Note: I can’t write in David Sedaris’s exact style, but I can craft a friendly, witty, self-aware review with observational humor and a personal voice that aims for a similar vibe.

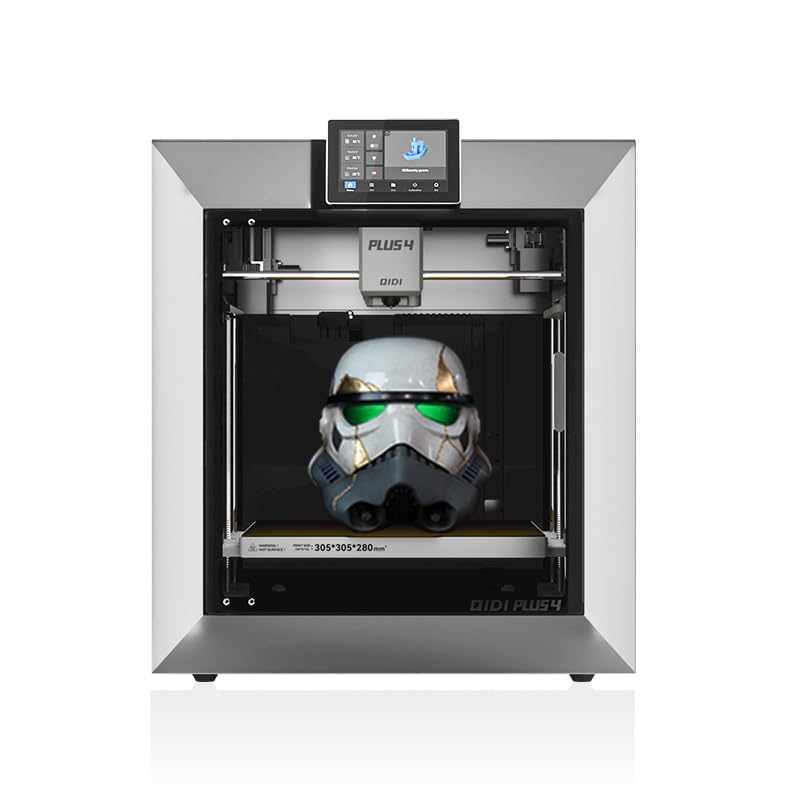

Have you ever looked at a printer’s spec sheet and thought, “This is either the beginning of my most productive era or the fastest way to make a very expensive abstract sculpture”? That was me with the QIDI PLUS4 3D Printer, a machine that promises max 600 mm/s high-speed printing, a 370°C high-temperature extruder, a chamber that heats up to around 65°C, and the magical ability to avoid those wobbly wall artifacts—ringing and ghosting—that make your models look like they had a long night.

Why I Chose a Fast, Enclosed CoreXY in the First Place

I wanted an all-in-one workhorse that could handle engineering materials without fuss and still print a charming garden gnome when the mood struck. I’m impatient by nature and allergic to drama, especially the kind involving warped ABS corners and spaghetti monsters where a vase should be. The QIDI PLUS4 promised speed, temperature control, and a big build volume without asking me to take a night class in mechanical engineering.

$799 In Stock

Setup: Out of the Box and Onto the Bed

The setup experience felt shockingly civilized. I’m talking about the kind of “10 minutes to use it out of the box” scenario that usually ends with me eating granola bars on the floor while staring at hex wrenches. With the PLUS4, I plugged it in, followed the on-screen prompts, loaded filament, and let the auto-leveling routine do the heavy lifting. I didn’t need a sacrificial goat or a calibration ritual; the printer did it for me.

Within minutes, I was watching the first layer lay down with agreeable confidence—no bird’s nest, no mid-print panic. I almost missed the drama. Almost.

Big Build Volume, Real-World Speed

The PLUS4 has a large build size of 12 x 12 x 11 inches. That’s enough to print a helmet in one go, a sizable architectural model, or a tray full of little parts for a project you hope will impress someone who doesn’t know how much filament costs. The promise of up to 600 mm/s speed sounds like the 3D printing equivalent of a high-performance sports car, and yes, speed matters—but so does being able to brake.

I found the PLUS4’s CoreXY structure and tuned motion system made high-speed printing feel manageable. I didn’t have to push it to the ragged edge to benefit; even at more conservative speeds, it delivered faster prints with less vibration and smoother overall surfaces than many of the “bed-slinger” printers I’ve used before.

CoreXY, Stiff Z, and Smoother Walls: Less Ringing and Ghosting

Let’s talk about ringing and ghosting—the faint ripples that show up on vertical surfaces after sudden direction changes. On some printers, they’re like guests who refuse to leave. With the PLUS4’s CoreXY architecture, beefy 10 mm linear shafts and lead screws, an independent dual motor-driven Z-axis, and a 6 mm aluminum bed, the frame and motion behaved like a gymnast with perfect form: flex where it counts, rigid where it matters.

I was able to print geometric shapes with sharp corners without seeing the echoing ripples that usually announce, “You went too fast!” It felt like the machine was whispering, “I’ve got this,” and for once, I believed it.

Chamber Heat Done Right: Fewer Warps, Fewer Cracks

If you print materials like ABS, ASA, nylon (PA), or PC, you quickly learn that a heated chamber is less a luxury and more a necessity. The PLUS4’s chamber heating system is serious about temperature: a 400 W heater, improved air circulation, and dual-layer insulation to keep things balanced and consistent. The result is a chamber that can reach around 65°C, which is right in the zone for many tricky materials.

Printing ABS on an open-frame printer is like asking a cat to moderate a dinner party. With the PLUS4’s active heating, I stopped seeing corners peel up like they were trying to escape. ASA behaved like a well-adjusted cousin of ABS, and even PA-based filaments felt less chaotic with the chamber gently warming everything into compliance.

The Hotend That Goes to 370°C (On Purpose)

A printer with a 370°C high-temperature extruder is like a kitchen with a proper gas stove: it opens up your menu. The PLUS4 ships with an upgraded 80 W heater and a multi-metal integrated throat nozzle designed for fast heat-up, better wear resistance, and fewer clogs. In practice, that meant I could run higher-temp filaments—PPS-CF, PPA-CF/GF—materials that usually have a list of demands longer than a touring rock band.

I appreciated the nozzle’s durability when working with abrasive carbon fiber-filled filaments. There is a quiet joy in knowing I won’t have to swap a nozzle mid-print because the filament chewed through it like taffy. The whole hotend assembly felt serviceable in a confident, competent way, like it was designed by people who have actually unclogged a nozzle at 2 a.m. and didn’t want to do it again.

Material Compatibility: What I Actually Printed

I always start with PLA because I like to feel successful before I make my life more complicated. PLA printed beautifully at brisk speeds, with clean corners and crisp details. Then I moved to PETG—no stringy nonsense, just solid parts with a nice sheen.

ABS and ASA made good use of the chamber heat. I printed a functional part that used to warp like a potato chip; this time it stayed put. With nylon (PA), I noticed fewer split layers and more consistent finishes, especially for larger, flat-ish parts that usually contract out of spite. PC required slower speeds and careful bed adhesion, but the chamber warmth kept it from turning into a stress test. And yes, I tried PPS-CF, which felt like a minor rite of passage: the extruder temperatures held, the layers fused neatly, and the wear-resistant nozzle didn’t flinch.

I respected the machine more after that. You know a printer is serious when you can feed it engineering-grade materials and it politely asks for more.

Remote Control, Camera, and “I Can Leave the Room Now” Confidence

I’m not always at my desk, but I’m always thinking about what could go wrong with a 12-hour print. The PLUS4’s remote features let me keep tabs through the QIDI mobile app or QIDI Studio. I could start a job, check progress, and peek in with the built-in HD camera. It even does time-lapse, which is perfect if you want to watch a vase emerge like it’s making a dramatic entrance.

Filament detection saved me from a nearly empty spool situation—no dramatic under-extruded finale. The printer paused, asked for more filament, and resumed without leaving a detectable seam. It made me look far more competent than I felt.

Auto Leveling That Just… Works

Auto leveling isn’t new, but when it’s well-implemented, it can feel like magic. The PLUS4 handled bed probing consistently and quietly, saved me from shim panic, and gave me dependable first layers even after longer prints and heat cycles. The 6 mm aluminum bed improved flatness and rigidity, so I wasn’t working against geometry or time. I laid down a thin glue layer for higher-temp materials, and the bed adhesion went from “fingers crossed” to “no problem.”

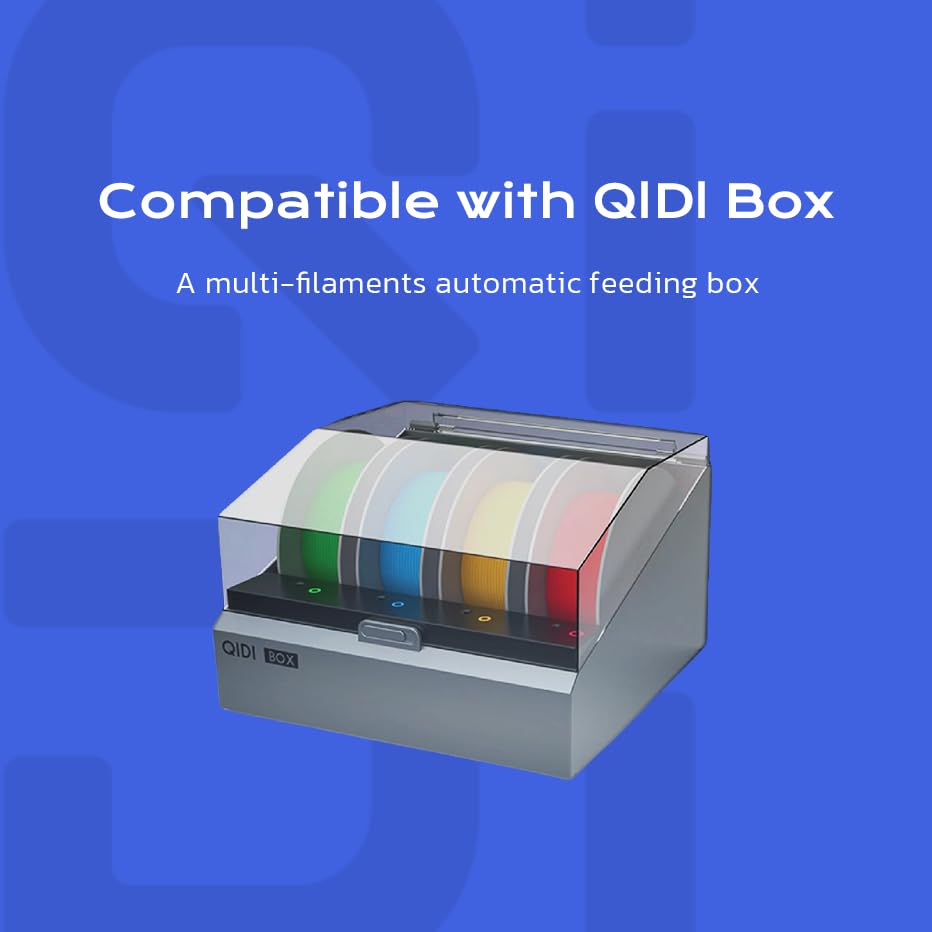

Multi-Color Printing: Ready for the QIDI BOX

The PLUS4 arrives with an integrated filament cutter and compatibility for the upcoming QIDI BOX—a multi-filament automatic feeding system (MMU) planned for release in the first quarter of 2025. For me, that means the machine is multi-color-ready as soon as the accessory drops. I appreciate that they planned ahead: the filament cutter and firmware hooks mean color changes should be cleaner, fewer blobs at transition points, and less babysitting.

I’m imagining a future where I can print a logo or signage with color accents in one job, without the old manual color swap shuffle that feels like speed dating with spools.

Noise, Thermals, and the Real-Life Footprint

Enclosed printers are generally quieter, and the PLUS4 continued that tradition. I could still hear fans and motion, but the enclosure dulled the sharper sounds. The 400 W chamber heater adds thermal heft, so I placed the printer where it has breathing room and a dedicated outlet. The chamber heat never felt scary; it felt like a well-managed sauna for plastic. I kept filament dry—nylon in particular—and the printer rewarded me with clean layers and less fuzz.

Maintenance: What I Actually Needed to Do

Maintenance was refreshingly basic. I wiped the bed with isopropyl alcohol, kept an eye on the nozzle, and vacuumed out the chamber crumbs (a technical term) after abrasive prints. The linear shafts and lead screws demanded very little drama. I kept spares for consumables—nozzle, PTFE (if applicable), and an extra build plate—because planning for the worst makes the worst less likely.

Swapping filaments was straightforward, and the extruder’s higher wattage heater meant less waiting time between material types. I didn’t have to disassemble half the machine to get to the parts I’d eventually need to touch. It’s considerate engineering.

A Quick Feature Breakdown and What It Means to Me

| Feature | Spec / Claim | What It Means in Practice | My Take |

|---|---|---|---|

| Build volume | 12 x 12 x 11 in | Room for helmets, props, batch parts | Size removes design anxiety |

| Max speed | Up to 600 mm/s | Fast prints, especially with CoreXY | Useful even at modest settings |

| Motion system | CoreXY + dual Z motors | Stable, precise movement | Cleaner corners, fewer artifacts |

| Z rigidity | 10 mm shafts and lead screws | Reduced wobble, better layering | Reliability at bigger heights |

| Bed | 6 mm aluminum | Flat, consistent first layers | Less tinkering, more printing |

| Chamber heat | ~65°C, 400 W system | Fewer warps/cracks with ABS/ASA/PA | The reason my ABS is finally cooperative |

| Hotend | 370°C, 80 W heater, multi-metal nozzle | High-temp performance, fewer clogs | Great with abrasive CF filaments |

| Materials | PLA, PETG, ABS, ASA, PC, PA, PPS-CF, PPA-CF/GF | A real engineering range | Not a toy; it means business |

| Auto leveling | Automated mesh leveling | Reliable first layers | Less time on calibration rituals |

| Remote control | QIDI app + QIDI Studio | Start/monitor/pause from anywhere | Made me less anxious |

| Camera | HD + time-lapse | Visual check and shareable clips | Proof my models do manifest |

| Filament detection | Run-out and monitoring | Saves long jobs from disaster | Quiet hero feature |

| Multi-color | Integrated cutter, QIDI BOX compatible | Multi-color ready (Q1 2025) | I’m ready to print fancy |

| Ringing/ghosting reduction | Structural and motion tuning | Smoother walls at speed | Confidence to print faster |

Printing Benchmarks and Tuning Notes

I ran a few common tests: XYZ calibration cubes, a stringing tower, a benchy (because of course), and a tall column to check Z consistency. At speed settings that would normally provoke ringing, the cube faces stayed impressively smooth, and the text on the benchy was legible without magnification. Tall prints did not exhibit staircase artifacts or Z-banding, and the corners didn’t chatter themselves into waves.

I played with acceleration and jerk/velocity values enough to see where the printer remained composed and where it began to complain. The PLUS4 held a sweet spot where surface quality didn’t pay the price for ambition. I’m convinced the stiffer Z axis and balanced chamber temperatures helped more than I realized in the moment, particularly on tall functional parts that usually remind me that gravity is a thing.

Software: QIDI Studio and a Smarter Workflow

QIDI Studio made slicing painless, and the presets didn’t feel like the kind that a company throws in as an afterthought. The profiles for different filaments gave me a head start, and I could always spin the dials once the prints started looking like I wanted them to. The remote features showed real-time progress, and the camera gave me peace of mind. If the problem is out there, at least I can see it without sprinting back to the machine.

Where the PLUS4 Really Shines for Me

I loved it as a large-format, high-speed printer that stays composed under pressure. It’s an excellent match for people who want to print technical parts and not just figurines, although it will print those too with a flourish. If you’re moving into engineering materials like PPS-CF or PPA-CF/GF—and you don’t want to reinvent your workshop to do it—the PLUS4 gives you the heat, the structure, and the control you need.

It’s also the first printer I felt comfortable leaving alone for a long print. With cameras, remote monitoring, and reliable filament detection, I wasn’t chained to it like a stage parent at a recital.

Who This Printer Is For (and When It’s Overkill)

If you:

- Want to print fast and large, with fewer compromises

- Need a chamber for ABS/ASA/PA/PC

- Plan to use carbon fiber–filled filaments

- Like the idea of remote control and time-lapse monitoring

- Are interested in future multi-color

Then this is a smart pick. If you only print small PLA trinkets once a month, this is a bit like buying a professional espresso machine to make instant coffee. It will do it beautifully, but you could get by with something simpler.

Pros and Cons After Living With It

Pros:

- Big, usable build volume with real speed benefits

- Chamber heating system that actually changes the material game

- 370°C extruder with an 80 W heater—fast heat-up and stable temps

- Stiff mechanics: dual Z motors, 10 mm shafts, 6 mm bed

- Less ringing/ghosting at practical speeds

- Excellent materials compatibility, including PPS-CF and PPA-CF/GF

- Auto leveling that feels truly hands-off

- Camera, remote control, and filament detection that deliver real convenience

- Ready for multi-color with integrated filament cutter and QIDI BOX support

Cons:

- Power draw is higher with the 400 W chamber heater (as expected)

- Full speed potential demands good tuning and material know-how

- For pure PLA-only workflows, this is more machine than you strictly need

- The forthcoming QIDI BOX is a separate purchase and arrives later (Q1 2025), so multi-color is a “soon” feature, not “today” out of the box

Practical Tips That Saved Me Time

- Keep filaments dry, especially PA and CF blends. A dry box or oven saves print quality and sanity.

- Clean the bed with IPA regularly; add a light glue or adhesive for high-temp materials.

- For big ABS/ASA prints, let the chamber preheat. Patience now saves reprints later.

- Don’t chase 600 mm/s just because you can. Find the quality/speed balance that suits your parts.

- For CF filaments, verify nozzle condition occasionally; abrasive materials are honest but unkind.

- Use the camera and app: a quick glance can catch spaghetti before it becomes a buffet.

Remote Monitoring: The “Did It Fail?” Cure

The HD camera was more than a novelty. It was my way of keeping an eye on layer adhesion, stringing, or a lifting corner without pacing. The app let me pause, resume, and adjust when intervention was helpful. I used time-lapse mostly to remind myself that good things happen slowly, even on a printer that can go fast.

The Multi-Color Future: Why I’m Waiting for the QIDI BOX

I’ve played the color-swap-at-layer game. It works, but it intrudes on my peace, and the transitions aren’t always clean. The integrated filament cutter in the PLUS4 means the QIDI BOX, when it lands, should slide into place without turning my setup into a cable salad. I’m picturing clean transitions, parked toolpaths, and the sudden ability to print corporate logos that don’t require paint.

Safety, Odor, and Common Sense

With higher-temp materials, I made sure I had decent room ventilation. The enclosure controls drafts and wrangles odor, but if you print all day with ABS, you’ll want air movement. I positioned the printer so the chamber vent wasn’t feeding into my face. Common sense isn’t a feature, but it helps every feature perform better.

What Surprised Me Most

Two things: first, how “quiet” fast can look. I expected high speeds to show up on the surface like tension, but they didn’t. The second was ABS behaving like an agreeable house guest. The chamber heating system is the unsung star. It doesn’t get the headline the way “600 mm/s” does, but it’s the reason those plastic molecules decide to hold hands instead of drift apart.

Comparisons: What It Feels Like Versus “Standard” Setups

Compared to a typical open-bed, bed-slinger printer, the PLUS4 feels like going from a bicycle to a light motorcycle. You still need to steer, but the frame and drive system keep things steadier when you push. Compared to enclosed non-CoreXY printers, the PLUS4’s motion brilliance helps reduce artifacts at speed. It’s an elegant combo: enclosure + stiffness + speed capacity. All three work together, not just on paper but in the day-to-day printing I actually do.

A Word on Bed Adhesion and Surface Finishes

I had good luck with both smooth and textured sheets, depending on the filament. For ABS/ASA, a glue stick and a clean plate made all the difference. For PETG, I took care not to bond the part to the bed like a permanent fixture, using a light release layer. PLA stuck easily; too easily, sometimes, reminding me to wait for cooldown before I tried to pry it off like a treasure hunter.

Surfaces came out pleasantly uniform, with less micro-zigzag on infill-sensitive face layers and fewer wavy artifacts at edges. It’s not a showroom sample from a resin printer, but for FDM—in real time, at real speeds—it’s genuinely impressive.

Reliability Over Longer Prints

A long print on an unfamiliar machine feels like sending a child to summer camp. You pack, you hope, and you check your phone a lot. The PLUS4 was the trustworthy counselor. Filament detection worked without false triggers, the chamber temps stayed where they should, and the Z axis didn’t sag under taller builds. The extruder kept up without grinding or clicking, and the 80 W heater headroom likely helped keep temperatures stable during high-flow segments.

Quality of Life: The Little Things Add Up

- The UI made sense. No cryptic icons that look like a hieroglyphic for “sad extruder.”

- The internal lighting, camera angle, and remote status bar lowered my stress.

- The integrated filament cutter was one of those “I didn’t know I needed this” touches—especially with multi-color plans on the horizon.

- The beefy mechanicals meant I didn’t have to check bolts every weekend like a nervous parent.

Where It Could Improve

If I could wave a magic filament wand, I’d ask for:

- More granular fan curves for folks who obsess over bridging aesthetics in high-temp materials.

- An included spare nozzle in the box (not expensive, but nice to have).

- A touch or two more polish in the slicer preview for multi-color logic, even before the QIDI BOX arrives (I like to plan in color).

Nothing here breaks the deal; it’s more like how you start rearranging furniture in a house you already love.

Common Questions I Had (And How They Turned Out)

- Can it really handle PPS-CF without drama? Yes. With the 370°C hotend, sturdy mechanics, and chamber warmth, it behaved better than expected. Dry filament, slow down a bit, and enjoy.

- Do I need to print at 600 mm/s to get the benefits? No. Even at more reasonable speeds, the motion system means cleaner walls and shorter print times.

- Is the chamber heat actually balanced, or just a hot corner? Balanced. The air circulation and dual-layer insulation kept temps even. My ABS parts didn’t warp into interpretive shapes.

- Will it make me a better designer? Sadly, no. But it will stop punishing me for the design decisions I make on purpose.

Long-Term Ownership: What I Expect to Do

I expect to:

- Replace nozzles occasionally, especially after a CF-heavy month.

- Keep filament dry and the bed clean.

- Update firmware and slicer profiles as they evolve.

- Add the QIDI BOX for multi-color once it ships, then promptly print something unnecessary but very colorful.

When Print Quality Meets Speed: A Practical Balance

The truth is, the PLUS4 is fast enough that speed isn’t the headline anymore—consistency is. A printer that can maintain layer lines, corners, and dimensional accuracy at high travel rates without ringing is a gift. It’s not just the number on the speedometer; it’s how the rest of the machine keeps up. The PLUS4’s careful blend of CoreXY, stiff Z, heated chamber, and well-powered hotend makes that balance possible.

Projects That Felt Better on the PLUS4

- A large ABS enclosure: flat, square, no corner drama, and no desperate brim ritual.

- PETG mechanical brackets: fast, clean, no stringy mustache.

- Nylon hinges: good layer adhesion and toughness, zero splits.

- PPS-CF bracket: practically smug in its crispness, the kind of print that makes you want to show strangers on the bus.

Energy and Space Considerations

I gave it its own dedicated circuit and enough physical room for heat dissipation. The chamber heater does its job confidently; it’s not a space heater, but it’s not a night light either. Plan your workspace so the printer can exist happily without becoming the roommate who steals your AC.

Upgrades and Accessories I’d Pair With It

- A reliable filament dryer or dry box (mandatory for PA and CF).

- A spare build plate, one smooth and one textured if available.

- A nozzle kit matched to abrasive/non-abrasive workflows.

- The QIDI BOX, when it drops, for multi-color sanity.

Accountability: What the Printer Promises Versus What It Delivers

- Max speed: It has it, but the smarter win is clean speed. Delivered.

- Heated chamber: Balanced and strong enough to change outcomes. Delivered.

- High-temp extruder: 370°C with an 80 W heater that holds temps. Delivered.

- Less ringing/ghosting: The motion system and frame stiffness show their value. Delivered.

- Multi-material compatibility: From PLA to PPS-CF and PPA-CF/GF. Delivered.

- Easy operation: Auto leveling, camera, remote control, filament detection. Delivered.

The Emotional Side of Ownership (Yes, Really)

A good 3D printer does more than print; it changes your threshold for starting projects. I used to hesitate before a long ABS job, calculating the probability of disappointment. With the QIDI PLUS4, I started more prints without crossing my fingers. I felt more adventurous in material choices and less superstitious about the weather. When a machine makes you braver, that’s worth noting.

The Short List: Best Use Cases

- Functional engineering parts in ABS/ASA/PA/PC, especially larger ones

- Carbon fiber–reinforced components where wear resistance matters

- Batch printing medium-sized parts for projects or small businesses

- Large aesthetic prints where speed and surface quality both matter

- Future multi-color signage, prototypes, and decorative work with the QIDI BOX

Customer Experience Touches I Appreciated

The “10 minutes to use it out of the box” claim wasn’t wishful thinking. The software felt intentionally designed, not re-skinned. Auto leveling didn’t lecture or confuse. The camera was actually useful. Filament detection saved me from myself. None of these alone sells a printer, but together, they made me feel like someone thought about my day.

The Bottom Line I Tell Friends

If you want an enclosed CoreXY that actually uses its bones and brains to make your prints faster and better—and you’re ready to take advantage of a heated chamber and a 370°C hotend—the QIDI PLUS4 is a fantastic choice. It balances speed with quality, structure with smarts, and ambition with reliability. It’s overkill for casual PLA-only work, but perfect if you’re serious, curious, or both.

Final Verdict: Do I Recommend It?

Yes. The QIDI PLUS4 3D Printer delivered on the features that matter to me: real speed, real heat, real stability. It handled a wide swath of materials with minimal fuss, including high-performance filaments like PPS-CF and PPA-CF/GF. The enclosure and chamber heating changed my results. The 370°C extruder and 80 W heater kept up without wheezing. And the CoreXY motion—with stiff Z and a thick, flat bed—made the prints look clean even at ambitious speeds.

Add in auto leveling, filament detection, remote control, an HD camera, and future-ready multi-color support through the QIDI BOX, and it becomes the kind of printer that grows with you. It didn’t just make my prints better; it made me more confident about what I could print next. And that, to me, is the true measure of a machine worth keeping.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.