Have you ever wondered what the world of 3D printing will look like in the year 2025? It’s like trying to predict the next viral dance craze—everyone’s fascinated, but no one knows just how it will happen. The truth is, the world of 3D printers is ever-evolving, and by 2025, we’ll be seeing some incredibly advanced models that redefine what’s possible. Grab your favorite beverage, kick off your shoes, and let’s talk all things high-end 3D printing.

The Evolution of 3D Printing

It’s amazing how technology evolves faster than we can say “flux capacitor.” High-end 3D printers have transitioned from being garage-bound wonders to full-scale industrial marvels. Back in the day, few envisioned a future where a 3D printer could produce intricate designs with the tiniest details, and yet, here we are.

The Basics of 3D Printing

Before we delve into the crème de la crème of 2025, let’s revisit what 3D printing involves. Essentially, 3D printing or additive manufacturing creates objects by adding material layer by layer, based on digital models. Sounds like digital magic, doesn’t it? Whether it’s using plastics, metals, or composite materials, the possibilities are as limitless as your imagination.

The Rise of High-End Models

High-end 3D printers are not just for making prototypes anymore. With advancements in materials and precision, they’re paving their way into cutting-edge fields like aerospace, medicine, and even gourmet cooking! Imagine eating a 3D-printed dessert that’s perfect in every dimension—not that I need any help finishing my desserts.

What Defines a High-End 3D Printer?

When it comes to high-end 3D printers, we’re talking about craftsmanship that would make a Swiss watchmaker swoon. But what specifically sets these apart? A few essential factors make these printers stand out like peacocks in a field of pigeons.

Precision and Speed

First and foremost, precision and speed are the twin towers of high-end 3D printing. Imagine being able to print with such precision that each layer is as fine as a strand of hair. By 2025, expect this precision to reach new heights, crafting designs faster yet more accurately than ever before.

Versatility of Materials

The ability to print in multiple materials is another hallmark. We’re not just dreaming about plastics anymore. We’re talking ceramics, metals, and advanced composites. These machines bring versatility to another level, opening up the potential for mixed-material objects that solve real-world problems.

Software Integration

Gone are the days of clunky interfaces. Today’s high-end 3D printers boast seamless software integration that practically whispers sweet nothings to your design files. In 2025, anticipate artificial intelligence playing a prominent role in optimizing printing processes, making the machines smart and easy to operate.

The Contenders: Best High-End 3D Printers in 2025

Now, let’s zero in on what you really want to know: which high-end 3D printers will be reigning supreme by 2025. The competition is fierce, with each contender offering unique features that out-Madonna the rest.

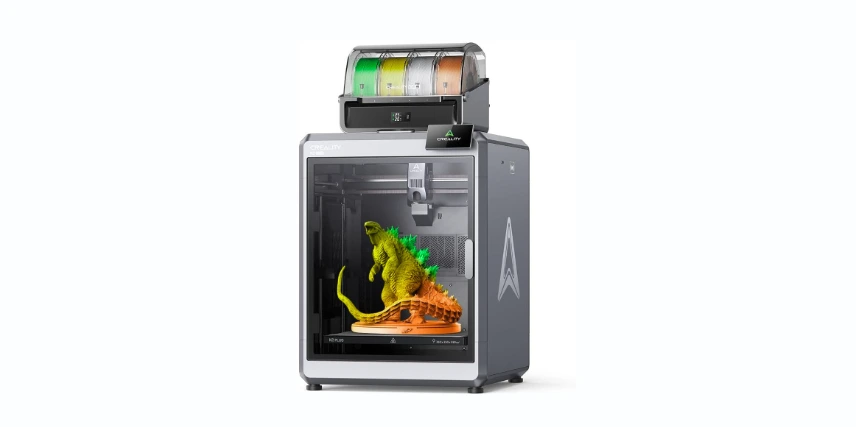

3D Printer X2000

If printers could strut, the X2000 would catwalk all the way down the red carpet. Whatever its makers did under the hood, it worked, as this beast manufactures with unparalleled precision.

- Precision: 0.01mm

- Speed: 150mm/s

- Materials: Plastics, Metals, Ceramics

- Special Feature: Multimaterial capabilities that allow for complex hybrid prints.

FabForge Pro Max

Flaunting a name that sounds like it shouldn’t be operating heavy machinery, the FabForge Pro Max impresses nonetheless. It offers unparalleled speed without compromising on detail and quality.

- Precision: 0.012mm

- Speed: 200mm/s

- Materials: Advanced polymers, Metals

- Special Feature: Built-in AI optimization for reduced printing time.

Vertex Ultima

For those who enjoy blending technology and elegance, the Vertex Ultima is a masterpiece. If the word ‘Ultimate’ had a 3D printer version, this would be it.

- Precision: 0.015mm

- Speed: 180mm/s

- Materials: Biocompatible materials, Ceramics

- Special Feature: Smart diagnostic features predicting material flow issues.

| Printer Model | Precision | Speed | Materials | Special Feature |

|---|---|---|---|---|

| X2000 | 0.01mm | 150mm/s | Plastics, Metals, Ceramics | Multimaterial capabilities |

| FabForge Pro Max | 0.012mm | 200mm/s | Advanced polymers, Metals | AI optimization |

| Vertex Ultima | 0.015mm | 180mm/s | Biocompatible materials, Ceramics | Predictive diagnostics |

Challenges and Innovations on the Horizon

The journey to 2025 is peppered with challenges. Yet, where there are challenges, there are innovations lurking around the corner.

Sustainable Printing

In this age of environmental awareness, finding sustainable resources for 3D printing is crucial. Many companies are investing in eco-friendly materials and energy-efficient processes. By 2025, you might even get your hands on machines that use recycled material exclusively.

Improved Bioprinting

Bioprinting—3D printing of human tissues—has been gaining traction. The possibilities for this technology are as grand as a Hollywood set designer’s wildest dreams. Organ transplants, tissue repair, and personalized medicine could very well become regular interventions, thanks to innovations in this sector.

Automation and AI

We’re straddling an age where automation is set to revolutionize how devices operate. The fusion of AI with 3D printing technology might eliminate the need for manual oversight, allowing the intricacies of design and printing to be automated seamlessly. Think of it as giving your printer a brain of its own.

The Impacts of High-End 3D Printing

The impact of high-end 3D printers is like a ripple in a pond; it extends far beyond the realm of tech enthusiasts and hobbyists.

Revolutionizing Industries

Industries are being transformed by high-end 3D printers. Whether it’s aviation using lighter, 3D-printed components or the auto industry creating complex parts efficiently, the scope is vast and deeply impactful.

Empowering Creativity

The democratization of design is heartening. Artists and creators are unleashing their creativity without the constraints of traditional manufacturing. With versatile software, even non-engineers can let their imaginations drive innovation.

Education and Training

Education institutions are integrating 3D printing into their curriculum. Imagine students not just reading about a robotic arm, but actually designing and printing one. The hands-on learning experience is simply a game-changer.

Conclusion

As we stand at the threshold of 2025, the transformation of high-end 3D printing is undeniably exciting. These advancements promise to make life easier, more imaginative, and far more creative than the protagonist of a sci-fi novel ever envisaged.

It’s exhilarating to think of what the future holds, from sustainable advancements, through seamless AI integration, to the boundary-pushing designs that are yet to become reality. These high-end 3D printers aren’t just machines; they are marvels of innovation that inspire dreamers, creators, and tinkerers alike.

So, as the curtains of 2025 open to a world of technological brilliance, here’s an invitation to imagine, create, and redefine possibilities with the best high-end 3D printers. After all, the future isn’t just where we’re going—it’s what we’re building on the way there.