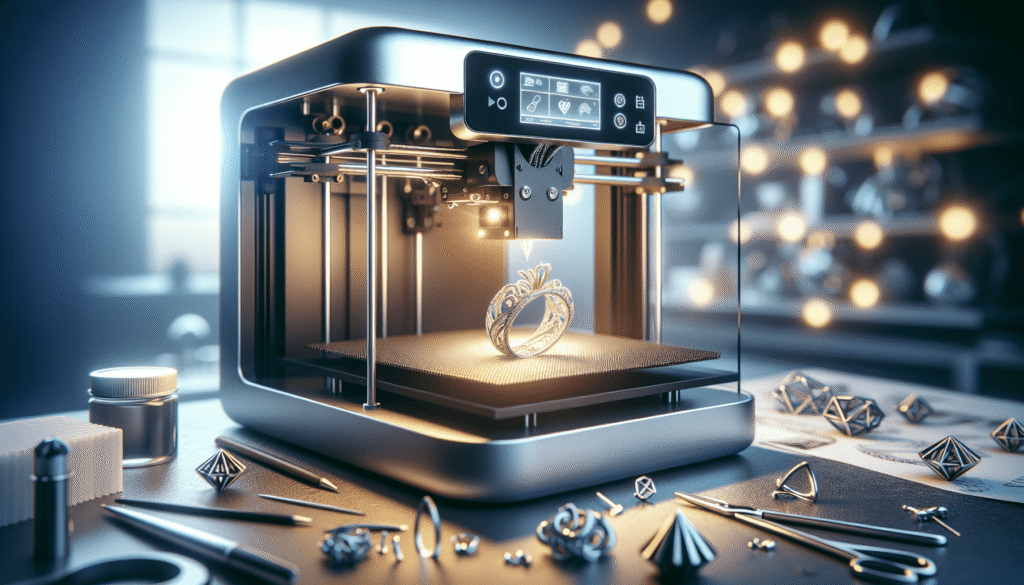

Have you ever wondered how those intricate jewelry designs take form before making their way into stores or onto someone’s finger? It’s a fascinating world of creativity and technology coming together in ways that seem almost magical. Speaking as both an admirer of craftsmanship and someone who spends entirely too much time thinking about how things work, I’m delighted to guide you through the labyrinth that is selecting the right 3D printer for jewelry design and prototyping.

The Intersection of Artistry and Technology

Before we dive into the specifics of various 3D printers, let’s take a moment to appreciate the transformative impact this technology has on jewelry design. The traditional methods involved endless hours of delicate carving or shaping, often followed by casting processes that left little room for error. Imagine the pressure! Now, with 3D printing, designers have the creative freedom to experiment with designs, refine them, create prototypes, and swiftly adjust them before committing to the final version.

Why 3D Printing in Jewelry?

Why exactly should one embrace 3D printing for jewel crafting? Think of it as a tool that enables precision and creativity to coexist seamlessly. Items that would be nearly impossible to shape by hand can manifest with the click of a button. Want to try something avant-garde? No problem; a 3D printer can handle that. Efficiency, innovation, and the reduction of wasteful practices are just a few reasons to consider this leap into the future.

Key Features to Consider in a 3D Printer for Jewelry

With several options in the market, it can be overwhelming trying to figure out which 3D printer can best serve your ambitions in jewelry design. Thankfully, I’m here to unravel some of that confusion for you. Let’s explore what features are critical in defining the ideal 3D printer for this creative endeavor.

Precision and Resolution

When it comes to creating detailed jewelry, high precision is non-negotiable. Each delicate contour and intricate detail requires this feature. The resolution of a 3D printer—the capacity to print complex geometries—is paramount. In simple terms, think of it as an artist’s ability to see and replicate the finest details of their muse.

Material Compatibility

One mustn’t forget the materials. Resin and wax are frequently used in jewelry-making, so if the printer doesn’t play well with these mediums, it’s a bit like trying to build a sandcastle out of bricks. Ensure your chosen printer can handle the materials suited to your designs.

Printer Speed

Speed might seem like a secondary consideration, but in a fast-paced world, efficiency is key. The quicker a prototype can be produced, the faster a designer can move from imagination to reality. Finding that balance between speed without sacrificing accuracy is a delicate dance.

Software and Ease of Use

The brains behind the operation, software works by turning your art into something the machine can create. Selecting a printer with intuitive software can save a lot of headaches and time. The easier a printer is to use, the more time you can spend on actually being creative.

Size and Build Volume

In the context of jewelry-making, size does matter, albeit differently from what is typically expected. While the printer shouldn’t require its own room, a modest build volume is necessary to accommodate intricate designs. Evaluating the build area ensures you can print pieces of the scale you envision without limitations.

Comparing the Top 3D Printers for Jewelry Design

Now comes the revealing part—identifying which 3D printers stand out when it comes to creating jewelry. I’ve compiled an informed selection to satisfy even the most discerning jeweler. Let’s break down these options so you can see them side by side.

| Printer Model | Precision/Resolution | Material Compatibility | Printer Speed | Ease of Use | Build Volume |

|---|---|---|---|---|---|

| Formlabs Form 3BL | 25 microns | Resin, Wax | Fast | User-friendly | 145 x 145 x 185 mm |

| Asiga MAX | 27 microns | Resin, Wax, Polymer | Moderate | Slightly complex | 119 x 67 x 76 mm |

| Solidscape S500 | 5 microns | Wax | Slow | Complex | 152 x 152 x 152 mm |

1. Formlabs Form 3BL

The Formlabs Form 3BL is the dependable workhorse of the 3D printing world. It offers striking precision and supports a broad spectrum of materials essential for jewelry-making. Praised for its user-friendly interface, the Form 3BL makes it easy for newcomers and seasoned creators alike. Its generous build volume also ensures you won’t be limited by size when inspiration strikes.

2. Asiga MAX

Next on the list is a gem for those who appreciate versatility in material use. The Asiga MAX, although slightly more complex to navigate than the Formlabs, makes up for it with its superior material compatibility. While the speed isn’t its strong suit, the resolution is commendable, perfect for crafting those more detailed pieces that require extra consideration and care.

3. Solidscape S500

Renowned for its extraordinarily detailed prints, the Solidscape S500 is unparalleled in resolution. This intricate system is perfect for master jewelers who demand the finest detail in their work. Although it has a steeper learning curve, for those who prioritize precision above all else, it offers unparalleled results. Its slower speed is a faint shadow when compared to the pristine results it achieves.

Understanding the Workflow: From Design to Prototype

While choosing the right printer is critical, understanding the entire workflow from design to prototype can add clarity to your journey. After all, a printer without a plan is like a sailboat without wind. Let’s explore how these steps flow together.

Designing Your Masterpiece

The journey begins with a spark of creativity, often sketched out or designed using CAD (Computer-Aided Design) software. These digital blueprints are critical, translating your ideas into a format a 3D printer can understand. Software such as RhinoGold or MatrixGold are popular among jewelers due to their specialized tools for creating intricate designs.

Preparing for Printing

Once your design is ready, the next step is slicing—an essential process where CAD designs are broken into horizontal layers. These files instruct the 3D printer on how each layer will build. Slicer software, usually included with your printer, plays a crucial role in maintaining accurate dimensions and managing supports, ensuring a successful print without structure failures.

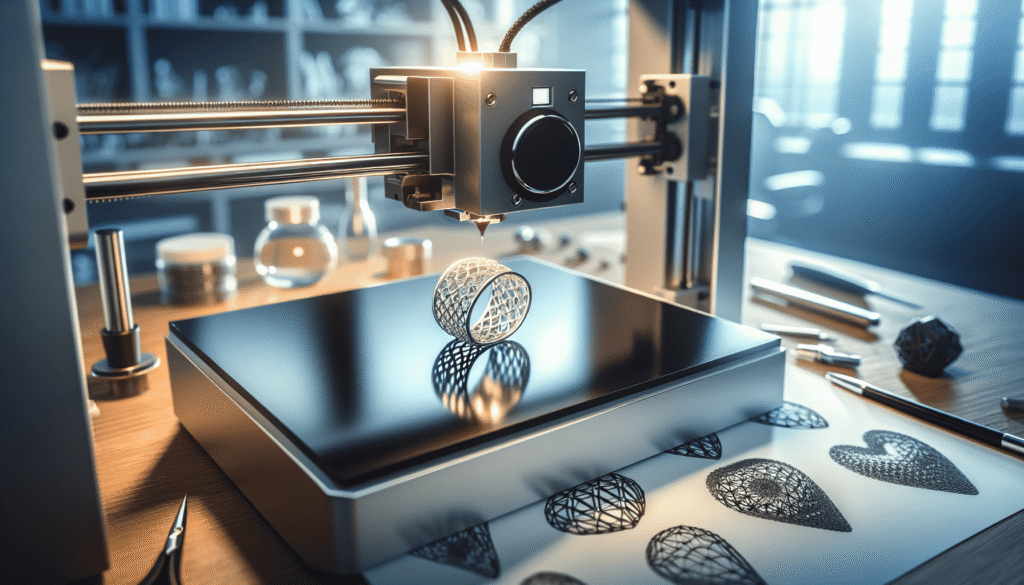

Printing the Prototype

With the groundwork laid, it’s time to bring the creation into the physical realm. Here, patience is a virtue, as each tiny layer builds incrementally. Monitor the process to spot any hiccups. It’s like baking; you wouldn’t just throw a cake in the oven and hope for the best—it requires some level of surveillance.

Post-Processing

After the printing comes an equally important stage: post-processing. This involves removing any supports, refining rough edges, and curing if resin printing is involved. This step ensures the piece is ready for casting if it’s a prototype or finished as a standalone model.

Making the Right Choice for Your Needs

Considering the variety of options out there, selecting the right printer becomes a balancing act of specifications, budget, and personal preference. Reflect on your primary needs—whether you seek precision, speed, or versatility. Also, consider the common materials you plan to use and their compatibility with your chosen printer.

Budget Considerations

Sometimes budget constraints can feel like a heavy weight, but rest assured, there is a printer for every price range. It’s about making intelligent compromises. Meanwhile, considering operating costs—such as materials and maintenance—can prevent budgetary surprises.

Evolving With Technology

As technology continues to evolve, keep an eye out for new advancements in 3D printing. Staying informed can ensure you make future proof investments. Remember, today’s innovation might be replaced by tomorrow’s breakthrough.

Conclusion

The journey into the realm of 3D printing for jewelry design is one of boundless possibilities. While choosing the right tool might seem daunting, the thrill of turning ideas into tangible works of art is worth every minute spent navigating this intricate landscape. Allow your creativity to thrive, armed with the perfect 3D printer to suit your needs, and every piece you create will be a testament to both your vision and the wonders of technology.