Have you ever wondered how traditional manufacturing techniques can coexist with the innovative world of 3D printing? It’s a harmonious blend that has the potential to revolutionize the world of production. I often find myself marveling at how these two seemingly contrasting methodologies can come together to form something greater than the sum of their parts. Today, I want to take you on a journey through the fascinating world of hybrid manufacturing systems, where we’ll uncover how 3D printing is being combined with age-old manufacturing methods to create something truly extraordinary.

Understanding Hybrid Manufacturing Systems

Hybrid manufacturing systems, as the name suggests, are all about blending the new with the old. It’s like inviting your eccentric great-aunt to a modern art exhibit. It might seem like an odd combination at first, but when everything aligns, it becomes a masterpiece of collaboration. This combination leverages the best of both worlds—utilizing the precision and innovation of 3D printing alongside the reliability and expertise embedded in traditional manufacturing methods.

Why Hybrid Manufacturing?

I often ask myself why choose one when you could have the best of both? Hybrid manufacturing systems capitalize on the unique strengths of different production methods, yielding benefits that a single method might lack. By merging techniques, it’s possible to reduce production time, decrease material wastage, and significantly lower costs. It’s a bit like having your cake and eating it too, but in a responsible and economically efficient manner.

The Elements of Traditional Manufacturing

Let’s rewind a bit and dive into traditional manufacturing—think of it as putting on your favorite vintage record. It’s reliable, tested over decades, and it resonates with a certain nostalgic charm. Traditional manufacturing includes machining, casting, molding, and other established processes.

Traditional Manufacturing: The Tried and True

Machining, for example, involves removing material from a workpiece to shape it into the desired form. Casting, on the other hand, pours liquid material into a mold where it solidifies. These methods have stood the test of time and offer precision, strength, and durability. Yet, like an old pocket watch, they might lack the cutting-edge complexity that modern designs sometimes require.

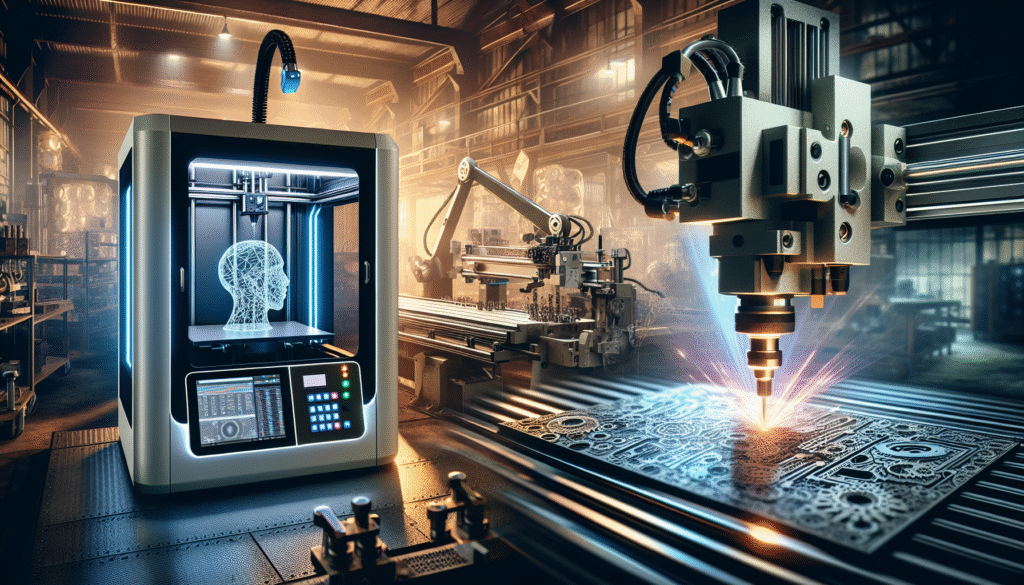

The Innovation of 3D Printing

Ah, 3D printing—a spectacle of modern innovation that’s as exciting as unboxing the latest gadget. It’s a process that allows for the creation of three-dimensional objects through successive layering of materials. It’s flexible, adaptable, and is redefining possibilities across multiple industries.

3D Printing: A New Frontier

In the realm of 3D printing, complex geometries are a playground as opposed to a headache. Where traditional methods might struggle or incur significant costs to produce intricate shapes, 3D printing relishes in the challenge. From prototypes to end-use products, 3D printing efficiently handles variability in design with ease.

Fusion of Techniques

By now you might be wondering, how do these methods work in unison? Well, hybrid manufacturing is like a layered cake—each layer contributing to the overall flavor, enhancing the experience. This fusion is achieved by strategically employing 3D printing for parts of the product that benefit from its unique capabilities, while using traditional methods for the components best suited to those techniques.

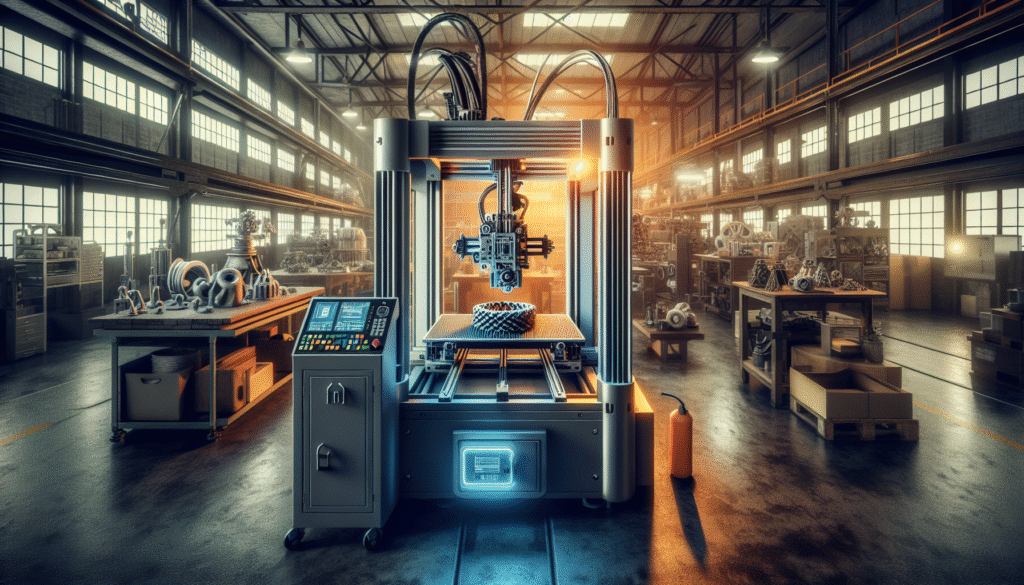

Breaking Down the Combination

Let’s break it down:

- Complex Parts: Utilize 3D printing for components that require complex geometries or customized features.

- Structural Integrity: Rely on traditional techniques like casting or machining for parts where material strength and durability are crucial.

- Volume Production: Traditional methods shine in mass production scenarios due to their scalability.

By combining them, each part of the product benefits from the method best suited for its requirements. Think of it as making a cocktail—selecting ingredients that complement each other to create a balanced and flavorful drink.

Applications in Various Industries

Hybrid manufacturing systems aren’t restricted to just one field; their influence spreads across multiple industries like a pioneering recipe. From aerospace to medical devices, this approach is transforming the way products are designed and produced.

Aerospace

In the aerospace industry, where precision is paramount, hybrid manufacturing allows for the creation of components that are not only lightweight but also incredibly strong. Imagine crafting a balsa wood model of an airplane and giving it the durability and robustness required to conquer the skies.

Medical Devices

Medical devices benefit tremendously from hybrid manufacturing too. Custom prosthetics, for example, can be made with intricate and personalized designs using 3D printing, while utilizing traditional methods to ensure robustness and compliance with stringent safety standards.

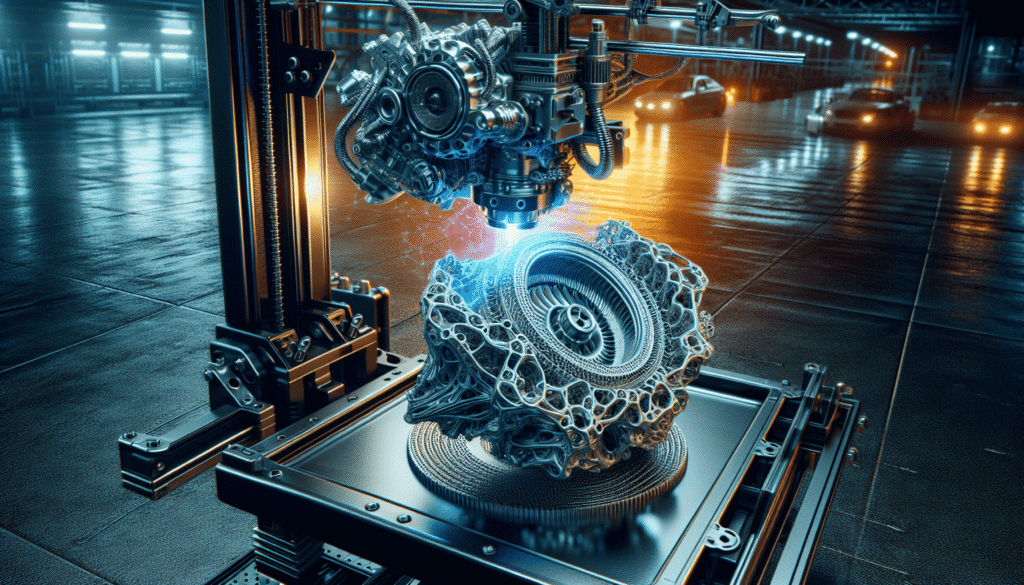

Automotive Industry

The automotive industry—the hustle and bustle of technology in motion—uses hybrid manufacturing to produce complex parts with precision while keeping costs down. It’s like fitting a Formula 1 engine in a classic car, enhancing performance without relinquishing that vintage allure.

Challenges in Integration

While the hybrid approach presents many advantages, integrating two distinct methodologies is not always a walk in the park. Challenges such as equipment costs, technical expertise, and integration complexity emerge as hurdles to be overcome.

Addressing the Challenges

As with teaching an old dog new tricks, it takes time and patience. Investment in training and equipment is essential, as is the willingness to innovate and adapt. Overcoming these challenges is much like persevering through a difficult puzzle—frustrating at times, but rewarding once the pieces fit.

The Future of Hybrid Manufacturing

Looking ahead, the future of hybrid manufacturing seems as bright as a shiny new gadget fresh from the box. The continuous evolution of both 3D printing technology and traditional manufacturing techniques promises boundless opportunities—and it’s not just myself who believes this!

With advancements in materials science and machine learning, hybrid manufacturing systems could become even more efficient and versatile. The integration might expand to include even more sophisticated technologies, creating a seamless and enhanced production process.

Conclusion

Hybrid manufacturing systems are not just a passing trend, but a robust and exciting evolution in the world of production. It’s a beautiful dance between tradition and innovation—each step in harmony, each turn a testament to the power of combining strength with finesse.

As we move toward a future where hybrid manufacturing becomes increasingly prevalent, I find this blend of old and new not just charming but inspiring. Whether it’s the aerospace industry reaching for the stars or the medical field revolutionizing patient care, the walls between conventional and cutting-edge are ever so gracefully crumbling. In this convergence, we witness a transformation of possibilities and a glimpse into the future of production. Isn’t it exciting to think where this innovative journey might lead us next?