Have you ever stopped to think about the things we can’t see without a microscope? I know that sounds a bit peculiar—pondering over the invisible. But what if I told you that we’re on the cusp of crafting with such precision that these tiny wonders are becoming not just an academic amusement, but a commercial reality? Yes, I’m talking about the fascinating world of nano-scale 3D printing. The journey of bringing microscopic manufacturing into a commercially viable market is like something out of a sci-fi novel, but it’s rapidly becoming a part of our tangible reality. Let’s wander through this miniature jungle together and discover what it all means.

Understanding Nano-Scale 3D Printing

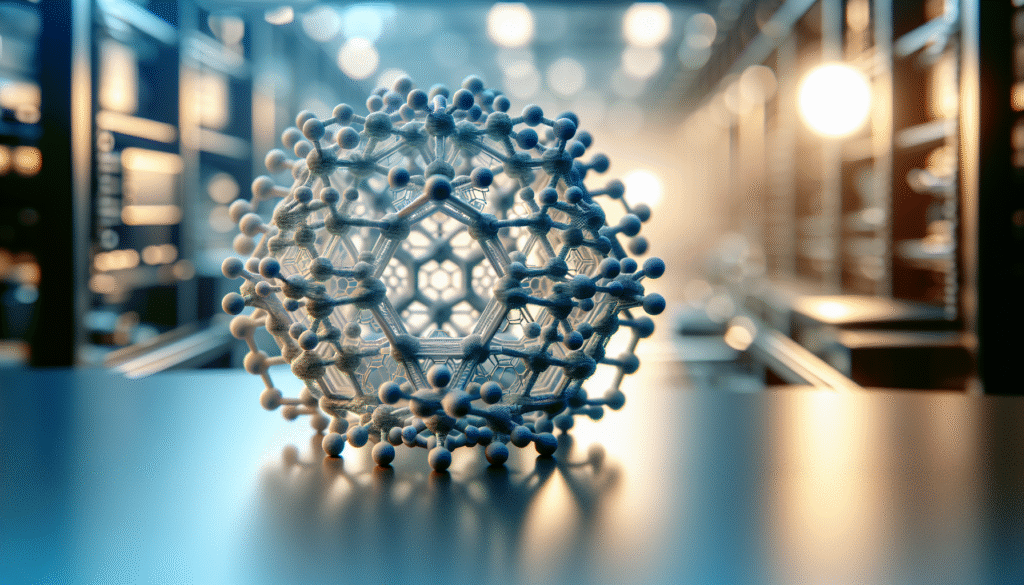

In the grand tapestry of technology, nano-scale 3D printing stands out as a prodigious achievement. But what exactly does this term mean? Picture this: we’re talking about creating objects at a scale so small, you’d need a powerful microscope just to admire the handiwork. Imagine how intricate and delicate these objects must be—they’re crafted at a scale where dimensions are measured in nanometers. For perspective, a single nanometer is one-billionth of a meter. It’s like trying to appreciate the fine details of a grain of sand in a desert of technological possibilities.

The Science Behind It

At its core, nano-scale 3D printing is about manipulating matter at an atomic or molecular level. The techniques employed in this realm of manufacturing are often bewildering yet tantalizing. From processes like two-photon polymerization to electron beam lithography, the science gets fascinatingly intricate. Two-photon polymerization, for example, employs lasers to solidify a resin in very specific points, piecing together a 3D structure with astonishing precision.

How Does It Differ from Regular 3D Printing?

While we might initially lump all 3D printing into the same category, nano-scale fabrications play in a league of their own. For starters, regular 3D printing—which itself revolutionized manufacturing—operates at a much larger scale compared to its nano counterpart. We’re talking about the difference between printing a toy model and printing the mechanics for a bionic ear.

| Feature | Nano-Scale 3D Printing | Regular 3D Printing |

|---|---|---|

| Scale | Nanometers (1-100 nm) | Millimeters and above |

| Precision | Ultra-high, atomic level | Moderate, detail size limited |

| Materials | Specialized resins, metals | Plastic, metals, resins |

| Cost | Generally higher | Variable, often lower |

| Speed | Slower due to precision | Faster in comparison |

The Applications of Nano-Scale 3D Printing

The applications of this technology stretch as vast as the imagination allows. Let’s discuss some of the groundbreaking uses that are not just theoretical, but actively in development or already in the marketplace.

In Medicine: A New Frontier

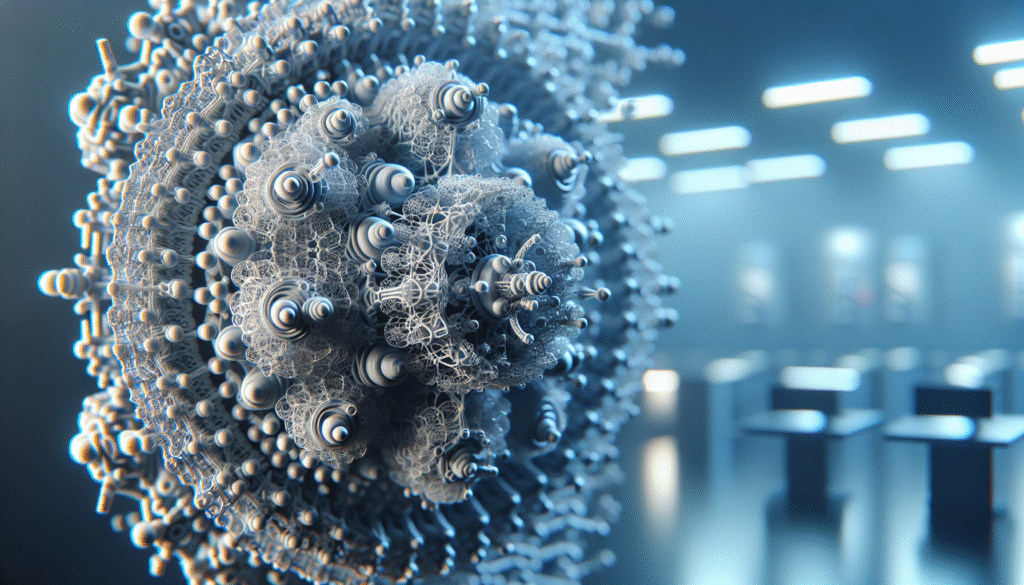

Have you ever thought about what goes inside a drug or how medical instruments are produced with such intricacy? Nano-scale 3D printing is revolutionizing medical diagnostics and treatment through innovations like nanoscale scaffolding for cell growth, which is a major leap forward in tissue engineering and regenerative medicine. Imagine creating a scaffold from which organs could grow, essentially reducing the need for organ donors. It’s like biology fiction dreaming, but less fiction and more biology.

Electronics: Shrinking the Circuit

In electronics, the ability to print at such small scales opens up the possibility for producing smaller, more efficient circuits. As our demand for miniaturization grows—putting more power into our mobile devices without increasing their size—this technology is crucial. What used to take up a room can now fit into your pocket, and soon, perhaps, even smaller than that.

In Research: Enabling New Explorations

Research institutions are leveraging the power of nano-scale 3D printing to conduct previously unimaginable experiments. Whether it’s creating complex models to study microscopic organisms or simulating cellular environments, the possibilities for scientific advancement are endless.

The Challenges and Limitations

Of course, no cutting-edge technology comes without its set of hurdles. The marvel of nano-scale manufacturing is not without significant challenges. These include costs, material limitations, and the sheer complexity of the technology.

Cost Implications

Producing at such a fine scale requires expensive equipment and materials, which can make commercial viability a daunting endeavor. The cost of purchase, maintenance, and operation can be prohibitively expensive, although prices may come down as the technology matures and becomes more mainstream.

Material Challenges

The range of materials that can be printed at the nano-scale is currently limited. The advancement of material science is crucial in broadening the spectrum of possibilities and applications. Developing new polymers and resins that can withstand the rigors of such precise manufacturing is an ongoing field of research.

Technical Complexity

The precision required for nano-scale printing is immense. As you can imagine, the machinery and techniques employed must be precise to a fault, which in itself presents a significant barrier. The complexity of programming and engineering these devices can lead to high innovation thresholds.

Future Prospects

Despite these challenges, the outlook for nano-scale 3D printing is incredibly optimistic. It’s only natural to wonder where the potential pathways might lead us.

Towards Mainstream Adoption

As we make strides in cost reduction and material development, I foresee this technology permeating more industries. Like I mentioned earlier, just as computers transformed from room-sized behemoths to the smartphones in our hands, nano-scale printing technology will become more ubiquitous, finding its place in everyday applications.

Continued Innovation

Innovation breeds further innovation. With more companies and researchers diving into this field, we are bound to see advancements and unexpected breakthroughs. From healthcare to fashion, the possibilities continue to expand as creative minds explore new uses for this phenomenal technology.

Environmental Impact

Let’s take a moment to ponder the environment. Nano-scale 3D printing has the potential to significantly reduce material waste compared to traditional manufacturing processes. It’s like the technology offers us a path to a future with a smaller ecological footprint—an appealing thought as we become more mindful of our environmental impact.

Conclusion

Nano-scale 3D printing is as much a testament to human ingenuity as it is a revelation in manufacturing technology. As microscopic manufacturing edges closer to commercial viability, each step forward feels like a page-turner in the ongoing story of innovation. We’re standing at the brink of a new industrial revolution, one that may indeed be too small to see with the naked eye but has the potential to create ripples across the globe. I can’t help but think of all the journeys waiting to unfold as we traverse the nuanced landscapes of this tiny universe. Keep your microscopes handy; the adventure is just beginning.