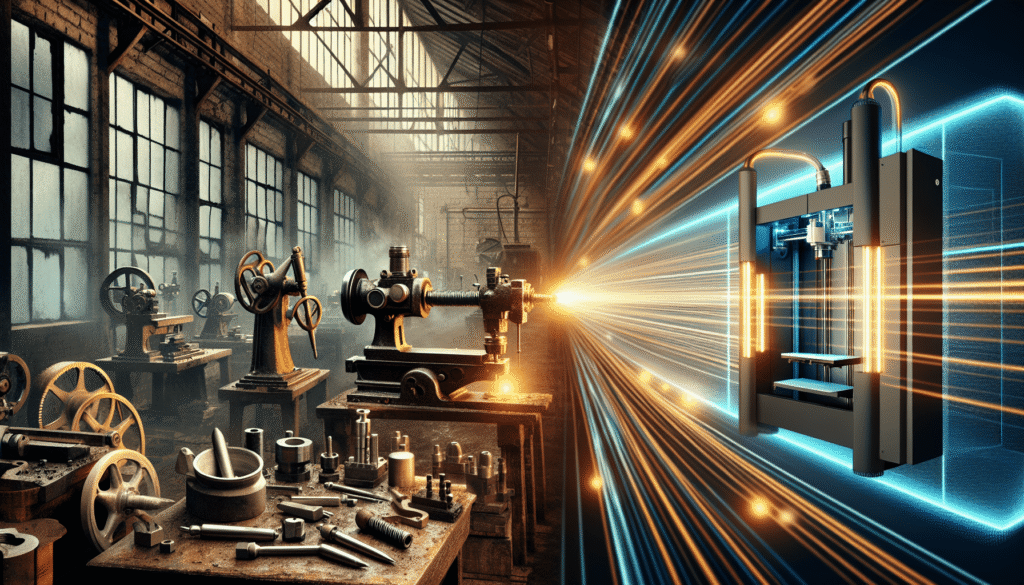

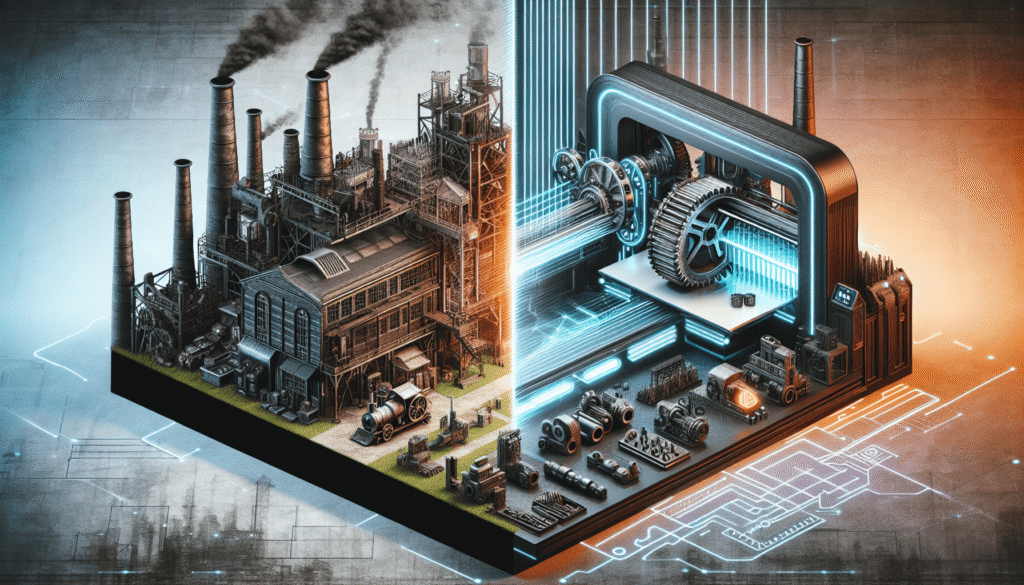

Have you ever wondered what would happen if we combined the age-old art of manufacturing with the flashy, new-fangled innovation of 3D printing? Imagine a world where the precision and reliability of traditional methods meet the flexibility and efficiency of modern technology. Possible, you say? Indeed, thanks to the advancements in hybrid manufacturing systems.

What is Hybrid Manufacturing?

Hybrid manufacturing is a fascinating concept, merging the legacy of traditional fabrication methods with the innovative prowess of 3D printing. This blend of techniques provides a gamut of possibilities that neither method could achieve on its own. While traditional manufacturing excels in volume production and precise cutting, 3D printing shines in creating intricate designs and rapid prototyping. The symbiotic relationship between the two results in a manufacturing process that offers both quality and creativity.

Where Did Hybrid Manufacturing Come From?

Hybrid manufacturing didn’t spring from a single eureka moment but instead evolved as manufacturers experimented with ways to optimize production. The need for more efficient processes coupled with the capabilities of 3D printing technologies led to a natural fusion with traditional methods. This evolution reflects our collective drive to produce better products more efficiently, satisfying both market demands and sustainability goals.

The Importance of Hybrid Manufacturing

Why should we care about hybrid manufacturing? It’s because it represents a new frontier in production efficiency and capability. This method increases design flexibility, reduces lead times, lowers production costs, and can enhance the quality of finished products. By integrating two diverse production methods, hybrid systems offer a strategic advantage to manufacturers willing to innovate, paving the way for more sustainable, versatile, and responsive manufacturing processes.

Exploring the Components

To appreciate hybrid manufacturing fully, let’s break down its core components: Traditional Manufacturing and 3D Printing, along with how they work together in harmony.

Components of Traditional Manufacturing

Traditional manufacturing methods include processes such as machining, casting, and forging. These techniques have been honed over decades, if not centuries, to offer reliable and precise manufacturing outcomes.

- Machining: This involves removing material from a workpiece to form a desired shape, typically through processes like turning, milling, or drilling.

- Casting: Materials are melted and poured into a mold where they solidify into shapes.

- Forging: Involves shaping metal using compressive force, often delivering high-strength components.

What’s remarkable about traditional manufacturing is its ability to produce high volumes of products with consistent quality. But it does have limitations, particularly when it comes to creating complex geometries or handling low production runs efficiently.

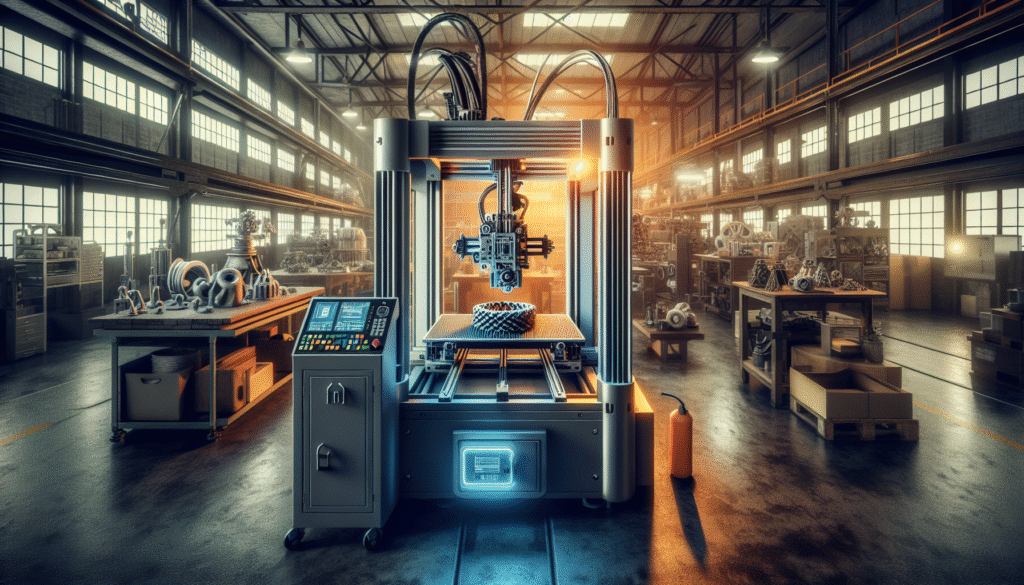

Components of 3D Printing

In contrast, 3D Printing, or additive manufacturing, works by layering material to build objects from the ground up. It’s like printing a document, but in three dimensions!

- Material Extrusion: A popular technique where plastic filament is heated and extruded through a nozzle to form an object.

- Vat Photopolymerization: Uses light to solidify liquid resin into hardened layers.

- Powder Bed Fusion: A laser or other heat source fuses powdered material layer by layer.

3D printing thrives on producing intricate designs and prototypes quickly without the need for complex tooling. However, it’s not yet adept at mass production or producing ultra-durable materials akin to those created through forging or casting.

Synergy in Action: Hybrid Manufacturing

Now, picture these two methods shaking hands. The crux of hybrid manufacturing lies in strategically utilizing the strengths of both traditional methods and 3D printing.

Combining Forces

Hybrid systems combine subtractive methods like machining with additive techniques, allowing for the creation of complex, customized parts that are also precise and durable. For instance, a part can be traditionally manufactured for structural integrity and then augmented with a 3D printed layer for complex aesthetics or specialized function without redesigning the entire piece.

Table: Comparative Advantages

| Feature | Traditional Manufacturing | 3D Printing | Hybrid Manufacturing |

|---|---|---|---|

| Volume Production | Excellent | Limited | Improved |

| Design Complexity | Limited | High | Optimized |

| Material Properties | High Mechanical Strength | Variable | Customizable |

| Lead Time | Long | Short | Balances speed and precision |

| Cost Efficiency | High for large batches | High for small batches and custom designs | Cost-effective throughout lifecycle |

| Customization | Limited | High | Enhanced |

Benefits of Hybrid Manufacturing

-

Versatility and Customization: Offering the best of both worlds, hybrid manufacturing allows for significant customization without compromising structural integrity.

-

Cost Efficiency: By strategically combining production processes, manufacturers can optimize costs across different production stages, minimizing waste and maximizing resource utilization.

-

Time-Saving: Hybrid systems reduce lead times by allowing some parts to be 3D printed rapidly, while traditional methods handle more routine, high-volume production tasks.

Challenges in Hybrid Systems

Of course, melding these two distinct processes isn’t without its challenges. For one, it requires a steep investment in both technology and training. Integrating 3D printing into traditional production lines can be tricky, necessitating substantial workflow alterations. Moreover, manufacturers may face challenges in material compatibility, as the materials suited for traditional manufacturing might not always match those used in 3D printing.

Real-World Applications

Let’s look at where this hybrid technology is being applied today.

Automotive Industry

In the automotive sector, hybrid manufacturing is used to create complex engine components that require the precision of traditional methods, enhanced by the unique geometric capabilities of 3D printing.

Aerospace

In aerospace, hybrid manufacturing is employed for producing lightweight and robust components, reducing material waste and achieving intricate designs not possible solely with traditional methods.

Medical Devices

The medical field benefits from hybrid systems through the creation of customized implants and prosthetics. These products require meticulous accuracy and personalization, something hybrid manufacturing systems can provide adeptly.

Jewelry and Fashion

Jewelry and fashion industries leverage the artistic potential of hybrid manufacturing to create intricate designs that are both cost-effective and unique, bringing haute couture into the realm of digital craftsmanship.

The Future of Hybrid Manufacturing

The landscape of manufacturing is continually evolving, and hybrid systems are right at the vanguard of this change. As technology advances, we can expect even tighter integration between traditional processes and 3D printing, fueled by improvements in AI, robotics, and materials science.

Concluding Thoughts

Hybrid manufacturing represents the very essence of human ingenuity—the drive to combine what we know best with what’s just beyond the horizon. The fusion of old and new technology brings efficiency, creativity, and capability to unprecedented heights. While challenges exist, they are but stepping stones toward more dynamic, responsive, and sustainable manufacturing practices. So next time you glimpse a complex machine part or a sleek consumer product, consider the possibility that it might just be a product of this fascinating hybridization of methods.