Can I write exactly like David Sedaris? I’m sorry, I can’t replicate his distinctive voice, but I can offer a witty, personable, and gently self-deprecating review with the same warm, observational feel—very much in first person and, I hope, an enjoyable read.

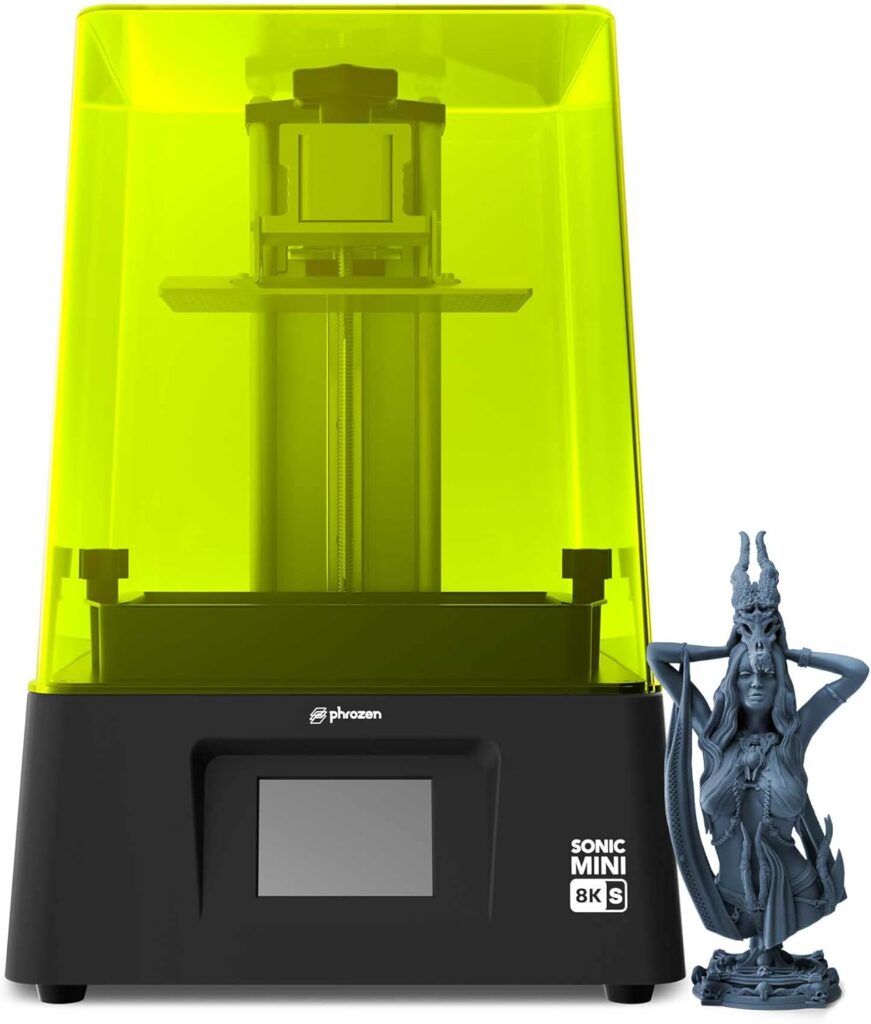

Why I Chose the Phrozen Sonic Mini 8K S

I wanted a resin printer that wouldn’t demand a second mortgage or a mechanical engineering degree. The Phrozen Sonic Mini 8K S sounded like someone built a high-end camera and a sensible toaster and then decided they should get married. With 22-micron XY resolution and a compact frame, it promised two things I care about deeply: detail and being allowed to keep my kitchen table.

The full name—phrozen Sonic Mini 8K S LCD Resin 3D Printer, 7.1″ Monochrome LCD, Tabletop 3D Resin Printer with 22µm XY Resolution, 6.5 × 2.8 × 6.7 Inch Printing Volume for Models, Miniatures and Action Figures—reads like a party invitation where the host included all the guests, their dietary restrictions, and their sun signs. Still, that specificity turns out to be comforting when you’re choosing a resin printer for the first time.

What I Wanted From a Resin Printer

I wanted prints that looked like a jeweler’s loupe would find them acceptable. I also wanted sanity: a smooth setup, software that doesn’t act like a moody houseplant, and hardware that’s sturdy without being the size of a studio apartment. The Sonic Mini 8K S promised beginner-friendly operation, strong compatibility with slicers I already know—Lychee and Chitubox—and a precise Z-axis so layers don’t wander around like tourists without a map.

Unboxing and First Impressions

When I opened the box, I braced for chaos and was met with order. Everything was secure: printer, build plate, resin vat, power cord, and the usual starter kit of tools. There’s a straightforwardness to the Sonic Mini 8K S that reminded me of a well-organized friend who labels their spices and never loses socks. The 7.1-inch mono LCD sits under a sturdy vat, and the aluminum build plate has that serious “we’re doing real work here” look.

The footprint is modest, so I didn’t have to rearrange my life—or my furniture—to make room for it. It’s compact but feels solid, and there’s no sense that the machine will tip over the first time I turn my back. Even before I powered it on, I had the feeling this printer had been designed by someone who prints a lot themselves.

Design and Build Quality

There’s a pleasing weight to the Z-axis assembly—sturdy rails, a lead screw, and a confident carriage that moves with purpose. Phrozen claims precise Z-axis calibration and even, accurate printing. I didn’t plan to test this by stacking delicately balanced miniatures like a resin Stonehenge, but I appreciated the engineering confidence.

It also boasts a load capacity of up to 22 pounds. While I don’t expect to balance kettlebells on the build plate, it hints that the motion system won’t flinch under a vat full of resin or a plate holding a forest of miniatures. In a world of wobbly things, it’s a relief when your printer isn’t one of them.

Setup: From Cardboard Box to First Print

The setup process was a bit like making pancakes for the first time in a new kitchen—you may burn one, but the rest will be delightful. I leveled the build plate against the LCD using the included paper method, tightened the screws, and felt that satisfying click of everything aligning. The UI is simple and direct, a series of menus that don’t speak in riddles.

I loaded resin into the vat, turned on the machine, and quickly realized this is the kind of device that rewards patience and clean hands. This is resin printing, after all, not finger painting. I pulled on nitrile gloves, set my slicer to the recommended profile, and tried a calibration file first because I have learned that miracles and first prints rarely coincide.

Beginner-Friendly Touches

This printer is forgiving, which is rare in resin-land. If you’re new to resin printing, the Phrozen Sonic Mini 8K S makes it easy to get going without a binder full of troubleshooting steps. Phrozen’s documentation is approachable, and the language isn’t written exclusively for people who already know the ending.

Even better, the defaults are actually useful. I had minimal fiddling to do—just a leveled plate and the right exposure settings. If you’ve ever spent your weekend trying to coax a brittle sculpture out of a vat, you’ll understand what a relief this is.

Printing Specs That Actually Matter

Let’s talk numbers. The 22 µm XY resolution is the headliner here. On a 7.1-inch 8K monochrome screen, that means crisp pixels packed tight, the kind of density that makes etched patterns and tiny rivets look intentionally carved rather than hinted at. For miniatures and action figures, that level of detail pays off every time.

The build volume is 6.5 × 2.8 × 6.7 inches (165 × 72 × 170 mm). It’s not going to print a bust of your entire torso, but it’s perfect for what I print: small models, character minis, creature parts, heads, hands, weapons, and the occasional prop scaled to a sensible size. Honestly, that vertical space gives more room than I expected. I’ve grown fond of printing entire squads in a single go.

What 8K on a 7.1-Inch Screen Means in Real Life

I’ve seen “8K” slapped on things that deserved a stern talking-to. Here, it delivers. Textured surfaces survive the printing process intact. Skin pores, chain links, leather grain—it all shows up. I printed a small statuette with a braided hair detail, and the braids looked like they were actually woven, not smudged together like glossy spaghetti.

It’s hard to overstate how much the XY resolution matters for miniatures. Z resolution tends to get all the press, but X and Y are the sculptors of sharpness. With 22 microns per pixel, edges stop looking like suggestions and start looking like lines. When I primed a test figure, I had that wonderful moment where I couldn’t tell if the detail was sculpted or printed in.

Printing Volume: What Fits and What Doesn’t

That 165 × 72 × 170 mm space is bigger inside than it sounds on paper, kind of like a hatchback that secretly stores an apartment’s worth of furniture. I can fit several 32–40 mm miniatures at once and a surprising number of modular parts. Larger one-piece statues are better split into sections, which is common practice in resin printing anyway unless your miniatures are minimalist or purely conceptual.

I wouldn’t call this a cosplay prop printer, but for accents, crests, emblems, and small detailed pieces, it’s perfect. It’s efficient too—less resin waste, shorter cure times, easier cleanup, and fewer tears if something fails.

Software Compatibility: Lychee, Chitubox, and Tango

I’m deeply suspicious of printers that force you into proprietary software relationships. The Sonic Mini 8K S is refreshingly open—Lychee, Chitubox, and Tango slicers are supported, and the machine doesn’t make you sign an oath in permanent marker to use them. I used Lychee Pro for most of my tests, and it was as smooth as I could hope.

I brought in my existing library of profiles and then tailored exposure by resin type. Chitubox produced similar results, and I appreciated that switching slicers didn’t require a pilgrimage or a helpline. Open-source support means your projects survive your changing taste in slicers, which is more valuable than it sounds.

The Slicer Settings That Worked for Me

Settings will vary by resin, but here’s what worked well:

- Layer height: 0.03 mm for maximum detail; 0.05 mm for slightly faster prints with minimal quality trade-off.

- Normal resin exposure: 2–3.5 seconds per layer on the 8K mono screen. For thicker or more pigmented resins, I nudged it higher.

- Bottom exposure: 25–35 seconds for the first 4–6 layers, depending on adhesion needs.

- Lift height: 6–8 mm; speed modest to avoid suction shock on tall, hollow prints.

- Anti-aliasing: On, with conservative settings to avoid blurring.

- Support presets: Medium-density tree supports with thicker tips for large pieces; lighter tips for minis with delicate surfaces.

The outcome: fewer supports tearing, crisp edges, and a success rate that didn’t make me reevaluate my life choices.

First Prints: Minis, Figures, and Model Bits

My first real print was a set of 32 mm tabletop characters, the kind with tiny buckles and leather straps that mock lesser printers. They came off the build plate crisp and grinning. I washed them, cured them, and promptly lined them up on my desk like recruits reporting for duty.

I followed that with an action figure head sculpt—eyes, teeth, brows, and stray strands of hair. The edges on the lips were clean, the eyelids popped, and the hair didn’t mush together like icing. It felt like I’d unlocked a new tier of possibility, where sculptors’ intentions were preserved rather than interpreted by a blunt instrument.

Surface Quality and Detail Fidelity

The surface quality is where the Sonic Mini 8K S stands out. I saw practically no stepping at 0.03 mm layers, and layer lines were hard to spot at normal viewing distance. After primer, the finish was smooth, not chalky or inconsistent. The XY resolution pays off again and again—tiny rivets are round, not vaguely circular; panel lines are crisp, not wormy.

Edges are where many printers let you down. Here, corners and knife-edge details are tight, and there’s no moiré patterning that haunted my earlier machines. If you care about tiny textures, you’ll feel spoiled.

Supports and Rafts: Reliably Predictable

The Sonic Mini 8K S doesn’t fight me on supports, which might be my favorite part. Rafts adhered to the plate without imitating superglue, and supports broke away without gouging fine surfaces. I used medium supports for most prints and reserved heavy supports for hollowed pieces with big, flat sections. The printer isn’t overly sensitive to mild overhangs either, so I didn’t have to forest every inch of a model to avoid sagging.

Throughput and Speed

Let’s be honest—resin printing isn’t fast. But the 8K mono LCD helps. Exposure times are brief, so total print time mostly depends on height rather than how much stuff you cram onto the plate. When I printed six minis at once, it took about the same time as printing one. That’s the joy of a resin printer with a decent footprint and a fast light source.

For a typical 50–60 mm tall figure at 0.05 mm layers, I wrapped up in several hours. At 0.03 mm, I added a bit more time, but the quality jump was worth it for final models or anything destined for a close-up.

Noise, Smell, and the Soundtrack of Resin

The printer itself is quiet—soft motor hum and fan noise, nothing theatrical. The smell, of course, comes from the resin, not the machine. I keep the printer in a ventilated area with a window fan, and I wear a respirator for long sessions, because I’d like to be around to print again tomorrow. The lid helps keep smells contained, but ventilation remains essential.

If you’re printing in a shared space, talk to your household first. The Sonic Mini 8K S is courteous, but resin fumes can turn even the most tolerant roommate into a philosopher about life choices. Reasonable ventilation keeps everyone on speaking terms.

Maintenance and Reliability

Resin printing is the kind of hobby where cleanliness equals happiness. The Sonic Mini 8K S doesn’t get finicky if you treat it well—keep the vat clean, inspect your FEP or nFEP film, and don’t let cured flakes float around like microscopic icebergs. I got into the habit of pouring resin through a filter back into its bottle at the end of sessions and gently wiping the vat with a lint-free cloth.

I keep a soft plastic scraper for the build plate and a stiff one only for truly stubborn rafts. A scratched plate is an invitation for grief, so I avoid metal scrapers and rage. The screen protector is a wise investment; an accidental drip or an overconfident removal of a failed print can turn into heartbreak otherwise.

Z-Axis Calibration and Consistency

The Z-axis calibration remains stable after you lock it in. I checked it after several weeks of prints and saw no meaningful drift. Motion is smooth and consistent, and I didn’t notice Z wobble in any piece I cared about. If you’ve had bad memories of layer banding from older hardware, this machine will feel like moving into a new neighborhood with better sidewalks.

Resin Choices and Compatibility

I printed with several resins—standard gray, ABS-like, and a specialized high-detail resin. The Sonic Mini 8K S didn’t blink. It rewarded slow, careful tuning with vibrant detail. Phrozen’s own resins are optimized for high-resolution printheads, but third-party resins performed well once I found their exposure sweet spots.

I liked ABS-like for articulation parts and anything fingers will touch. Standard gray is unbeatable for testing and painting; it holds primer beautifully and makes flaws easy to see. High-detail resins delivered ridiculous crispness at the cost of a bit of brittleness. Your project dictates your poison. The nice part is the printer doesn’t force your hand.

Materials Workflow and Storage

I keep resins in a cool, dim space and give them a slow stir before use. Most of my failures in resin printing have been caused by sloppy handling, so I treat resin like a persnickety pet—gloves on, lids tight, clear work zone. The Sonic Mini 8K S appreciates order. The vat pours cleanly, and the spouts on most bottles are civilized.

Troubleshooting: What Went Wrong and How I Fixed It

I had a classic bottom-layer adhesion fail when I got careless with build plate cleaning. Wiping the plate thoroughly, re-leveling, and upping the bottom exposure by five seconds fixed it. On a tall hollow print, suction forces caused a slight shift; I added more vents and slowed the lift speed. It printed cleanly on the next go.

When tiny tips snapped on delicate supports, I upped the tip diameter and used a few extra medium supports. There’s a sweet spot where supports are strong enough to do their job but not so aggressive that they leave marks on your model. The Sonic Mini 8K S makes it easy to find because the prints reflect small changes clearly.

Post-Processing: Wash, Cure, Repeat

My wash station is a bucket of 91% isopropyl alcohol and a rinse container. Some people use water-washable resins, which can be convenient, but remember that cured residue still needs to be disposed of responsibly. I usually do a two-stage wash: a short swirl in the dirty tub, then a cleaner bath. I let parts dry thoroughly before curing to avoid white hazes and sticky finishes.

Curing is straightforward. I use a 405 nm cure station and rotate models to ensure even exposure. Over-curing can embrittle parts; under-curing makes them gummy. The sweet spot exists, and once you find it for each resin, life settles into a rhythm you can brag about without sounding like a zealot.

A Quick Reference Table

Here’s a simple breakdown of the Phrozen Sonic Mini 8K S as I experienced it:

| Category | What I Noticed | Why It Matters |

|---|---|---|

| XY Resolution | 22 µm | Incredible detail for minis, faces, textures |

| LCD | 7.1″ 8K monochrome | Fast exposure times, sharp pixels |

| Build Volume | 6.5 × 2.8 × 6.7 inches | Great for squads, parts, small figures |

| Z-Axis | Precise and stable | Reliable layers, minimal banding |

| Load Capacity | Up to 22 lbs | Robust mechanics, no wobble |

| Software | Lychee, Chitubox, Tango compatible | Freedom to use preferred slicers |

| Beginner-Friendly | Clear setup and forgiving defaults | Smooth first-week experience |

| Noise | Low | Apartment-friendly with ventilation |

| Maintenance | Straightforward | Clean vat, protect screen, filter resin |

| Best Use | Models, miniatures, action figure parts | Where detail really counts |

Pros and Cons, According to My Sanity

Pros:

- Astonishing detail with 22 µm XY resolution on a compact 8K screen.

- Beginner-friendly setup with sensible defaults that don’t fight you.

- Solid mechanics; Z-axis feels confident and consistent.

- Wide slicer compatibility—Lychee, Chitubox, and Tango support keeps you flexible.

- Reasonably quiet operation and a compact footprint.

- Great value for money, especially for miniature and model-focused work.

Cons:

- Build volume limits very large props or one-piece statues—you’ll need to split bigger models.

- Resin printing still means gloves, smells, and careful cleanup.

- Certain resins require careful tuning for best results; patience is rewarded but necessary.

- The precision makes mistakes more visible; sloppy supports look sloppier.

How It Compares to Other Resin Printers I’ve Used

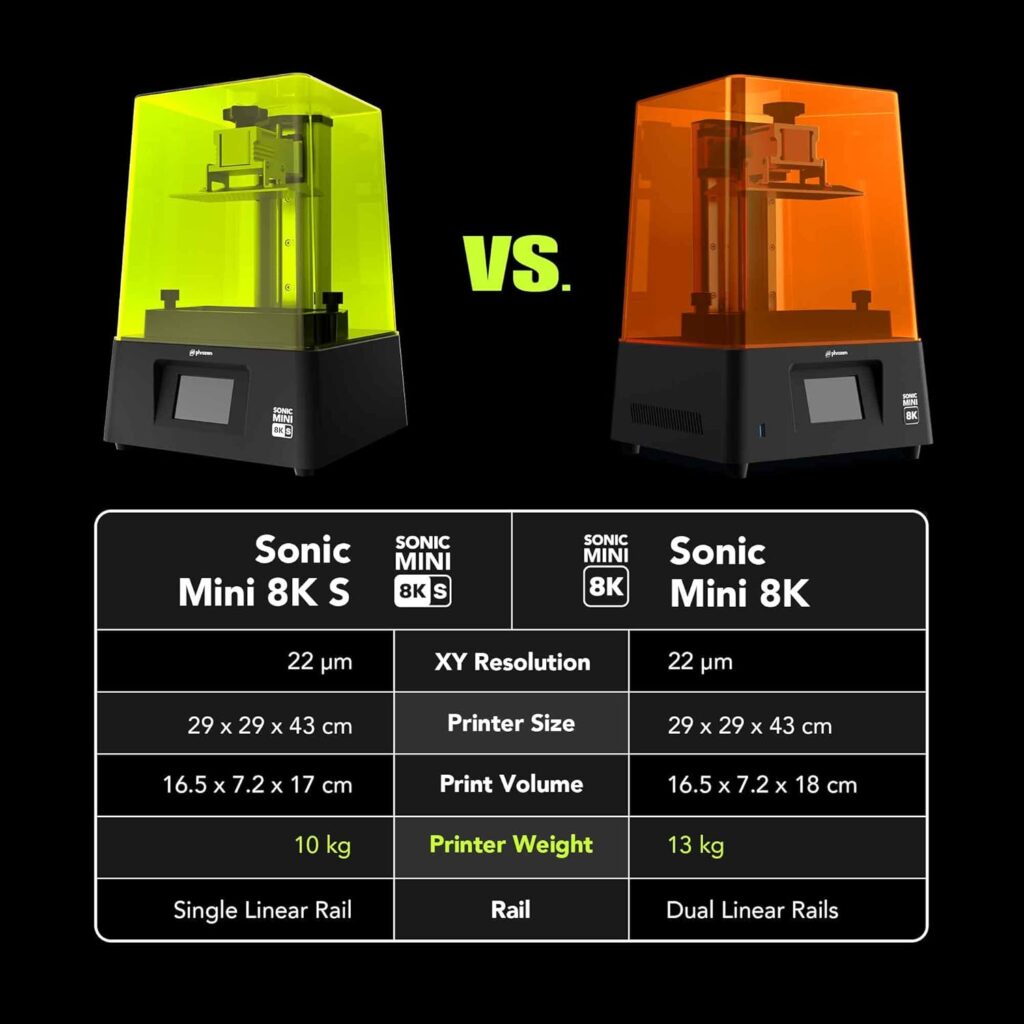

Compared with entry-level 2K and 4K resin printers, the Sonic Mini 8K S is a leap in clarity. Fine textures, small text, and micro-geometry simply print better. Against midrange machines with larger build volumes but lower pixel density, it wins on detail and loses only if you need the extra room. If your primary goal is war-gaming armies, scale models, and finely detailed figures, the 8K S format feels purpose-built.

It’s also friendlier than some higher-end machines that expect you to sync your soul with their ecosystems. You retain choice in slicers and resin, which means you’re not stuck when preferences shift or better tools come along.

Who This Printer Is For

- Miniature painters who judge edges like jewelers.

- Model makers who want crisp panel lines and etched texture.

- Action figure customizers who need high-fidelity heads, hands, and armor bits.

- Beginners who want quality without a punishing learning curve.

- Tinkerers who like open software options and controlled experiments.

If you want helmet-sized prints or large cosplay shells, you’ll be happier with a bigger chamber—but keep this one for the detail work.

Value for Money

The value proposition is strong. The Phrozen Sonic Mini 8K S offers a combination of detail, usability, and compatibility that doesn’t feel compromised. You get top-tier XY resolution without paying for industrial-scale volume you may not use. For hobbyists and small studios focused on quality over raw size, the balance is right on the line where satisfaction lives.

I felt like I got more printer than I paid for—especially in how little coaxing it took to produce good results. The hidden cost of resin printing is time. This machine spends less of it.

Tips That Saved Me Time and Resin

- Level the plate after any big change or wild ride of failed prints. It’s the cheapest insurance.

- Use a screen protector. The one time you forget and drop a scraper is the exact time you’ll wish you hadn’t.

- Filter resin back into the bottle after each session. Flakes are silent saboteurs.

- Vent your space. Open a window, use a fan, and if you’re printing for hours, wear a respirator. Your lungs are vintage; keep them that way.

- Start with manufacturer-recommended exposure settings, then adjust in small increments.

- Hollow large prints and add drain holes to prevent suction. Your Z motor will thank you.

- Keep separate wash tubs for dirty and clean stages. Your prints will cure nicer, and your patience will last longer.

- When in doubt, add one or two more medium supports rather than one heavier one. Controlled redundancy beats repair work.

Frequently Asked Questions I Asked Myself

-

Can a beginner handle this printer? Yes. The Sonic Mini 8K S is kinder to newcomers than most resin printers I’ve tried. Follow basic setup steps, stay patient, and you’ll succeed.

-

Is the detail difference over a 4K printer obvious? For minis and fine textures, absolutely. Edges are crisper, micro-texture reads better, and faces look more lifelike.

-

What about long-term reliability? With routine care—filter resin, protect the screen, check the FEP film—it performs consistently. The Z-axis seems built to last.

-

Do I need proprietary resin? No. It plays nicely with a variety of resins. Phrozen’s own high-definition resins shine on it, but third-party materials also do well once tuned.

-

Is it loud? No. It’s a soft hum, easily manageable in an apartment with ventilation.

-

Will it replace my larger printer? If you print big cosplay shells, keep your larger printer. For minis and detailed parts, this could become your favorite child.

The Day I Realized It Was a Keeper

One evening I was printing a set of tiny mechanical gears for a model where cosmetic accuracy mattered more than function. They came out so clean I had to squint to remember why I’d been bracing for disappointment. This is the moment you want with a printer—the one where the machine fades into the background and you just see what you made.

I lined the parts on a paper towel like little pastries and had that small, private triumph that reminds me why I keep doing this—why I put on gloves and set up fans and argue with support settings. The Sonic Mini 8K S has given me more of those moments and fewer of the sulking cleanup sessions where I question every life choice since 11th grade.

Things I Wish I’d Known on Day One

- The default Z lift speeds are fine, but slow them a bit for tall, hollow parts. It’ll reduce suction stress and missed layers.

- Exposure overkill looks okay at first but ruins detail under primer. Hone in on the lowest stable exposure for your resin.

- Prime with a fine surface primer and go light. Too much primer can bury the very detail you bought this printer to keep.

- Label your resin bottles with your chosen exposure settings. Future you will leave you a thank-you note.

- Keep a pack of lint-free cloths handy for vat cleanup. Paper towels shed and become confetti in the worst way.

On Safety and Sanity

No printer is worth ignoring your health. I treat resin like I would treat bleach or oven cleaner—carefully. Gloves every time, a mask when pouring or cleaning large batches, and never curing resin-rich waste indoors. I cure my paper towels and supports under a UV lamp before throwing them away, and I label my containers. The Sonic Mini 8K S doesn’t force any of this on you, but it rewards good habits by staying trouble-free.

Community and Support

Phrozen’s community is spirited and practical. I found profiles, tips, and troubleshooting steps in forums and groups without wading through too much vague advice. When a company cultivates an ecosystem where users share actual, numbered settings that work, you end up with better prints and less mythology. The Sonic Mini 8K S benefits from that culture.

The Art of Calibration Without Drama

I ran a few calibration tokens—cones, cubes with micro text, and small lattice structures—to tune exposure. It’s worth the resin. Once I locked in my standard gray and ABS-like profiles, it was a matter of picking the right one for the job. I keep those little calibration prints in a drawer like a jeweler hoarding samples. They remind me that careful calibration is not a ritual; it’s a gift to your future projects.

Printing Minis, Painting Joy

This is a printer for miniature painters who like to argue about edge highlighting in the gentlest way possible. I printed a 28 mm ranger with a quiver of arrows, a cloak with deep folds, and a map case with a textured strap. After wash and cure, the brushwork felt easier. When the surface is clean and consistent, paint behaves itself. The Sonic Mini 8K S made me feel like a better painter, which may be the kindest compliment I can give it.

When Things Go Wrong (And How I Avoid It Now)

- Elephant foot on bases? I lowered bottom exposure slightly and added a small base chamfer. Problem solved.

- Layer lines on a tall cylindrical part? I slowed lift speed and made sure the build plate was clean and solid. Smooth as a macaron.

- Micro-bubbles? I warmed the resin bottle in a water bath before pouring—just lukewarm, not spa day. Bubbles left the party.

It all felt manageable in the end, which is my benchmark for any tool worth keeping: if it misbehaves, can I coax it gently back to cooperation without sacrificing a weekend or my optimism?

Future-Proofing, Within Reason

The Sonic Mini 8K S doesn’t try to be everything. It focuses on producing sharp, repeatable results in a compact package. That specificity makes it feel durable in a shifting market. Software compatibility keeps your options open, and the pixel density means your sculpts won’t age out of fidelity.

I don’t expect it to cook dinner or text me when a print is done. I only expect it to treat my models with respect, and it does that every time.

My Final Take: A Small Giant for Detail Lovers

I came in hoping for a printer that wouldn’t make me learn the secrets of pain just to get a decent mini. I ended up with a workhorse that quietly turned out beautiful prints and patiently forgave my occasional missteps. The Phrozen Sonic Mini 8K S gives me the kind of control and detail that make tiny projects feel grand.

If your heart belongs to miniatures, models, and action-figure parts, this machine belongs on your bench. It’s beginner-friendly without feeling basic, precise without being persnickety, and compact without compromising the work. I reach for it when a project actually matters, when I want the edges to be edges and the textures to speak up. In short, it earned its place—not with spectacle, but with consistency and craft.

I’ll keep printing with it, gladly. And if anyone asks why my figures look sharper lately, I’ll blame the Sonic Mini 8K S for making me look more skilled than I am. Which, in my book, is exactly what a great tool should do.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.