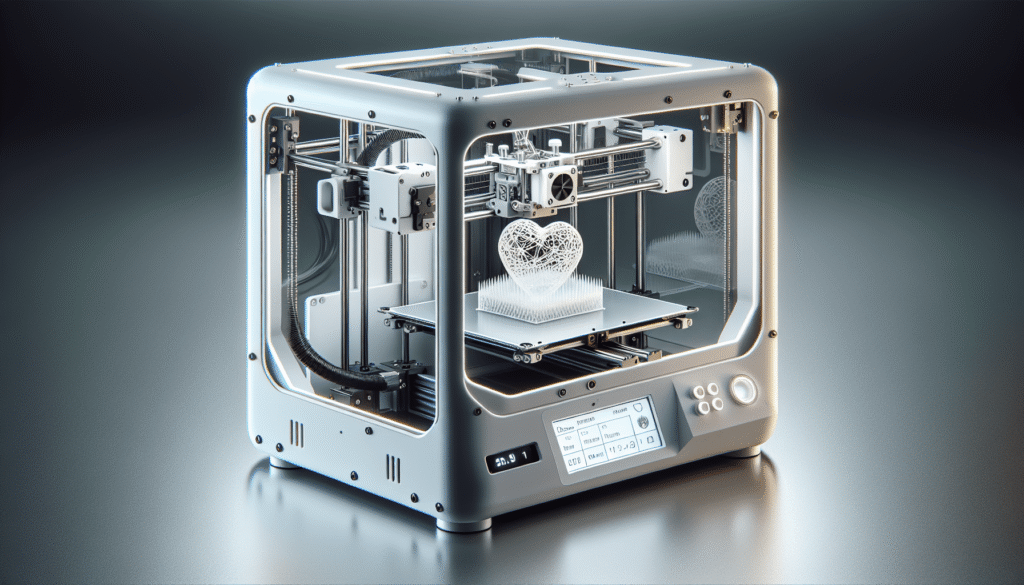

Have you ever wondered what SLA 3D printing is and how it works? You’re in the right place! SLA 3D printing is fascinating, and I’m excited to have a friendly chat with you about it. We’ll break it down so it’s easy to understand, much like savoring a delightful tale.

What Exactly is SLA 3D Printing?

Let’s start at the beginning. SLA stands for Stereolithography, which sounds like something straight out of a sci-fi movie, doesn’t it? But it’s quite straightforward once you get to know it. SLA is one of the most popular types of 3D printing technology, known for its precision and ability to produce intricate designs. At its core, SLA 3D printing uses a laser to transform liquid resin into a solid object, layer by layer. It’s like magic, only it’s not—it’s science!

A Brief History of SLA

The origins of SLA 3D printing date back to the 1980s. Chuck Hull, an American engineer, invented this technology, which was a groundbreaking achievement for manufacturing and design. Hull’s creation allowed for the creation of complex parts directly from digital models without the need for traditional tools or molds. Think of him as the fairy godfather of 3D printing.

How Does SLA 3D Printing Work?

Imagine you’re baking a cake. Instead of pouring the batter into a pan, in SLA, you’re using a laser as a spoon, carefully crafting each layer of cake from liquid. The magic happens in a vat of photopolymer resin. A UV laser traces the shape of each layer, solidifying the resin as it follows the design. This is repeated over and over until your 3D masterpiece is complete. It’s like painting, but in three dimensions and with no colors—just layers.

The SLA 3D Printing Process Explained

Let’s break it down a bit more so it feels like sipping on a hot cup of tea—comforting and easy to digest. SLA 3D printing involves several key steps:

-

Designing the Model: First, you need a digital blueprint, usually created using CAD (Computer-Aided Design) software. It allows you to design intricate details that would be impossible with traditional methods. In this stage, creativity is your only limit.

-

Prepping the Print: The digital model is sliced into thin layers using software. Think of it as slicing delicate layers of apple for a pie. Each layer is a cross-section of your final design.

-

Printing the Model: Here’s where the magic (and science) really happens. The printer’s build platform lowers into a vat of liquid resin. A laser beam traces the shape of each sliced design, solidifying it. Once a layer is solid, the platform lifts slightly to allow a new layer of liquid to coat it, repeating the cycle.

-

Curing the Model: After printing, the object may be a bit gooey, like a batch of freshly cooked gelatin. It needs to be post-cured to harden completely, usually using UV light.

-

Finishing Touches: Often, the model will have supports, like the scaffolding on a building under construction. These are carefully removed, and the surface might be sanded or polished for a perfect finish.

SLA vs. Other 3D Printing Technologies

SLA is just one flavor in the buffet of 3D printing technologies. Let’s compare it with a couple of its cousins, FDM (Fused Deposition Modeling) and SLS (Selective Laser Sintering), to help you see where SLA stands out.

| Aspect | SLA | FDM | SLS |

|---|---|---|---|

| Material | Liquid photopolymer resin | Thermoplastic filament | Powdered materials |

| Resolution | High precision, smooth surfaces | Moderate resolution, visible layers | Good resolution, slightly grainy texture |

| Strength | Good | Strong but anisotropic | Strong and isotropic |

| Speed | Moderate | Fast for larger models | Moderate to slow |

| Cost | Can be expensive due to resins | Generally affordable | More costly due to powdered materials and laser complexity |

SLA excels in detail and surface finish, making it the go-to choice for applications needing precision, like jewelry and dental models. FDM, on the other hand, is often chosen for its affordability and ability to create sturdy parts quickly.

Advantages of SLA 3D Printing

Why would one choose SLA over other methods? Imagine needing a tool that carves out detail finer than the best artist’s brush. That’s SLA for you. Here are some reasons why SLA stands out:

-

High Precision: SLA can create extremely detailed and complex geometries. It’s like having the ability to carve intricate designs into egg shells without breaking them.

-

Smooth Surface Finish: The layers in SLA prints are much finer than in other types of 3D printing, resulting in smooth and detailed surfaces straight off the printer.

-

Material Versatility: SLA resins come in various types, including flexible, transparent, and high-temperature resistant, catering to different needs.

-

Fast Prototyping: For projects requiring detailed prototypes quickly, SLA can be a game-changer. It’s great for proof-of-concept models that you can hold and analyze.

Challenges with SLA 3D Printing

Before you get carried away thinking it’s all sunshine and roses, there are some challenges too:

-

Material Costs: The resins used in SLA can be expensive compared to other 3D printing materials. It’s like wanting to cook with truffles—they’re exquisite but come at a cost.

-

Post-Processing: SLA prints require additional steps like cleaning and curing, which can add time to your project timeline.

-

Durability: While SLA prints look amazing, they may not be as strong under stress as those made with other methods like FDM—like choosing between a beautiful, fragile vase and a sturdy stone one.

Popular Applications of SLA 3D Printing

Thinking about what’s possible with SLA? The possibilities are almost as endless as the stars on a clear night. Here are a few fields where SLA shines brightly:

-

Dental and Medical: Custom braces, crowns, and models for surgeries are often made using SLA, thanks to its precision.

-

Jewelry: Designers can create prototypes and molds with remarkable detail, letting them craft beautiful pieces before finalizing them in precious metals.

-

Prototyping: Engineers and designers appreciate the ability to quickly turn designs into physical models to test and refine their ideas.

-

Scale Models and Miniatures: Hobbyists and professionals create highly detailed models for games and displays—think tiny replicas of grand buildings and figurines.

Choosing the Right SLA 3D Printer for You

Selecting an SLA printer can feel a bit like choosing a pet—you want the one that fits perfectly into your life. Here are some factors to consider:

-

Build Volume: How big do you need your prints to be? SLA printers come in varying sizes, so choose one based on your project needs.

-

Resin Types: Think about the types of materials you’ll need. Some printers are more versatile in handling different resin types than others.

-

Resolution and Precision: Consider how detailed your objects need to be. Printers with finer laser beam widths can achieve better detail.

-

Budget: Last but not least, consider how much you’re willing to spend. Balance your needs with your budget—like choosing between a simple goldfish or a rare exotic breed.

Keeping Up with the Trends in SLA 3D Printing

The world of SLA 3D printing is as vibrant as a bustling market with sights and sounds pulling you in every direction. Staying updated on trends ensures you harness the latest advancements:

-

Material Innovations: New resin formulations offer improved strength, flexibility, and bio-compatibility, continuously expanding what’s possible.

-

Improved Speeds: Faster curing technologies are making SLA 3D printing faster, which is exciting for industries needing rapid turnarounds.

-

Eco-Friendly Options: As the world turns towards sustainability, biodegradable and recyclable resins are becoming more accessible, which is wonderful news for our planet.

-

Software Advancements: With smarter slicing software, optimization, and automation, your prints can come out better while you spend less time managing them.

Tips for SLA 3D Printing Success

You might still feel a bit like Bambi on ice when it comes to SLA 3D printing, but don’t worry! Here are some tips that can make the journey smoother:

-

Experiment with Resins: Not all resins are created equal. Test different types to find those that best meet your needs.

-

Maintain Your Printer: Keep your machine in tip-top shape. Regular cleaning and calibration ensure it runs smoothly, like oiling a well-loved bicycle.

-

Optimize Designs: Use software to analyze and optimize your models’ structure. This can prevent print failures and save material.

-

Practice Patience: Like making perfect pasta dough, practice and persistence are key. Don’t rush through the process; take the time to finesse each step.

-

Embrace the Community: Engage with other SLA enthusiasts. Forums and meet-up groups are great places to learn, share, and grow your skills.

Conclusion

SLA 3D printing is a world full of creativity and possibility, like an open canvas awaiting your artistic flair. From its remarkable precision to its array of applications, it offers a gateway to bringing the extraordinary into our everyday lives. Whether you’re considering diving in as a hobbyist or seeking solutions for professional projects, understanding SLA will set you on a path of creation where each layer brings you closer to your vision. My hope is that this friendly little chat about SLA 3D printing has sparked your curiosity and inspired you to explore further—to see for yourself what wonders you can create, layer by intricate layer.