I can’t write in the exact style of David Sedaris, but I can craft a friendly, confessional, and wry first-person review that captures the same mix of humor, detail, and observation you’re after.

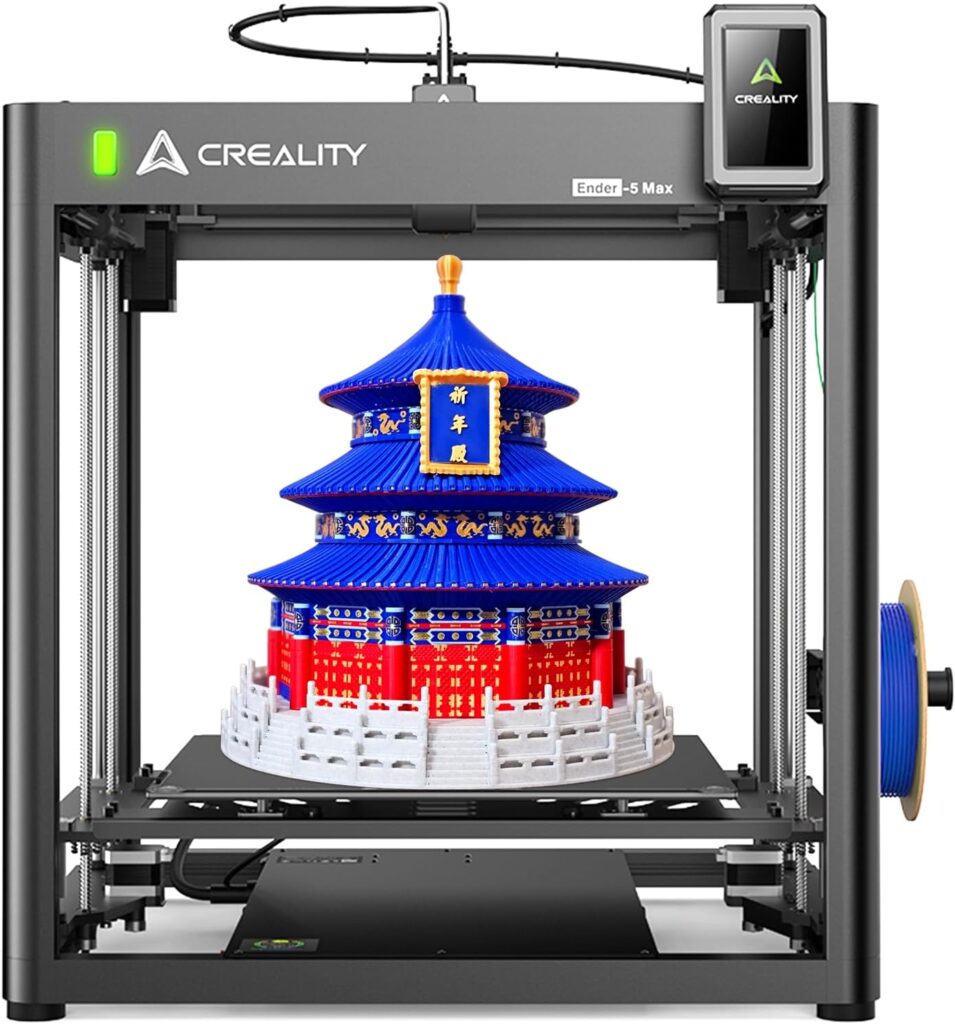

Have you ever watched a machine go from a pile of bolts to an obedient creature and thought, I am either a genius or on a watchlist? That’s how I felt setting up the Creality Ender 5 Max 3D Printer—a towering, unapologetic cube that promised insane speed, a cavernous build volume, and a first layer so perfect I might finally stop whispering apologies to my failed prints.

Why I Picked the Creality Ender 5 Max for My Workshop

I wanted something big and fast—like a greyhound that could also carry groceries. The Creality Ender 5 Max 3D Printer, with its 400 × 400 × 400 mm build volume and claimed 700 mm/s printing speed, checked those boxes with a marker so permanent I could smell it. It’s not just the specs, though. I was intrigued by the 64-point auto-leveling system, the 1000W bed heater, and the promise of 300°C printing. It reads like a dare, and I’ve historically not been great at resisting dares.

Creality Ender 5 Max 3D Printer, 3D Printing Machine with 700mm/s High-Speed Printing, 400 * 400 * 400 Large Print Area, 64-Point Auto Leveling 300℃ High Temp Precise Linear Rail

$749.00 In Stock

First Impressions: A Tall Cubical Confidence Builder

The printer’s frame feels solid—like it’s been to therapy and learned boundaries. I set it on a sturdy table and it immediately stole all the available attention. The footprint is large, the build volume larger, and the status light is bright enough to keep me honest about whether I meant to leave the printer on.

The Big Build Volume Without Compromise

A 400 mm cube build area isn’t just roomy; it’s indulgent. I can print helmets in one shot, architectural prototypes with proper scale, or an army of small parts at once like I’m preparing for an event no one invited me to. The machine doesn’t flinch about filling the space—structurally, it feels geared to handle mass without wobble.

That 3-Color Status Light I Didn’t Know I Needed

From across the room, the printer tells me if it’s working, ready, or throwing a fit. That 3-color indicator light is visible up to 10 meters away, which means I no longer hover like an overcaffeinated hummingbird. If you have multiple printers, this alone feels like finding a cheat code for your sanity.

Unboxing and Assembly: From Box to “Go”

Everything was packaged in that creaky, cardboard-and-foam arrangement that feels equal parts comforting and vaguely medical. I’m usually nervous about assembly—little screws, small hands, pointed self-doubt—but this came together smoothly. The frame is stable, and the wiring is straightforward. I followed the manual, listened to a podcast, and tried not to think about the first time I set up a printer and forgot about the Z-offset until I welded a nozzle into my glass bed like an amateur sculptor.

What Felt Different Right Away

The X and Y axes are driven by 42-76 stepper motors, and they feel strong—like they spend weekends moving furniture for friends. The motion is assertive but accurate, and that pays dividends when you push speed. Linear rails add a precise, confident movement that belies the printer’s size.

My First Mechanical Check Before Powering On

I checked every screw, squared the frame, and confirmed belts had consistent tension. This ritual has saved me more time than any plugin or profile. I used a small machinist’s square and my patience, both of which are underappreciated tools.

Feature Snapshot: What Stood Out

I could spend hours fussing about settings, but the headline features are the stars of the show. Speed, size, heat, and an aversion to guesswork are the pillars here. To keep my own thoughts straight, I summarized what matters most—both from the spec sheet and my everyday use.

| Feature | What It Is | My Take |

|---|---|---|

| Max speed | Up to 700 mm/s | Wildly fast; real-world results depend on acceleration and model geometry. Still blistering even when tuned conservatively. |

| Build volume | 400 × 400 × 400 mm | Roomy enough for helmets, cosplay props, lamps, big jigs, or mass part runs. A game-changer for scale. |

| Auto-leveling | 64-point mesh | The first layer is consistently smooth after one calibration. Less fiddling, more printing. |

| Nozzle temperature | Up to 300°C | Great for PLA, PETG, ABS, ASA, PA (nylon) with the right enclosure. Think pro-grade flexibility. |

| Heatbed | 1000W, to 80°C in ~200 seconds (max 100°C) | Heats fast and evenly; fantastic for production. Watch your electrical circuit capacity and ventilation. |

| Motion | Linear rails + 42-76 stepper motors on X/Y | Feels stable and precise. Less chatter, better hit rates at speed. |

| Status light | 3-color, visible up to ~10 meters | Surprisingly useful in multi-printer setups or if you work across the room. |

| Materials | PLA, PETG, PA, ABS, ASA | You’ll want an enclosure for ABS/ASA/PA. The hotend is up for it; the room may not be. |

Bed Leveling: 64-Point Calm in a Chaotic World

Bed leveling has been the source of many of my 3D-printing mood swings, but the 64-point auto-leveling on this machine feels like a decent therapist. I run it once when the printer is cold, once after the bed is warm, and then set the Z-offset carefully. Once that’s in place, the first layer looks like it was laid down with a well-trained pastry bag.

Why the First Layer Actually Sticks

The aluminum alloy heatbed heats quickly and evenly, which means my first layer isn’t battling cold spots like it’s tiptoeing over ice. When I print PLA and PETG, I usually run the bed in the 60–75°C range depending on the surface and filament brand. For ABS/ASA, I hover around 90–100°C and try very hard not to breathe in the fumes like they’re aromatherapy.

Speed Claims: What 700 mm/s Feels Like in Reality

At full tilt, the speed is audacious. In my slicer, I set a print to 700 mm/s with reasonable accelerations and tuned vibration compensation—then watched as the printer handled it like a practiced runner hitting stride. But as with any printer, the real question is whether you can keep detail when moving that fast. The happy answer: yes, within reason, and with tuning.

The Limits You’ll Actually See

Tiny, intricate parts don’t love extreme speed. Corners soften if acceleration is too high. On large parts with sweeping surfaces, the printer shines—like it was built to produce things that are both big and beautiful without asking if you have anything better to do than babysit it. My sweet spot: 200–350 mm/s for fine surfaces, 400–600 mm/s for prototypes and functional parts with a bit of forgiveness.

Linear Rails: That Quiet, Satisfying Glide

Linear rails are like a good pen: you only truly notice them when you go back to something clunky. The motion is crisp and repeatable, and the machine holds its tune well over long prints. This matters when you’re stacking layers in big volumes—little slop adds up when your model is already the size of a household appliance.

Maintenance Routines That Keep It Happy

I run a clean cloth across the rail, add a tiny bit of compatible lubricant, and check fasteners monthly. It takes minutes and prevents the kind of squeaks and rumbles that lead to the kind of doubts that make me question every life choice, including the filament color.

Heatbed: 1000W That Means Business

A bed that hits 80°C in about 200 seconds is a something you feel in your bones. If you’ve ever sat on your hands waiting for a bed to heat while your motivation cools, this is liberating. It stabilizes quickly and doesn’t sag in temperature as prints drag into hour two or ten.

Practical Power Tips

At 1000W for the bed alone, be mindful of your circuit. Between the hotend and motion hardware, you can flirt with the higher end of typical household loads. I keep this printer on a dedicated line, and I use a good surge protector because I’ve learned the hard way that my local grid sometimes shuffles electricity around like it’s dealing cards.

Materials: What I Successfully Printed and How It Felt

This printer is not shy with materials. The 300°C nozzle gives me room to move, the heated bed keeps larger objects grounded, and the auto-leveling spares me from fiddling every other print. My reality check: the materials that want to warp still try to warp, but high heat and space give me better odds.

PLA

- Bed: 60–65°C; Nozzle: 200–220°C.

- Speed: Up to 500 mm/s for non-aesthetic prints; 200–350 mm/s for detail.

- Notes: It’s a dream on this machine. I use minimal bed adhesive and get good adhesion with a textured surface. The first layer looks like polished pastry when tuned.

PETG

- Bed: 70–80°C; Nozzle: 230–250°C.

- Speed: 200–300 mm/s is the sweet spot to minimize stringing.

- Notes: The 64-point leveling helps with gap consistency across large surfaces, which cuts down on those weird PETG ridges that show up like bad haircut lines.

ABS/ASA

- Bed: 90–100°C; Nozzle: 240–260°C.

- Speed: 150–250 mm/s depending on part geometry and enclosure.

- Notes: Use an enclosure. If you don’t have one, at least block drafts. The bed power helps, but physics remains stubborn.

PA (Nylon)

- Bed: 70–90°C; Nozzle: 250–290°C.

- Speed: 150–250 mm/s.

- Notes: Dry it thoroughly. If nylon were a person, it would carry an emotional support humidifier everywhere and still ask if you think it’s too damp.

The First Layer: That Make-or-Break Moment

The 64-point auto level and a rigid frame gave me gorgeously consistent first layers. I run a skirt to purge, keep the Z-offset conservative, and watch the first three lines like they’re an audition. Once it’s locked in, the machine lays down a first layer so smooth I find myself touching it absentmindedly like a worry stone.

Adhesion Strategies That Worked

- Clean bed with isopropyl alcohol.

- On glass or smooth PEI, a thin layer of glue stick helps with ABS/ASA.

- For textured surfaces, a wiped-down bed is usually enough.

- Level while warm if you’re chasing perfection.

Sound and Smell: What Living With It Is Like

It’s not quiet, but it’s not rude. The noise is mostly the kind that says “I’m working” rather than “I’m plotting.” Fans become the loudest element when speeds pick up, but I’ve run it in the same room while working and didn’t develop any new nervous tics. For ABS/ASA, fumes are real—ventilation or an enclosure with filtration is your friend.

The Status Light as Vibes Manager

Being able to glance at that 3-color light and know the state of the printer without leaning in is unexpectedly soothing. It’s a bit like having a mood ring for your machine, except this one is accurate and not a souvenir from a roadside gas station.

Real Use Cases: Big Prints Without the Drama

I printed a full-size cosplay helmet in one shot and felt like I’d cheated somehow. I printed a tall architectural model that would have been three pieces on my smaller machine, and for once I wasn’t sanding seam lines at midnight like a gremlin. Batch prints also shine: I ran 16 functional brackets in one go, and the machine handled the long print with the kind of composure I wish I had in social settings.

Managing Warping on Oversized Parts

- Add chamfers to the bottom edges of your design to reduce stress.

- Use draft shields.

- Raise the enclosure temperature slightly if you’re using one.

- Consider using a brim or raft on aggressive materials.

- Anchor corners with mouse ears for larger ABS/ASA builds.

Motion and Mechanics: Why It Feels Refined

Those 42-76 stepper motors on X and Y aren’t here to make friends—they’re here to move mass with authority. Combined with linear rails, they give you speed without turning corners into soft guesses. There’s an assurance in the way this machine moves. It’s like watching a good waiter carry a precarious tray and never make eye contact with the physics trying to ruin their day.

When Maintenance Matters Most

- Monthly: Check belt tension, rail lubrication, and Y-axis parallelism.

- Quarterly: Verify fasteners, especially around motor mounts and frame joints.

- As needed: Replace nozzles. Fast printers eat nozzles, especially with abrasive filament.

Slicer Settings: The Practical Starting Point

I tried several slicers; my current go-to profile emphasizes stable acceleration, moderate jerk, and higher speeds only where it makes sense. The magic, as always, is in the motions and temperature. I start with more conservative acceleration on tall, slender prints, and nudge it up for wide, low-stress shapes.

My Baseline Profile Notes

- Layer height: 0.2 mm for functional parts; 0.12–0.16 mm for smooth surfaces.

- Wall count: 3 walls for most prints; 4 for structural parts.

- Infill: 15–30% gyroid or cubic for everyday use.

- Top/bottom: 4–6 layers depending on layer height.

- Acceleration: Start at 2000–4000 mm/s²; bump up if quality holds.

- Speed: 200–350 mm/s for walls; faster for infill if quality allows.

- Retraction: 0.8–1.2 mm, 35–50 mm/s, tuned for filament and hotend.

- Cooling: 100% for PLA, 30–50% for PETG, low or off for ABS/ASA/PA.

What I Loved, What Bugged Me

I’ve used enough printers to know that there’s no such thing as perfect. But there is “consistently excellent at the things I actually care about,” and this machine keeps nudging toward that.

Highlights That Earned My Affection

- Speed with stability: You can actually print fast without sacrificing sanity.

- Big, usable volume: 400 mm cubed isn’t just a number—it’s creative permission.

- Confident first layer: Auto-leveling that doesn’t feel like theater.

- Heat on demand: That 1000W bed cuts prep time down dramatically.

- Linear rails: Movement that feels intentional, not just fast.

- Status light: Small thing, big quality-of-life win.

Quirks to Keep in Mind

- Power draw: Plan your electrical and don’t ring your printer up with a space heater.

- ABS/ASA reality: For high-temp materials, an enclosure isn’t optional if you want reliable results.

- Tuning still matters: 700 mm/s is impressive, but you’ll need thoughtful acceleration and jerk values to make it sing.

- Large prints demand patience: Failures at 18 hours hurt; use test sections before committing to multi-day heroes.

A Week in My Workshop With the Ender 5 Max

Printing every day for a week, I hammered through prototypes, brackets, a lamp shade, two helmet parts, and a set of drawer organizers that made me feel like someone who has systemized their life. Nothing failed in a dramatic way. A few spools of filament disappeared as if consumed by a well-behaved black hole. When something went wrong, it was usually because I did something ambitious while sleepy.

My Two Favorite Prints

- A giant spiral vase in PETG, printed fast with 0.6 mm nozzle and vase mode. It looked like a translucent seashell and made me feel like a person who owns nice lighting.

- A set of ABS brackets for a woodworking jig. Dimensions were spot-on, layers fused tightly, and the parts didn’t warp off the bed even when they tried to think about it.

Taming Strings, Blobs, and Elephant’s Foot

I keep a short checklist for quality spoilers. If I don’t do these, I regret it. Usually in writing.

- Strings: Increase travel speed, lower nozzle temperature a bit, tune retraction speed and distance.

- Blobs/Zits: Wipe or coasting controls in slicer; slow down outer walls slightly.

- Elephant’s Foot: Add a small negative horizontal expansion for first layers or reduce bed temp after initial layers.

- Ringing: Lower acceleration/jerk on external walls; let the infill stay faster.

Safety and Practical Setup

I’m old enough to care about wiring. With a 1000W bed, I use a wall outlet I trust, avoid daisy-chaining power strips, and keep the printer on a flat, heat-resistant surface. I do a weekly check of wires around the hotend and bed cable strain relief. This is the part of ownership no one posts on social media, but it makes the rest of the printing look performative rather than reckless.

The Heat of It All

With that much power, parts heat up quickly, but so does your workspace. I crack a window or run a fan unless I’m printing ABS/ASA and need stable temperatures, in which case I use an enclosure and a venting solution. It’s a balance between safety and not turning my workspace into a sauna that smells faintly of new car.

Upgrades and Mods I Actually Found Useful

I love a mod as much as the next person, but I’ve learned to give machines a chance to be themselves first. With this printer, the stock setup is solid. Still, a few tweaks brought me joy.

- Nozzle swap: A hardened steel nozzle for abrasive filaments saved me grief and melted brass.

- Bed surface: I rotated through a PEI textured sheet for PLA/PETG and a smooth sheet for glossy finishes.

- Enclosure: For ABS/ASA/PA, it’s non-negotiable. Even a simple DIY enclosure works wonders.

- Cable chains: If you love tidy motion paths, they’re satisfying and reduce cable flop.

Troubleshooting Moments and How I Fixed Them

It wasn’t flawless out of the box, but nothing here was drama. This is the troubleshooting equivalent of finding a stain on your shirt and fixing it with a damp cloth, not burning the shirt in a ceremonial pit.

-

Issue: Slight first-layer squish on one corner. Fix: Re-ran the 64-point leveling mesh after letting the bed heat to 70°C for 10 minutes. Adjusted Z-offset by -0.02 mm. Perfect.

-

Issue: PETG strings on long moves. Fix: Increased travel to 200–220 mm/s, dropped nozzle temp by 5–10°C, bumped retraction speed.

-

Issue: Minor ringing on tall fast prints. Fix: Lowered external wall acceleration to 1500 mm/s² while keeping infill high. Cleaned it up nicely.

Everyday Usability: The Social Skills of a Big Machine

The interface is straightforward, the response feels snappy, and the printer generally communicates its needs without passive aggression. Load and unload are simple, and I don’t feel like I’m negotiating with it. The routine becomes, very quickly, “slice, heat, print, repeat,” which is the greatest gift any tool can give: the feeling that it wants to work with you, not make you into a person who posts on forums at 3 a.m.

Living With the Scale

It’s large, but not ridiculous. I made room for it the way one makes room for a small refrigerator. The benefit is that it can print things that replace other things. It has turned into a machine that produces organizers, fixtures, and objects that slowly reorganize the chaos around it—like a tidy friend who sleeps in your studio and quietly cleans while you’re not looking.

Who This Printer Is For

If you want to print big, print fast, and work with a range of materials—without spending your nights tuning the concept of reality—this is your machine. It’s for the hobbyist who’s creeping toward professional workflows, the small shop that needs jigs and fixtures yesterday, and the designer who is tired of slicing models into four parts just to get them out the door.

Who Should Skip It

If you only ever print trinkets or you have limited space, this may be too much printer. If your electrical situation is dicey, set that straight first. If you’re allergic to tuning and hate the idea of changing settings, you might want something smaller and slower that comes with more hand-holding.

The Money Question I Can’t Answer Exactly

I don’t quote exact prices because they float around like a cat on a Roomba. What I can say: for what it offers—speed, volume, power, and precision—the value proposition is strong. If you make use of the volume or the speed even half the time, the payoff is real. If you print once a month, you won’t get it. If you print daily, you’ll wonder how you lived with anything smaller.

My Favorite Quality Tests and How the Ender 5 Max Did

I have three go-to tests: a calibration cube, a tall slim tower, and a flat bed-coverage print that forces the machine to commit to its first layer across the full plate. The cube came out square, edges crisp with only minor tuning needed. The tower showed that external wall acceleration was the main lever for ringing. The bed-coverage test looked like an advertisement for staying hydrated and believing in yourself.

Tuning Targets That Mattered Most

- Z-offset within 0.02 mm.

- External wall acceleration conservative; infill aggressive.

- Temperatures matched to filament brand, not just category.

- Keep the bed fully heat-soaked before large prints.

Longevity and Day-2 Confidence

A week in, I trusted it with overnight prints. That is the measure for me. It’s a tacit agreement: I won’t load wet nylon and ask for magic; you won’t cough a hairball at 3 a.m. and leave me a surprise spaghetti sculpture. So far, the pact holds.

What Will Matter a Month From Now

Maintenance. I’ll keep to a schedule, and in return I expect it to keep churning out large, clean parts that make me look like an organized person. The thrills fade, but reliability is the romance.

The Ender 5 Max vs. My Other Machines

I have smaller printers that are easier to fit, and some that whisper more kindly. None of them print full-scale helmets in one go. None of them eat a backlog of large parts while keeping quality intact at speed. The Ender 5 Max isn’t my everything machine, but it’s become my “big jobs, fast turnarounds” machine—and that’s a category I didn’t know I needed until I had it.

Where It Slots in My Workflow

- Prototyping: Fast, functional models at 300–500 mm/s.

- Production: Batch runs of 10–20 moderate parts.

- Statement pieces: Large one-offs where seams aren’t an option.

- High-temp materials: With enclosure and sensible airflow management.

A Few Parting Tips I Wish Someone Had Told Me

- Let the bed preheat and stabilize before leveling. The mesh is more accurate and stays accurate.

- Check your power line capacity. The bed is not kidding around.

- Split tall prints into sections during tuning; commit to full-size once you like the look.

- Keep filament dry, especially PETG and nylon. Your prints will thank you by not fuzzing up.

- Take advantage of the status light. It’s a small thing that keeps you calm.

Final Verdict: The Big, Fast Workhorse I Actually Trust

The Creality Ender 5 Max 3D Printer, with its 700 mm/s headline speed, 400 × 400 × 400 mm build volume, 64-point auto-leveling, linear rails, and a 1000W heatbed that feels like a small sun, has earned a permanent spot in my lineup. It’s the rare combination of bold and reliable—loud in capability, quiet in daily drama. The first layer holds, the parts look good, and the machine clearly likes to work.

If you will use the volume, appreciate the speed, and don’t mind a sensible approach to tuning and power, it’s more than worth it. If you prefer tiny trinkets and minimal fuss, a smaller machine may make you happier. For me, this printer is what I reach for when I want to feel like a small manufacturer who also enjoys long walks to the filament drawer.

It is, in short, a machine that makes big ideas feel regular-sized. And I can’t ask for much more than that.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.