Have you ever wondered how the magic of 3D printing comes to life? While contemplating this modern marvel, I stumbled upon the array of technologies that power our printers: FDM, SLA, and DLP. These aren’t just random letters from a secret coding, but technologies that define how materials transform into printable reality. Let me take you on a friendly journey through this fascinating world.

What is 3D Printing?

Let’s start at the beginning. 3D printing, or additive manufacturing, is a process where a printer creates a three-dimensional object by layering material based on a digital model. Imagine a baker meticulously layering a cake, but instead of frosting, we’re using intricate materials to form an object. The possibilities are almost as endless as flavors in an ice cream shop.

The Evolution of 3D Printing

Once a concept confined to the realms of science fiction and laboratories, 3D printing has evolved into a versatile technology that’s used in numerous industries. From medical implants to automotive parts, and even custom-designed footwear, it feels like every day, someone uses 3D printing to turn fantasy into tangible reality.

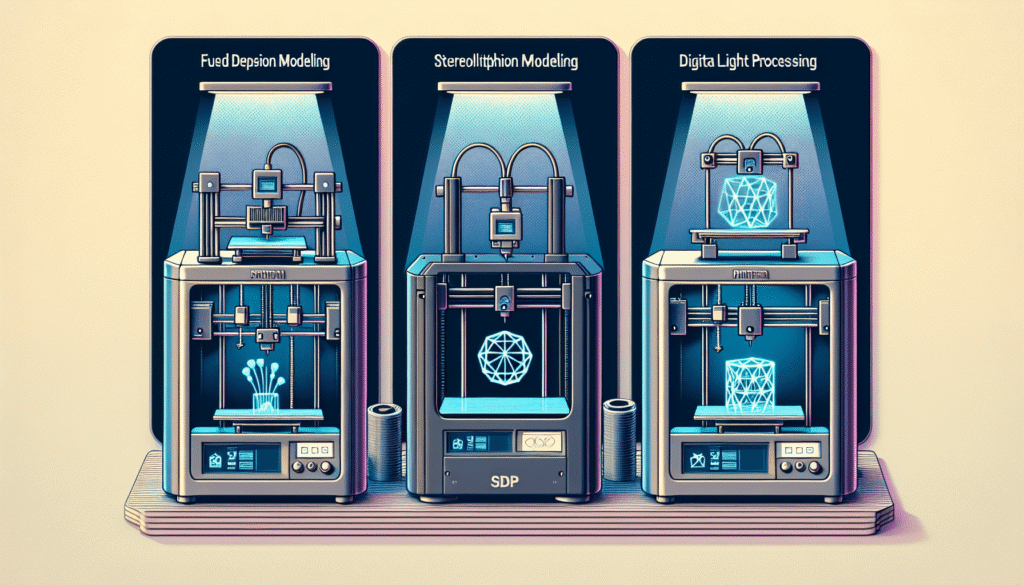

Introducing the Players: FDM, SLA, and DLP

Now, let’s meet our key players: FDM, SLA, and DLP. Each technology offers unique characteristics and caters to different needs.

FDM (Fused Deposition Modeling)

First on this technological stage is Fused Deposition Modeling (FDM). It’s like the gentle giant of the group—known for its simplicity and accessibility. FDM works by extruding thermoplastic filaments heated to their melting point and deposited layer by layer. This technology is often favored by hobbyists and small businesses due to its user-friendly nature and affordability.

Benefits of FDM

- Affordability: Let’s face it, the price tag matters. FDM printers are typically cheaper than their counterparts, making them a favorable choice for beginners.

- Material Options: With a wide range of thermoplastics to choose from, including PLA, ABS, and PETG, the world of FDM offers flexibility in printing materials.

- Ease of Use: As straightforward as arranging a cereal box tower, FDM requires less technical diving compared to its more complex cousins.

Drawbacks of FDM

- Lower Resolution: If you’re aiming for intricate, detail-oriented prints, FDM might not be the superstar in this department.

- Post-Processing Needs: Sometimes, achieving a smooth finish means adding extra steps beyond printing.

SLA (Stereolithography)

Enter Stereolithography (SLA), the sharp and precise sibling. SLA uses a laser to cure liquid resin into hardened plastic in a meticulous layer-by-layer fashion. It’s like watching a sculptor chisel a masterpiece out of marble.

Benefits of SLA

- High Resolution: Perfect for intricate designs or detailed models, SLA can create prints with fine details and smooth surfaces.

- Material Variety: Did someone ask for specialized materials? SLA obliges with a variety of resins, including those mimicking different textures or mechanical properties.

Drawbacks of SLA

- Costly Materials: Like any gourmet dish, SLA demands premium ingredients, which can lead to higher material costs.

- Complex Setup: This isn’t just a push-button operation—setting up an SLA printer requires more precision and understanding.

DLP (Digital Light Processing)

Lastly, jumping into the spotlight is Digital Light Processing (DLP), another light projector-based technology that also uses resin, similar to SLA. The difference? DLP uses a digital light projector screen to flash a single image of each layer across the platform. Think of it as a cinematic approach to printing.

Benefits of DLP

- Speedy Process: Thanks to its technology, DLP can be faster than SLA, making it ideal when time isn’t on your side.

- High Resolution: DLP, like SLA, excels with detailed and smooth prints.

Drawbacks of DLP

- Limited Build Volume: Want to print something large? DLP might need more than a screen adjustment.

- Higher Costs: The speed and precision come at a price that might pinch your budget.

Comparison Table of FDM, SLA, and DLP

To lay it all out clearly, here’s a helpful table comparing these three technologies based on key aspects:

| Feature | FDM | SLA | DLP |

|---|---|---|---|

| Cost | $$ | $$$ | $$$ |

| Material Cost | Low | High | High |

| Resolution | Low to Medium | High | High |

| Speed | Medium | Medium | High |

| Ease of Use | Easy | Moderate | Moderate |

| Ideal For | Beginners, Prototyping | Intricate Designs | Fast Prototyping |

Choosing the Right Technology

When deciding which 3D printing technology suits your needs, consider what matters most: is it the detail? The speed? Or perhaps the cost? Much like choosing the best kitchen appliance, understanding the primary function of each technology ensures you make the right choice.

Hobbyists and Small Businesses

For the tinkerers and small creators among us, FDM is like the cozy sweater you reach for on a chilly day. It’s warm, familiar, and does the job without too much fuss. Ideal for those starting in the 3D printing world or for small to medium project needs.

Medical and Dental Applications

SLA and DLP step into the limelight here, especially where detail and precision are critical. Whether printing dental models or intricate components of medical devices, these technologies’ high resolution is non-negotiable. Isn’t it fascinating to think that your dentist might be using this cutting-edge technology?

Industrial and Professional Use

For industries where precision meets speed, such as in jewelry making or when speed is as important as detail, DLP takes center stage. Its ability to quickly produce high-quality prints makes it indispensable in environments where time is precious.

The Future of 3D Printing Technologies

Just when you think the stage is set, the future promises even more innovations in 3D printing. Researchers and companies are continually pushing boundaries, experimenting with new materials, and enhancing existing technologies. Perhaps one day, we’ll even be able to print on an atomic level, making even the most intricate lace look like child’s play.

Innovations on the Horizon

New composite materials, sustainability efforts, and further miniaturization and portability of printers are just a few exciting areas to watch. As these technologies become more accessible and diverse, the applications and possibilities continue to expand.

Conclusion: Picking a Star

Selecting between FDM, SLA, or DLP is very much like deciding what to watch on movie night. Each has its plot twists and specialties, catering to different tastes and needs. Whether you need speed, detail, or affordability, one of these technologies will indeed become your blockbuster choice.

As we wrap up our exploration of 3D printing technologies, if you ever feel the urge to create something extraordinary, remember: you’re only a few clicks away from turning imagination into reality, one magical layer at a time.