Have you ever struggled with those frustrating, unwanted strands of material that seem to cling to your 3D prints no matter what you do? Yes, I’m talking about stringing. It’s a little like when a cat plays with yarn—it looks cute, but leaves a mess that’s not exactly what you were going for. As someone who has spent countless hours coaxing my 3D printer into creating flawless models, I completely understand the challenge. You’re in good company here.

In this discussion, I’ll guide you through the myriad of ways you can prevent stringing in 3D prints. We’ll metaphorically sit down with our printers over a cup of coffee and have a deep conversation with them about what’s going on. I promise, it’ll be like having a heart-to-heart chat, but for technology.

Understanding Stringing

What is Stringing?

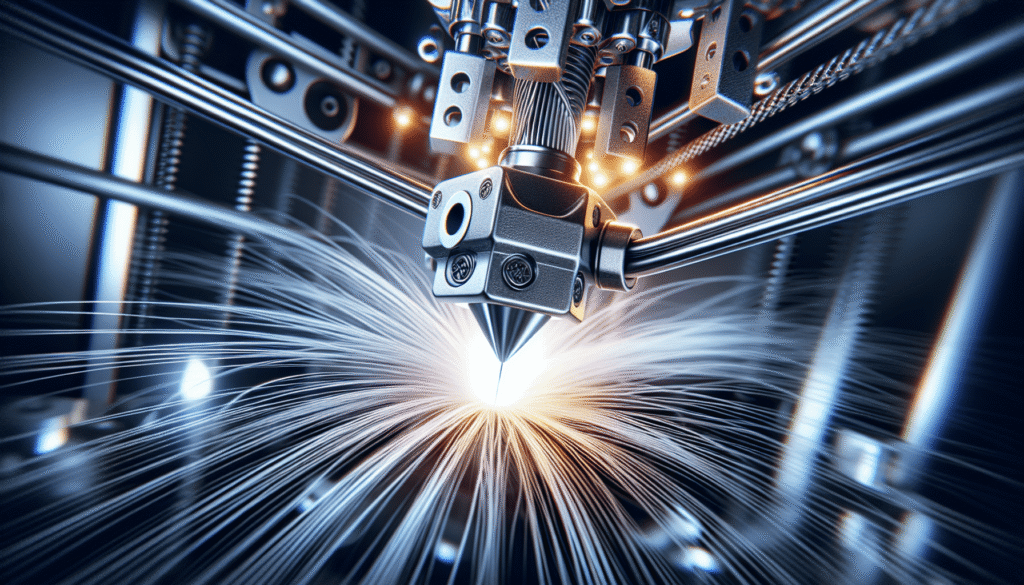

Imagine printing an object, expecting a smooth finish, only to notice thin, wispy strands connecting different parts of your model, much like spider webs. That’s stringing. These delicate strands occur when melted filament oozes out of the nozzle as it moves across open areas.

Why Does it Happen?

There are a few mischievous factors at play here: temperature, retraction settings, and the type of filament. The filament oozes out more at higher temperatures and when the retraction settings aren’t optimized, leading to stringing. Much like eating spaghetti on a windy day, things can get messy if conditions aren’t just right.

Optimizing Printer Settings

Let’s address the elephant in the room—settings. Contrary to popular belief, the printer is as cooperative as a puppy once you understand the settings.

Temperature: The Goldilocks Principle

Just like with porridge, we want the temperature to be just right.

| Temperature Too High | Temperature Just Right | Temperature Too Low |

|---|---|---|

| Excessive stringing | Minimal stringing | Poor layer adhesion |

Dropping the temperature even by just a few degrees can sometimes reduce stringing significantly, so don’t be afraid to experiment a little.

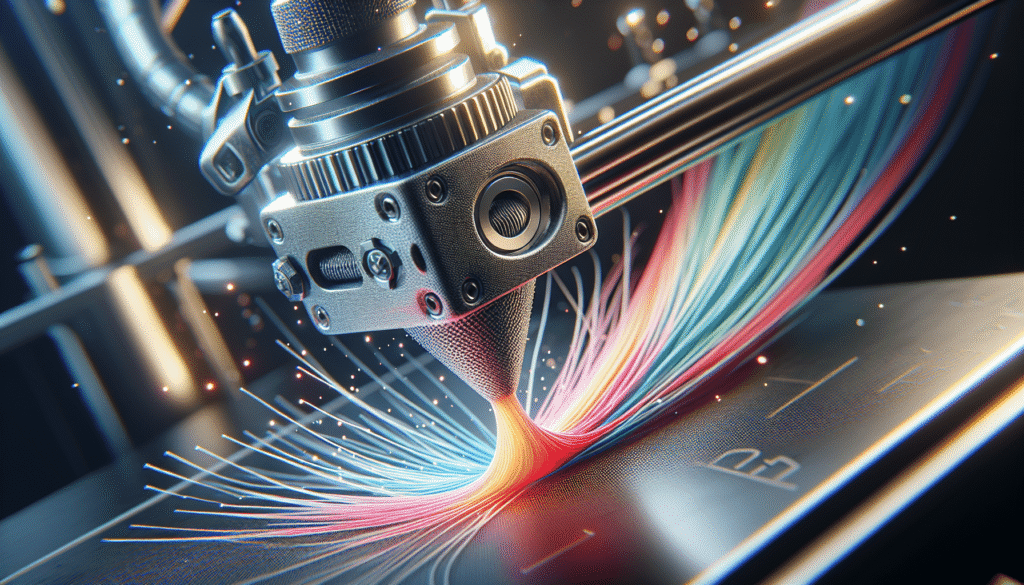

The Importance of Retraction

Retraction is similar to that polite shut-off valve on a garden hose—just a slight tweak can stop unnecessary flow. It determines how much filament is pulled back into the nozzle before moving across a void.

Retraction Settings to Consider

- Retraction Distance: Start by setting it between 2-7mm, adjusting in small increments.

- Retraction Speed: Keep this between 20-50mm/s. Too slow or too fast, and you might find yourself in stringy territory.

Printing Speed and Movements

Imagine running through a sprinkler versus walking. Which keeps you dryer? Speed affects stringing in much the same way.

- Slow Movement: Allows more filament to ooze out.

- Optimal Speed: Strikes a balance to move quickly when crossing spaces. Aim around 60mm/s as a good starting speed.

Choosing the Right Filament

Not all filaments are created equal—some are like the friend who refuses to leave their phone unattended.

Filament Types and Their Misbehaviors

- PLA: Generally behaves well, but can string at higher temperatures.

- PETG: Known rebel of the bunch, more prone to stringing.

- ABS: Tends to be less temperamental regarding stringing but brings along its own set of quirks.

Drying Filament: Say Goodbye to Moisture

Think of moisture in filament as a gremlin, coaxing your printer into stringing all by itself. Using a filament dryer or keeping it stored away from humidity can help keep this problem in check.

Software Tweaks: Your Digital Toolbox

Ah, software. The unsung hero or occasional villain, depending on the day.

Slicer Settings

Most slicing software comes equipped with magical settings that aid in minimizing stringing.

Key Settings

- Combing: Allows non-print moves strictly within a printed area to further minimize stringing.

- Travel Avoidance: Directs the print head to avoid crossing open spaces, thus reducing the chance for stringing.

Advanced Features

Explore features like wipe while retracting and coast at the end. These advanced tricks subtly alter paths to ensure your filament behaves more courteously.

Practicing Good Habits

Here’s where personal discipline and a bit of routine come into play. You wouldn’t go for a run without stretching first, right? A similar principle applies here.

Regular Maintenance

- Keep Nozzles Clean: Ensures a clear path for filament.

- Check for Clogs: Regular checkups prevent unexpected surprises.

Test Prints: The Necessary Nuisance

Running a smaller test print can unearth potential stringing problems without sacrificing an entire roll of filament or your model.

Troubleshooting Common Issues

Small stringing issues might persist despite your best efforts. Here’s a table to guide you:

| Problem | Possible Solution |

|---|---|

| Persistent Stringing | Increase retraction distance/speed |

| Brittle Filament | Dry the filament thoroughly |

| Inconsistent Layer Lines | Check for under/over extrusion |

Final Thoughts

Preventing stringing in 3D prints is like orchestrating a symphony—balancing multiple elements to achieve harmony. You don’t have to be an expert on your first try, and each print will teach something new. Remember, it’s all about finding that sweet spot and encouraging your printer to perform its solo without the unwanted accompaniment of stringy webs.

Now, take these strategies forward with a hopeful heart, a bit like plotting the course of a treasure map where ‘X’ marks perfectly flawless prints. I find there’s nothing quite like the satisfaction of getting it right after some trial and plenty of eye-opening errors. Here’s to minimizing stringing one print at a time!