Have you ever found yourself wondering how to choose the perfect 3D printer? If so, you’re not alone. It’s a question that has intrigued many of us who are eager to venture into the world of 3D printing, where possibilities are seemingly endless, yet navigating the sea of options can seem as confusing as piecing together a Lego set without a manual. Today, I’m going to take you on a friendly journey through the intricacies of choosing the right 3D printer, guided by the wisdom of PrintElevate’s 3D Printer Buyer’s Guide Hub. Feel free to grab a warm cup of coffee or tea as we unravel the mysteries together.

Understanding 3D Printing Technology

3D printing, or additive manufacturing, involves creating three-dimensional objects layer by layer using digital design software. This innovative process is revolutionizing industries from healthcare to fashion. But what does it all mean, and how does it work? Imagine a baker icing a cake, layer by layer. In essence, a 3D printer forms an object in much the same way by adding ink-like materials.

Types of 3D Printers

The world of 3D printing is diverse, with various types available, each suited for different tasks. It’s like choosing a pet; not all of us are dog people, you know? Let’s break down the main types of 3D printers, so you can find your ideal match.

-

Fused Deposition Modeling (FDM): These are perhaps the most widespread 3D printers found in homes and schools. They work by extruding thermoplastic filaments through a heated nozzle. They’re like the mini-vans of 3D printers—reliable, durable, and perfect for everyday use.

-

Stereolithography (SLA): While SLA printers use a laser to cure liquid resin into hardened plastic, they are known for high precision and smooth finishing. Imagine a sculptor meticulously chiseling out the finest details—that’s an SLA printer for you.

-

Digital Light Processing (DLP): Similar to SLA, a DLP printer uses a digital light projector to cure resin. The difference akin to comparing a painting to photography—both capture reality, but with a different quality of light.

-

Selective Laser Sintering (SLS): Instead of using liquid resin or filaments, SLS fuses powdered material via a laser. It’s a type that brings to mind a sand castle, where grains are carefully fused together creating something robust.

-

PolyJet and MultiJet Fusion (MJF): With these printers, multiple jets lay down liquid photopolymer which is cured layer by layer. Think of an airbrush artist working on a canvas, applying layers until perfection is achieved.

Key Considerations When Choosing a 3D Printer

Selecting a 3D printer involves considering several factors: purpose, budget, and technical capabilities—to name a few. The endeavor is not unlike matchmaking on a dating app. Let’s delve into what you need to consider:

-

Purpose: Determine why you need the printer. Is it for hobbyist creations or professional prototypes? Your goal will guide your decision.

-

Budget: Like any technology, prices range from the surprisingly affordable to eye-wateringly expensive. We need to balance our dreams with the reality of our wallets.

-

Technical Specifications: Look at printer resolution, build volume, and material compatibility. These specs determine the printer’s abilities—kind of like horsepower for cars.

-

User-Friendliness: Consider how comfortable you are with technology. Some printers are user-friendly, while others require a knack for tech tinkering akin to a watchmaker’s precision.

-

Community and Support: A vibrant user community can be the saving grace of troubleshooting. It’s the difference between calling a friend and a customer service hotline in times of need.

Budget Breakdown: Finding Your Price Point

Let’s face it, pricing can be tricky. It’s similar to finding an affordable entrée at a fancy restaurant that still fills you up—compromise is essential. Here’s a straightforward table to provide a succinct snapshot of the 3D printer market pricing:

| Price Range | Types of Printers | Features & Benefits |

|---|---|---|

| Under $500 | Basic FDM | Great for beginners, limited build volume, simple models |

| $500 – $2,000 | Intermediate FDM | Better quality, bigger build space, some advanced features |

| $2,000 – $5,000 | Advanced FDM/SLA | High precision models, larger builds, professional use |

| Over $5,000 | Industrial SLS/SLA | Exceptional precision, durable, suitable for critical applications |

What You Really Get for Your Money

In the realm of 3D printers, you truly get what you pay for. Tight budget? Expect smaller build volumes and basic features. With a mid-range budget, you’ll find higher quality materials and improved ease. Opt for the high-end models if precision, speed, and reliability are priorities that resonate with the core of your objectives.

The Materials Maze: Navigating Filaments and Resins

Choosing the right printing material can feel like being in a candy store. Do you fancy ABS, PLA, or those flashy photopolymer resins? Each one has its unique charm and purpose, similar to different flavors of candy bars.

Common Printing Materials

-

PLA (Polylactic Acid): Known for its ease of use and environmentally friendly nature, PLA is like the organic fruit bar of 3D printing. Perfect for beginners.

-

ABS (Acrylonitrile Butadiene Styrene): Durable and strong, ABS is the trusty baseball glove among printing materials. It’s great for robust applications but requires a heated bed.

-

PETG (Polyethylene Terephthalate Glycol): Like the sturdy Tupperware of filaments but allows a bit more flexibility. It’s excellent for outdoor applications.

-

Resin: Used in SLA and DLP printers, resins vary widely. The exquisite chocolates of the printing material world, resins deliver high detail finishes but require post-processing.

Material Considerations

Material selection depends not only on printer compatibility but also on your project specifications. Some materials emit fumes requiring ventilation, akin to a little cigar lounge located in your home office. Consider safety and your working environment.

Exploring Advanced Features

Ah, the shiny extras—the turbo button of 3D printers that might not be necessary, but definitely delightful. Advanced features range from wireless connectivity to dual extrusion capabilities, leaving you with possibilities as varied as the characters in a Dickins novel.

Technical Enhancements

-

Auto-Bed Leveling: Removes the hassle of manual leveling. It’s the equivalent of cruise control on your 3D printing journey.

-

Filament Sensors: Alerts you when you’re running low. Think of it as the modern printer’s gas gauge, sparing you the agony of mid-print disasters.

-

Dual Extruders: Allow printing with two materials/colors simultaneously. Imagine an artist with a brush in each hand, painting a picture more vivid than ever before.

Software Integration

Good software is like a competent personal assistant who makes your life effortless. Modern 3D printers are paired with software capable of slicing models, adjusting settings, and sending commands wirelessly, offering you a seamless experience.

The Community Connection

As with most tech, there’s often a cherry-on-top layer of community support that enhances the ownership experience. Forums, online communities, and user groups are invaluable, providing troubleshooting tips, sharing experiences, and offering advice.

Benefits of Community Engagement

Participating in the 3D printing community is like joining a book club, except technology is the main protagonist of your literary adventure. Conversations and collaborations can inspire new ideas and provide moral support during those frustrating moments of failed prints.

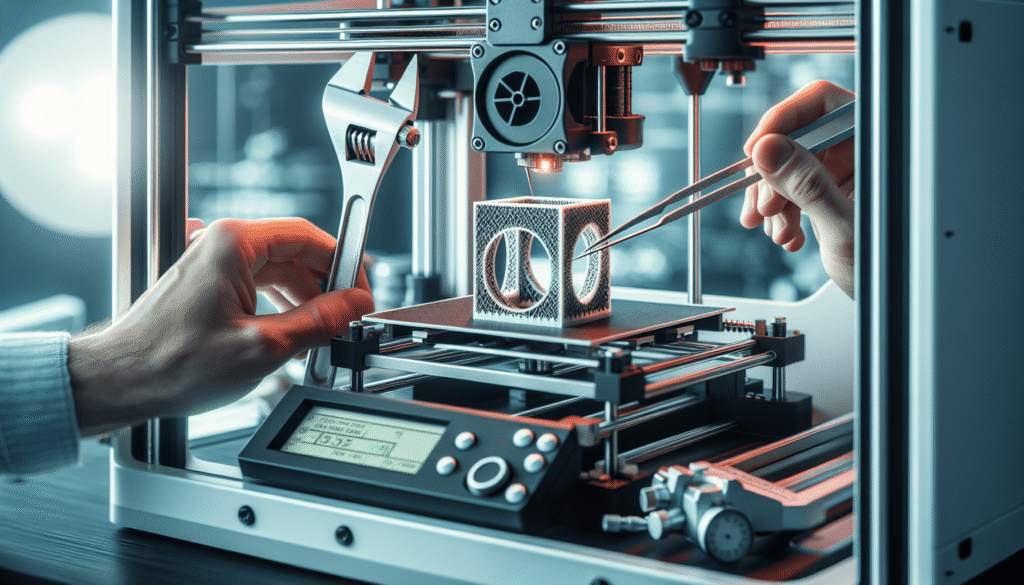

Maintenance and Troubleshooting: Keeping Things Running

Owning a 3D printer is like caring for a pet; maintenance is non-negotiable. Regular cleaning, replacing worn parts, and ensuring everything is in working order are essential to prolong your printer’s life.

Regular Maintenance Tips

Think of your maintenance schedule as your weekly retinue. Just like you’d give your car a wash or take your dog for a walk, your printer needs attention too:

-

Clean the Nozzle: Just like a toothbrush needs regular cleaning, your nozzle benefits from a good cleanse.

-

Lubricate Moving Parts: Avoid squeaky situations with a dab of oil to keep everything running smooth.

-

Check the Bed Leveling: Think of it as weekly yoga—ensuring your foundation is solid can avert disasters.

Troubleshooting Common Issues

No odyssey is complete without bumps along the road. Encountering issues isn’t the end—look at it as a learning opportunity.

-

Print Layer Shifting: Often due to fast printing speed. Slowing down and making sure belts aren’t loose can resolve this.

-

Poor Adhesion: Prints not sticking? Check if your bed is level and clean. It’s akin to making sure your climbing shoes aren’t covered in butter before scaling Everest.

-

Stringing or Oozing: Occurs when material drips between print layers. Adjust retraction settings and ensure temperatures aren’t too high.

Conclusion: Your Printing Odyssey Begins

Choosing a 3D printer is more than a purchase; it’s step one in an adventure fueled by creativity and innovation. Like finding the perfect plot twist to end a mystery novel, I hope this guide has illuminated the path forward. As you step into the world of 3D printing, remember that no question is too simple, and each experience takes you one layer closer to mastery. Whether you’re tinkering, teaching, or transforming industries, may your prints be ever successful and your innovations endless.