Have you ever wondered how robots are changing the game in the finishing touches of 3D printing? It might sound like something out of a sci-fi movie, but this is very much the current reality in the world of modern manufacturing. With a surge in the use of 3D printing in industries ranging from healthcare to aerospace, the demand for exceptional final products has never been higher. That’s where robotic post-processing steps in, promising not just precision and time efficiency, but also significant improvements in the overall quality of 3D printed objects.

The Basics of 3D Printing and Post-Processing

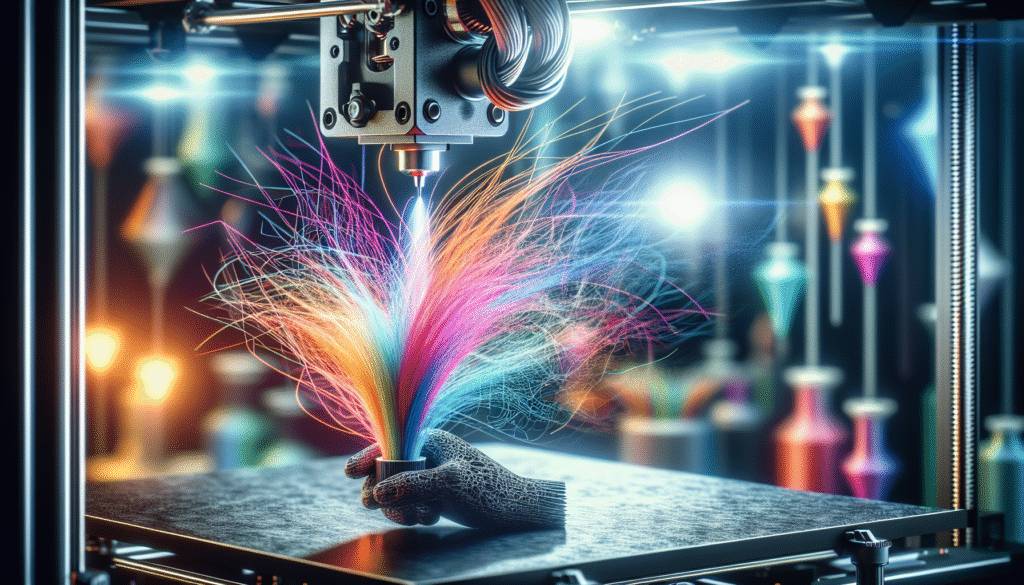

3D printing, also known as additive manufacturing, is an incredible process where objects are created layer by layer from a digital file. The technology is versatile, allowing for the creation of complex geometries that would be impossible or very expensive to make using traditional manufacturing techniques. However, the 3D printed parts straight out of the printer aren’t always perfect. They often require additional work to meet the desired finish, which is what we call post-processing.

Post-processing involves several steps: support removal, sanding, polishing, painting, and coating, among others. All these stages are aimed at improving functionality, performance, or aesthetic value. While necessary, these steps can be labor-intensive and time-consuming when done manually. Thus, the introduction of robots into this arena seems like a match made in technological heaven.

What is Robotic Post-Processing?

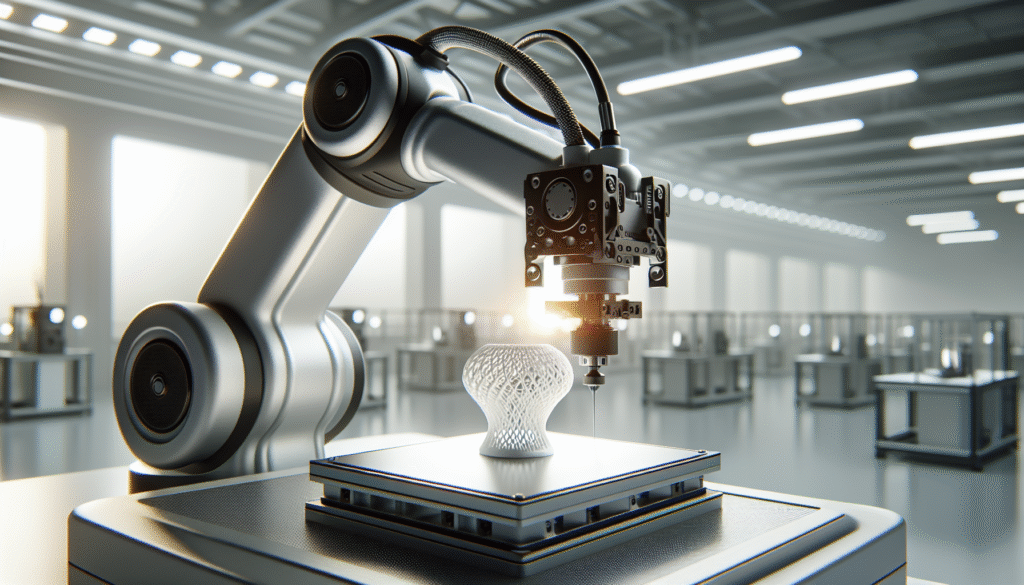

Robotic post-processing refers to the involvement of robotic arms and systems equipped with various tools to carry out post-processing tasks on 3D printed objects. These robots don’t just take over repetitive tasks; they elevate the quality of work by enhancing consistency, precision, and speed. Think of them as highly skilled craftsmen who never get tired or make errors from fatigue.

Advantages of Robotic Involvement

Precision and Quality Consistency

Robots are inherently precise. They can be programmed to follow exact paths and apply equal pressure across multiple parts, ensuring the quality of finish is consistent—something that is quite challenging to achieve manually. This consistency translates to a more reliable product quality, which is crucial for industries where precision is non-negotiable.

Time Efficiency

Time is money, or so the adage goes, and nowhere is this more applicable than in manufacturing. While human workers need breaks and rest, robots can operate around the clock. Their ability to work continuously without drops in performance ensures faster turnaround times, allowing businesses to meet tight deadlines and market demands more comfortably.

Cost-Efficiency in the Long Run

Although the initial expense of integrating robotic systems can be significant, the reduction in labor costs, minimized material wastage, and increased productivity make them a cost-effective solution in the long run. These systems also reduce the likelihood of human error, which can be costly in terms of rework and wasted materials.

Automation in Various Post-Processing Steps

For those not familiar, the post-processing of 3D printed items can be an intricate dance. Yet here we are, welcoming robots to join us as partners. Each dance step is a different aspect of post-processing, and here are some of the most common applications where robots are particularly helpful:

Support Removal

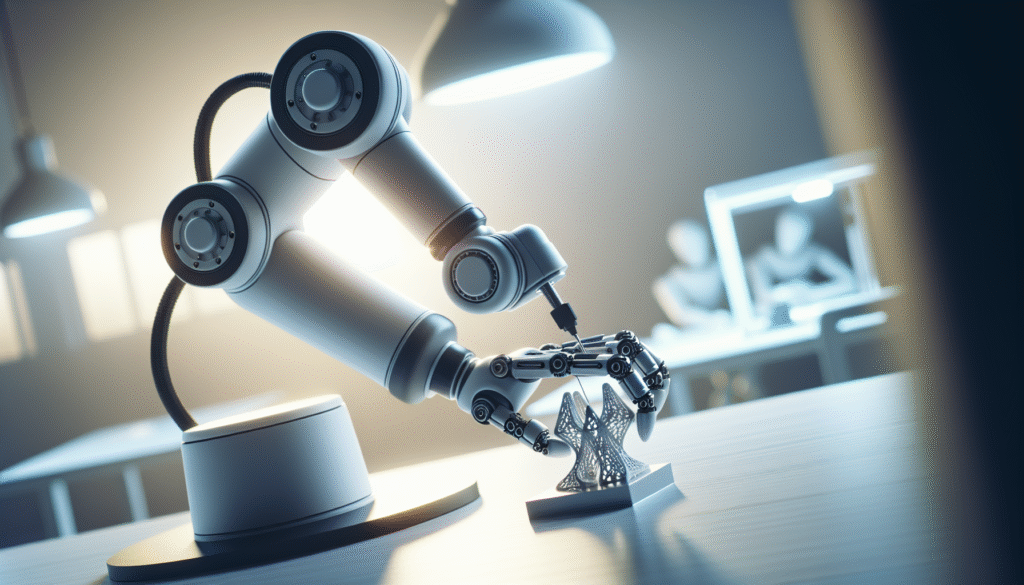

During printing, temporary structures are often used to support overhanging parts. These need to be meticulously removed post-printing. Robots can perform this delicate task with great precision, minimizing the risk of damaging the actual product.

Sanding and Smoothing

Achieving a smooth surface often requires sanding, a tedious job when done manually. Robots equipped with sanding tools can perform this task rapidly and consistently, yielding surfaces ready for further polishing or painting.

Finishing and Coating

Whether it’s painting, applying a protective layer, or other finishings, robots can ensure an even and precise application. This capability can greatly enhance the aesthetic appeal and protective quality of the final product.

Future Trends in Robotic Post-Processing

The intersection of robotics and 3D printing is already proving to be a robust collaboration. Let’s dust off our crystal ball and take a peek at what we might expect in the years to come.

Intelligent Robotics

As artificial intelligence continues to evolve, it’s anticipated that robots will become more autonomous and adaptive. Future robots might be able to identify flaws in real-time and autonomously correct them, further enhancing the stability of product quality.

Integration with Advanced Materials

With advances in materials that allow for more complex and durable prints, robots may also evolve to handle intricate designs and novel materials. This potential opens up even more possibilities for industries that rely on custom and precise manufacturing.

Sustainable Practices

There is a growing demand for sustainability in manufacturing. Robotic systems can contribute significantly by optimizing processes to reduce waste. They could also be involved in recycling or repurposing processes, making it easier to break down parts and reuse materials.

Challenges to Consider

Of course, like all fairy tales, there are obstacles that must be overcome for a happy ending.

High Initial Investment

Implementing robotic systems involves a hefty investment in both hardware and software. For small firms, this might seem prohibitive, despite the promise of long-term savings.

Technical Expertise

Deploying and maintaining these systems requires specialized skills. Hence, companies need to either train existing staff or hire new talent, which can add to the cost and complexity of the transition.

Customization Limitations

Currently, robotic systems are often built for specific tasks and do not yet match human flexibility and adaptability. Customizing solutions for unique projects might still be dependent on manual labor.

Comparing Manual vs. Robotic Post-Processing

It might be useful to compare both approaches using the table below to understand how automation stacks up against traditional methods in post-processing.

| Feature | Manual Post-Processing | Robotic Post-Processing |

|---|---|---|

| Precision | Variable, skill-dependent | High, consistent |

| Speed | Moderate | Fast, uninterrupted |

| Quality Consistency | Inconsistent, variable | Highly consistent |

| Initial Cost | Low hardware costs, high labor costs | High hardware cost, but labor saving in the long run |

| Flexibility | High | Task-specific |

| Labor Requirements | High | Low, requires oversight |

| Error Rate | Higher, skill-dependent | Lower due to precision programming |

Closing Thoughts

So, what’s the final word on robots taking over 3D post-processing duties? Although the journey of integrating robots into post-processing is still unfolding, it’s hard not to be impressed by the improvements they bring. Their precision, speed, and cost-effectiveness provide a compelling case for businesses considering the switch.

However, this is more a partnership than a takeover. There’s still room for human ingenuity in setting up, supervising, and complementing robotic systems, ensuring they work to their full potential. With advancements on the horizon, it seems clear that robots will have a bigger role going forward, opening new doors we probably haven’t even considered yet.

Whether you’re a tech enthusiast, a business owner, or just someone interested in the wonders of modern technology, it’s an intriguing journey to follow, and perhaps, be a part of. Automating post-processing in 3D printing exemplifies how machinery doesn’t replace us but rather enhances what we’re capable of, allowing human creativity to reach new heights.