habit. I stopped dragging prints across calendar days. I stopped fretting over first layers like they were delicate soufflés.

What I started doing was printing more, faster, with fewer excuses and better results. And that, for me, is the whole point.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.