Have you ever ordered a product and wondered why it took so long to arrive, or why it sometimes didn’t quite meet your expectations? Imagine a world where products are made just for you, exactly when you need them, without any delays. This futuristic scenario is fast becoming a reality, thanks to the groundbreaking technology of 3D printing. As someone deeply fascinated by this world of innovation, I find myself drawn to the implications it has for our everyday lives and for the businesses we depend on. Let’s embark on an exploration of how 3D printing is not only changing the way we manufacture but also revolutionizing the entire supply chain process.

Understanding 3D Printing

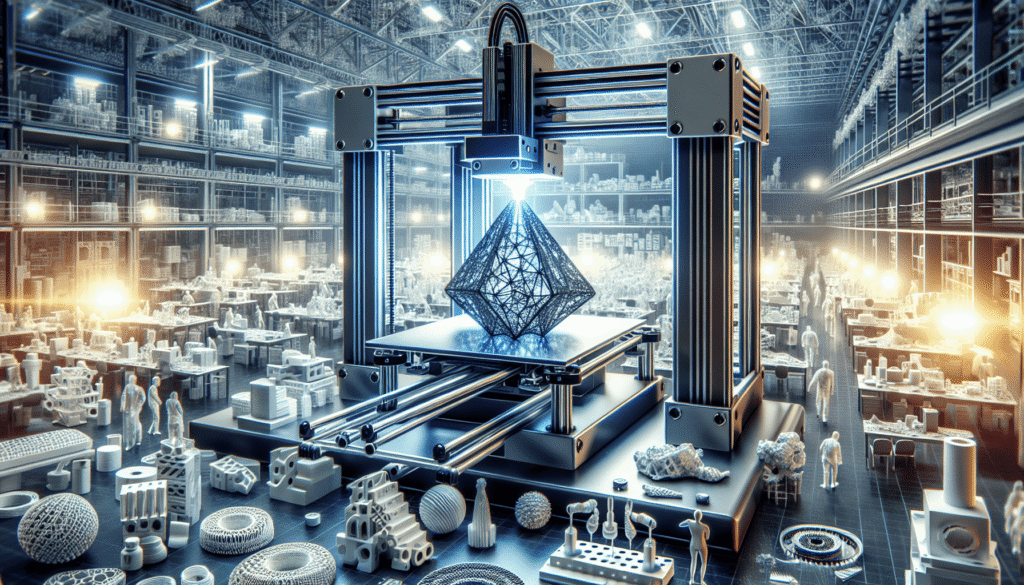

Before we jump into its impact on supply chains, let’s first understand what 3D printing is. In essence, it’s a manufacturing process that creates a physical object from a digital design. Unlike traditional methods, which often involve cutting away pieces from a larger block, 3D printing builds an item layer by layer. This is much like how an artist might slowly sculpt a statue, but with a precision that our hands could never achieve.

How Does 3D Printing Work?

The journey of 3D printing begins with a digital file. This file, often in the form of a 3D model designed using computer-aided design (CAD) software, is sliced into thin layers by the printer’s software. These layers serve as a blueprint for the printer. The printer then deposits material, be it plastic, resin, metal, or even living cells, one layer at a time until the object is fully formed. It’s a beautiful dance between the digital and physical realms, and trust me, once you see a printer in action, it’s hard not to be awestruck.

Types of 3D Printing Technologies

While there’s a single name, “3D printing,” it encompasses several different technologies. Each one uses a unique method to create an object.

-

Fused Deposition Modeling (FDM): The most common and accessible form of 3D printing, where a filament of thermoplastic is heated and extruded through a nozzle.

-

Stereolithography (SLA): Utilizes a laser to cure liquid resin into hardened plastic in a layer-by-layer process.

-

Selective Laser Sintering (SLS): Involves a laser that fuses small particles of powder (a material like nylon) into a solid structure.

-

Digital Light Processing (DLP): Similar to SLA but uses a more conventional light source, like an arc lamp, to cure the resin.

Each of these technologies has its own strengths and weaknesses, and the choice of which to use depends on factors like desired material, cost, resolution, and speed.

The Traditional Supply Chain vs. On-Demand Manufacturing

To truly appreciate the disruption 3D printing brings, it helps to understand the traditional supply chain model. This model is often linear, starting with raw materials that are transformed into products through a series of steps: production, assembly, storage, and finally, distribution. It can be likened to a relay race where each stage waits patiently for the baton before sprinting ahead.

Challenges of the Traditional Model

Traditional supply chains can be rigid and sometimes painful. Why, you ask? Here’s a list for your perusal:

-

Inventory Costs: Companies often produce goods in bulk, leading to large inventories that occupy space and tie up capital.

-

Lead Times: Producing and shipping products can take weeks or months, resulting in longer lead times.

-

Forecasting Risk: Companies have to predict demand well in advance, leading to either excess inventory or stockouts.

-

Geographical Constraints: Products are often manufactured in distant factories, bringing in complications of international shipping, tariffs, and logistics.

-

Environmental Impact: Mass production often leads to excess waste, and the carbon footprint of transporting goods globally is significant.

On-Demand Manufacturing Through 3D Printing

Enter 3D printing, the superhero of on-demand manufacturing. This method promises to alleviate many of the traditional woes by flipping the old model on its head. Instead of producing a large batch of products and storing them until they’re needed, companies can now produce goods only when there’s an actual demand. This shift from “push” to “pull” is refreshing and a game changer.

Evolution of Supply Chains: Impact of 3D Printing

Now that we’ve set the stage, let’s turn to the core topic: how 3D printing modifies supply chains. It’s like watching an intricate performance, where the actors seamlessly adapt to a new play.

Cost Reductions

The financial aspect always catches our attention, doesn’t it? By adopting 3D printing, companies can produce items closer to their customers, saving significantly on shipping and warehousing costs. Gone are the days of producing overseas just for the sake of cheap labor. With 3D printing, the focus shifts to localized production.

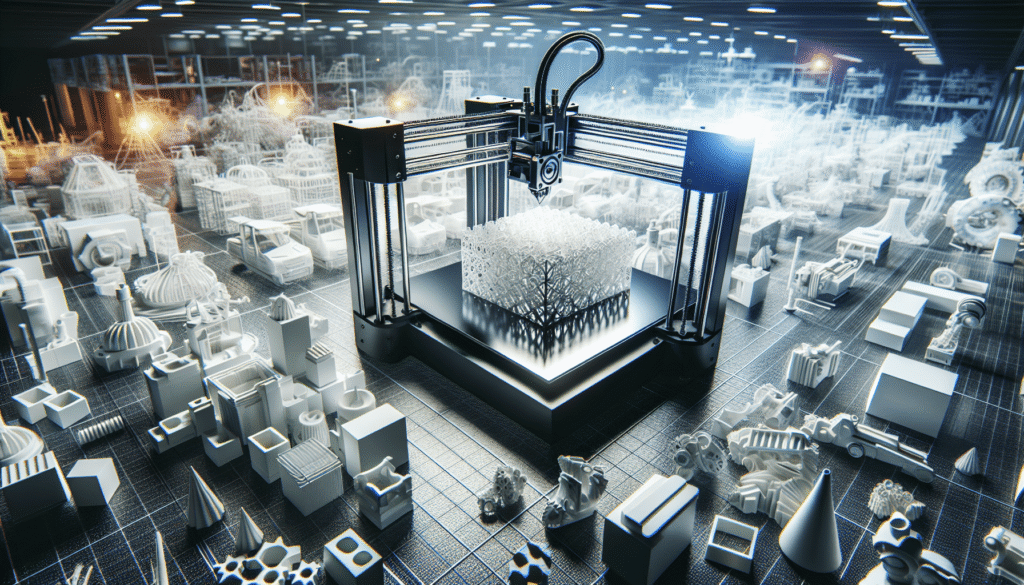

Customization and Flexibility

Today’s consumers crave products that reflect their individuality. 3D printing caters to this desire by enabling easy customization without much additional cost. Whether it’s a shoe designed to the precise contours of your foot or a piece of jewelry with a personal touch, the possibilities are endless.

Beyond customization, 3D printing offers immense flexibility. Manufacturers can swiftly adjust designs without needing to overhaul entire production lines. Need to make a last-minute tweak based on customer feedback? With 3D printing, it’s as easy as editing a digital document. I often wonder, why didn’t we have this luxury sooner?

Speed and Time-to-Market

Time waits for no one, they say, and businesses are no exception. With the capability to produce items on-demand, companies can drastically reduce the time-to-market for their products. This speed means businesses can quickly respond to trends or consumer preferences, staying ahead of the curve and avoiding the pitfalls of obsolete inventory.

Case Studies: Real-World Examples of 3D Printing in Action

It’s one thing to talk about theory and another to see real-world examples. Let’s peek into some industries where 3D printing is making waves.

Healthcare: Customized Prosthetics and Implants

The medical field is a poignant illustration of 3D printing’s impact. Traditional prosthetics are often expensive and time-consuming to produce, but 3D printing offers a more rapid, custom-fitted, and cost-effective solution. Personalized implants, create from a patient’s own medical scans, are becoming the norm, promising better fits and reduced rejection rates.

Aerospace: Lightweight Components

The aerospace industry has always been one of precision and innovation. 3D printing allows for the design and production of complex, lightweight components that traditional methods struggle with. This not only reduces material costs but also contributes to fuel efficiency — a small win for both the environment and airline budgets.

Fashion: One-of-a-Kind Apparel

Fashion is all about standing out. Designers are experimenting with 3D printed textiles, creating unique clothing pieces and accessories that would be impossible to produce using traditional methods. The fashion world’s embrace of 3D printing is a testament to its versatility and promise of bespoke craftsmanship in the mass market.

Automotive: Replacement Parts on Demand

Car manufacturers and repair shops are leveraging 3D printing for producing replacement parts. Instead of waiting for parts to arrive from a distant supplier, a growing number of parts can be manufactured on the spot, reducing downtime for vehicles and storage needs for businesses.

Challenges and Considerations of 3D Printing

As promising as 3D printing is, it’s not without its challenges. These hurdles remind me that even the most wondrous technology still has limitations.

Quality and Durability

While 3D printing is versatile, ensuring consistent quality and durability across printed items can be challenging. The layered nature of 3D printed items sometimes results in weaker structures compared to those made using traditional methods.

Material Limitations

While advancements are made regularly, we’re still a bit limited in the types of materials available for 3D printing. There’s a long way to go before we see the full spectrum of materials that traditional manufacturing enjoys.

Intellectual Property Concerns

With the digital nature of 3D designs comes the potential for intellectual property theft. Once a design is created, there’s a risk it could be copied without permission. This raises concerns about protection and rights in the digital realm.

Cost and Accessibility

While the costs of 3D printers have decreased, high-end models remain expensive. For smaller businesses and individuals, the initial investment and learning curve can be significant barriers.

The Future of 3D Printing in Supply Chains

Where do we go from here, and what does the future hold for 3D printing and supply chains? The terrain is yet uncharted, full of exciting prospects and, undoubtedly, more challenges.

Increased Innovation and Collaboration

Companies are likely to collaborate more, sharing resources, designs, and innovations. Such partnerships can propel 3D printing technology to new heights, fostering a culture of shared growth and success; basically, it’s the jazz of manufacturing.

Expansion to New Sectors

Beyond the obvious industries, 3D printing is bound to enter more sectors. Imagine architecture, where city dwellers could order buildings like pizzas, or food production where meals are printed layer by layer, tailored just for your taste buds.

Environmental Impact

One of the most hopeful aspects of 3D printing is its potential to be more environmentally friendly. By producing items locally and reducing waste, the carbon footprint of manufacturing could significantly decrease. I dream of a future where our beloved planet cheers us on for leaving a softer impact.

Personal Reflection

I’ve always been captivated by the possibilities technology holds for transforming our world. 3D printing, in its essence, is a beacon of that promise. It represents a shift in thinking, away from mass production and towards a model that values customization, efficiency, and responsiveness.

At the same time, it challenges me to ponder the responsibilities that come with such advancement. How do we ensure ethical use of this technology? How do we balance innovation with protection of craftsmanship, originality, and tradition?

Conclusion

As I’m sitting here pondering what the future holds for 3D printing and our supply chains, I can’t help but feel excited. It’s a brave new world out there, and 3D printing is right at the forefront, challenging the status quo and rewriting the rules of manufacturing. We’re witnessing a transformation akin to the dawn of the digital age, where the limits of what we can dream and create seem boundless.

Knowing we’re equipped with the tools of tomorrow today fills me with a sense of hope. Where will the journey of 3D printing take us next? Only time will tell, and isn’t the waiting part of the thrill?